Must-Have Car Wire Connector Types for Every Mechanic

Wire connectors of the automotive type play a crucial role in car repairs. They ensure that electrical systems function efficiently and safely. Selecting the appropriate type of wire connectors is essential for mechanics, as it simplifies tasks and prevents issues from arising. While electrical connectors are necessary, choosing the wrong ones can lead to complications. It's important to consider their strength and compatibility to avoid errors. Understanding the significance of these connectors helps you make informed choices, enhancing the quality and safety of your automotive projects.

Understanding Car Wire Connectors

Definition and Purpose

What are car wire connectors?

Car wire connectors are key parts of a car's electrical system. They link circuits so power and signals move easily in the car. These connectors have different shapes and sizes for single or many wires. They keep connections safe and reliable, helping your car's electrical parts work well.

Why are they important for mechanics?

Mechanics need to know about these wire connectors. They make fixing electric systems easier. Connectors keep connections stable, stopping electrical problems. Using the right ones avoids issues from loose or bad connections. This helps mechanics work better and keeps cars safe and dependable.

Basic Features

Material and durability

When picking wire connectors, think about their material and strength. Good connectors use materials that conduct electricity well and don't rust. This means they can handle heat, wetness, and shaking. OEM wiring connectors are made with strong materials that last in tough conditions, ensuring steady electric links.

Compatibility with different car models

Compatibility is also important for these wire connectors. They meet industry rules to fit well with other parts. Weatherproof ones have seals to block water, dust, and shaking, fitting many car types. Choosing the right connector for each vehicle ensures good electric links.

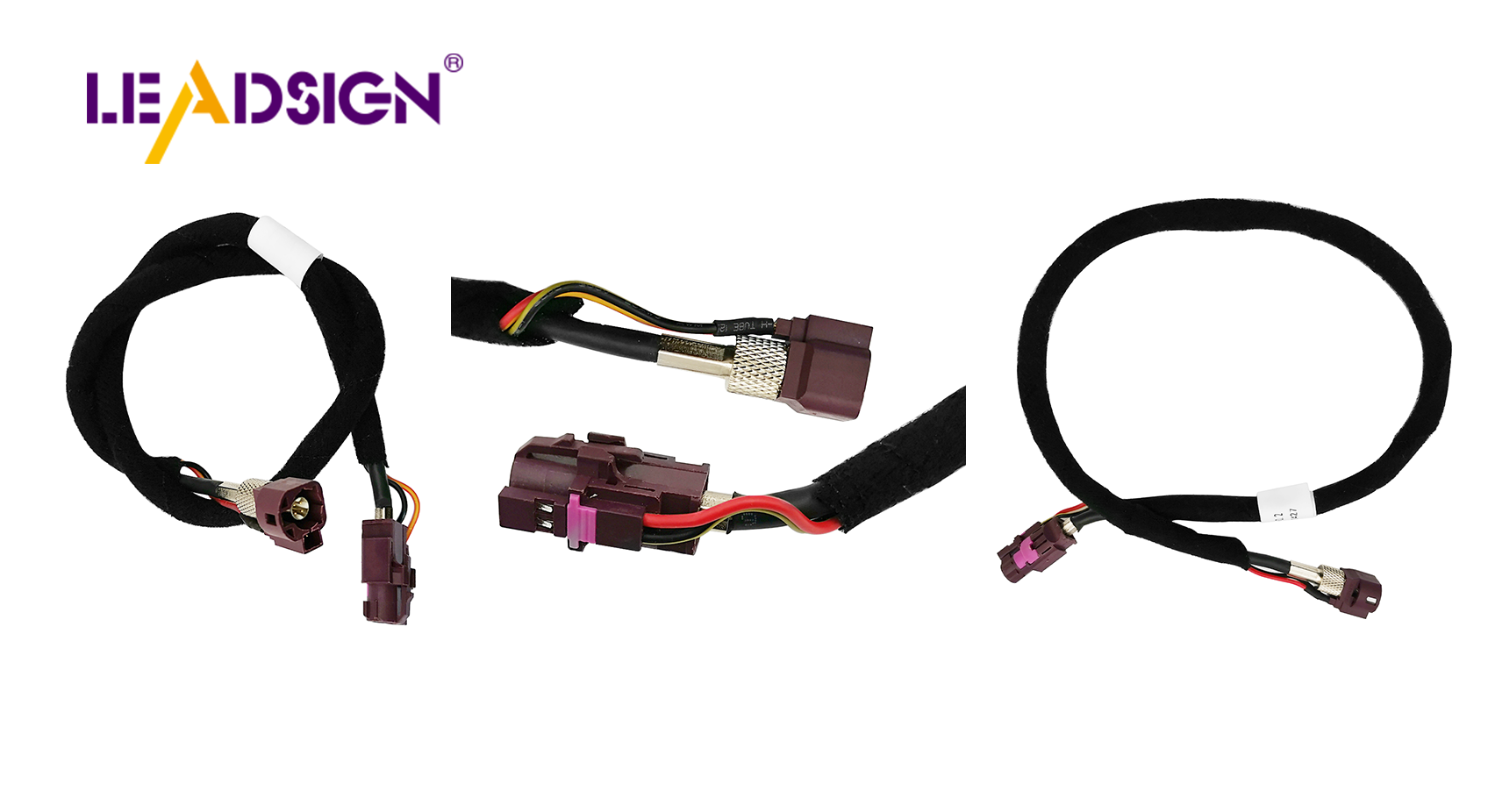

Types of Car Wire Connectors

Knowing different wire connectors is key for mechanics. Each type has a special use and benefits. Let's look at the main ones.

