Modular Designs Redefining Automotive Harness Connectors

Car harness connectors are changing because of modular designs. These designs make cars simpler and lighter. This helps cars use less energy and be eco-friendly. Modular wiring groups tasks into zones, using shorter, thinner cables. It also makes building faster and easier with machines. This is changing how car wiring works.

Key Takeaways

Modular connectors make car wiring easier, lighter, and better. This saves energy and helps create eco-friendly cars.

These connectors make fixing and replacing parts faster and cheaper. Mechanics can replace broken parts easily without special tools.

Modular designs get cars ready for future tech like 5G. This keeps cars updated and able to use smart features.

The Problems with Old Car Harness Connectors

Hard to Design and Use

Old car harness connectors can't keep up with new car needs. As cars get smarter, wiring gets more complicated. This makes designing them slow and tricky. These old connectors use big, heavy wires. These wires make cars heavier and take up space. Handling these systems is hard and can cause problems.

Making old harness connectors takes a lot of work by hand. Workers must connect many wires carefully. This takes time, costs more money, and slows production. Over time, these problems can upset customers and lead to repairs.

Costly Repairs and Delays

Fixing old car harness connectors costs a lot and takes time. Their tricky design makes finding and fixing problems harder. When something breaks, it can take hours to fix. Big connectors make repairs worse because parts must be removed first. This raises repair costs and makes cars less reliable.

Not Fit for New Car Tech

New cars need advanced systems, but old connectors can't handle them. They can't manage fast data or precise tasks like GPS or keyless entry. Hand-assembling old harnesses often causes mistakes. These mistakes make them bad for modern cars. Old connectors don't match today's high-tech car systems.

Modular Harness Connectors: Features and Benefits

Key Features of Modular Designs

Modular harness connectors are special because of their smart design. Unlike old connectors, these use parts you can swap easily. You can take them apart or fix them without trouble. This makes repairs cheaper and faster. Instead of changing the whole connector, you just fix one part. This makes modular connectors more useful and efficient.

These connectors also use zonal wiring. This groups wires into sections, making things simpler. It also helps save space and makes cars lighter. Car makers now use these systems to make wiring easier. This change allows cars to be updated and customized easily. It also keeps cars ready for new technology.

Advantages Over Traditional Connectors

Modular connectors have many benefits over old systems. They cost less to make and fix because of their simple parts. You only need to keep a few parts in stock, saving money. If one part breaks, you can replace just that piece. This saves time and lowers repair costs.

Fixing modular connectors is quick and simple. Mechanics can find and fix problems easily without special tools. These connectors also work better with fast data and new tech. You can adjust them for different uses, making them great for modern cars.

Flexibility and Scalability for Evolving Needs

Modular connectors are flexible and can grow with new needs. You can set them up to fit your car's needs. As tech improves, you only change the old parts. This keeps your car working with the latest systems, like smart cabins.

These connectors also make fixing things easier. Mechanics can swap out broken parts quickly, saving time. Zonal wiring helps them grow by matching wires to controllers. This design works well with fast data and new tech. Modular connectors keep up with changes, helping cars stay advanced and efficient.

Trends Shaping Automotive Wiring Harness Connectors in 2025

Integration of 5G and Smart Technologies

5G and smart tech are changing how cars work. Wiring connectors now support advanced systems for better connectivity. They include sensors to check performance and find problems early. This gives real-time updates and helps prevent sudden breakdowns.

With 5G and V2X, cars share data quickly and securely. Connectors must handle fast data while keeping systems safe. These smart features also improve safety by spotting issues early. As these trends grow, cars will become smarter and more efficient.

Use of Eco-Friendly and Lightweight Materials

Car makers now use eco-friendly materials to help the planet. Connectors are made with recyclable plastics and graphene for better performance. Graphene improves energy flow and makes cars use less power.

You’ll also see plant-based and recycled materials in connectors. These materials are good for the environment and can be reused. Lightweight composites also make cars lighter, saving fuel. These changes support greener and cleaner car designs.

Thermal Management Solutions for Safety and Reliability

Managing heat is important for today’s cars. Connectors now have features to control heat and stay safe. This is especially helpful for electric and self-driving cars. Good heat control keeps parts working longer and prevents damage.

These solutions are great for high-performance systems. They keep cars running smoothly even in tough conditions. As heat management improves, cars will be safer and last longer.

Universal Connectors for Streamlined Development

Universal connectors make car design and repairs easier. They work with many systems, like USB ports for devices. You can add new features without replacing everything. This makes cars more flexible and easy to upgrade.

For you, this means faster fixes and lower costs. Universal connectors are strong and work in tough conditions. As this trend grows, cars will be easier to maintain and customize. This helps create cars that are both efficient and adaptable.