Crimp Connectors

Features and Benefits

Crimp connectors are common because they work well and are easy to use. They join two wires by squeezing them together tightly. This makes a strong link that keeps electricity flowing. They're tough and don't shake loose, perfect for cars.

Common Applications

Crimp connectors are in many car systems like wiring harnesses and batteries. They handle tough conditions inside or outside the car.

Solder Connectors

Features and Benefits

Solder connectors melt metal to join wires, making a solid bond. They have low resistance, so they're very reliable over time.

Common Applications

In cars, solder connectors are used where connections must last, like circuit boards and sensors.

Quick Disconnects

Features and Benefits

Quick disconnects let you easily connect or remove parts without tools. They're handy when parts need frequent changes.

Common Applications

You find quick disconnects in lights, audio gear, and more where fast access helps.

By knowing these connector types, you can choose the best one for your job. Each type offers unique advantages for car projects.

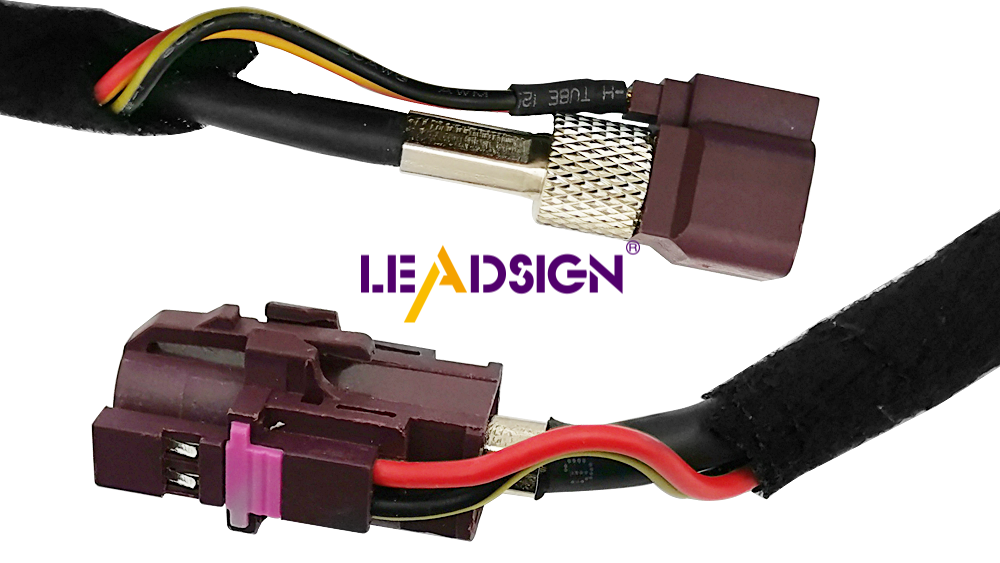

Other Important Connector Types

Deutsch and Weatherpak Connectors

Deutsch and Weatherpak connectors are very reliable. They are used in fancy construction and farm machines. These connectors keep out water and dust well. They work great in tough places. Their strong design keeps connections safe, even in hard conditions. Using these connectors makes your car projects last longer.

AMP Superseal and Delphi Metri-Pack

AMP Superseal and Delphi Metri-Pack are popular for cars. They have seals that stop water and rust. This is good where weather can hurt parts. These connectors fit tightly, so they don't come loose easily. Picking these types means strong, lasting connections for your car's electric systems.

Picking the Right Car Wire Connector

Choosing the right car wire connectors is very important. It keeps your car's electrical system safe and working well. You should think about a few things before deciding.

Things to Think About

Electrical needs

First, check what your car's electrical system needs. Different parts might need different power levels. Pick connectors that can handle the power needed without getting too hot or breaking. This helps your car's electric parts work well and last long.

Weather conditions

Next, consider where your car goes and the weather it faces. If it's often in bad weather, get connectors that block water, dust, and temperature changes. Weatherproof ones are best as they stop rust and keep connections strong.

Tips for Choosing

Matching connectors to jobs

When picking connectors, match them to what you need them for. Use crimp connectors for strong links that don't shake loose. Solder ones are good for permanent connections with low resistance. Quick disconnects are great if you often change parts.

Quality and trustworthiness

Lastly, choose quality you can trust. Get connectors made from tough materials that last long. Good quality means fewer problems later on with your car's electric system.

By thinking about these tips, you can pick the right wire connectors for your car easily. This makes sure your car runs safely and reliably.

Choosing the right wire connectors is very important. They keep your car safe and working well. Good connectors lock tightly and handle the right power levels. They should meet certain rules like ISO or SAE standards. Buying good connectors makes your car's electric system work better. It also stops problems from happening. As a mechanic, always pick quality and matching parts. This ensures strong and reliable connections in your work.

See Also

The Significance of Mini Quad Fakra Connectors in Cars

The Significance of Fakra Connectors in Honda Cars

The Significance of Fakra Car Connectors in Contemporary Vehicles