Innovations in Modular Harness Connectors

Real-World Applications in Electric and Autonomous Vehicles

Modular harness connectors are changing electric and self-driving cars. Tesla uses modular wiring to make cars simpler and lighter. For example, the Model 3 has only 1.5 kilometers of wiring. Future Tesla models may use just 100 meters of wiring. CelLink’s flat “flex harness” is another smart idea. It reduces weight by 60-75% compared to older systems. This makes electric cars lighter and better for the environment. These changes help cars perform well and support electric car growth.

Industry Adoption and Collaborative Efforts

Car companies now work together to use modular connectors. They share ideas to create systems that work worldwide. This teamwork helps modular designs spread faster in electric cars. By sharing tools, companies save money and make better cars. This means you get cars that are stronger and ready for new technology.

AI and Advanced Algorithms for Optimized Design

AI helps design better modular harness connectors. Engineers use AI to study data and plan smarter layouts. Special programs find the best wiring paths to save weight and energy. AI also spots problems early, making cars safer and more reliable. These smart designs meet the needs of today’s electric and self-driving cars.

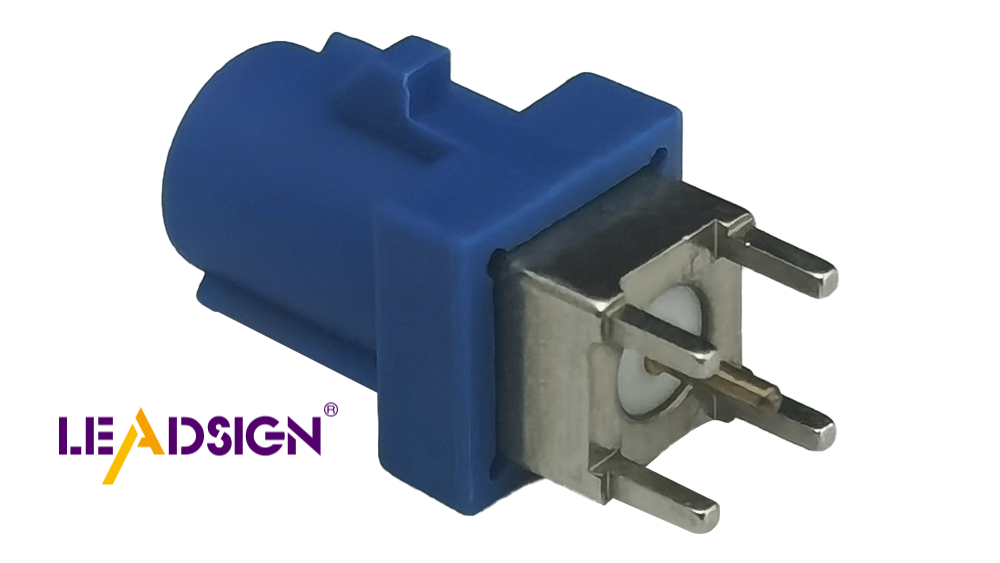

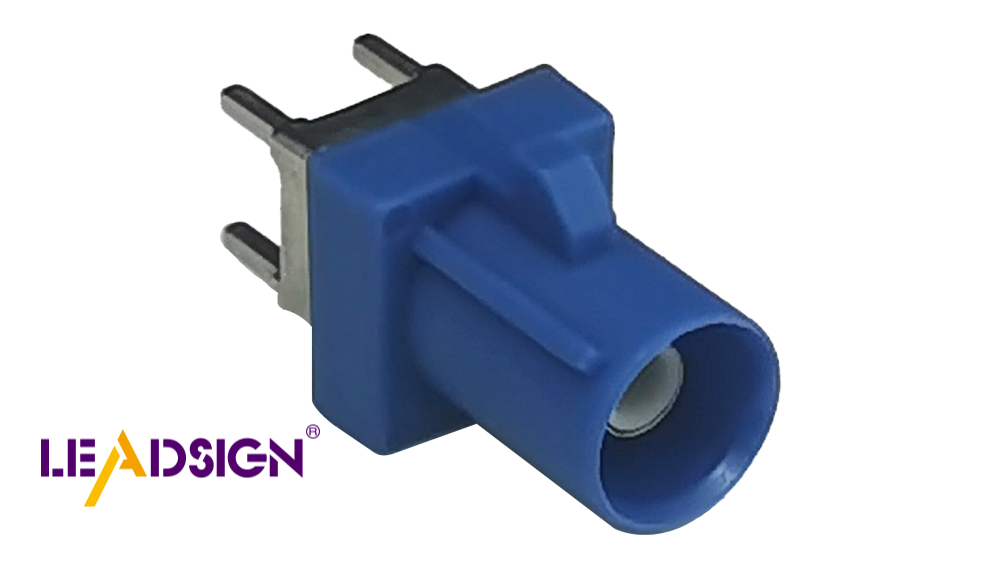

Customizable and Waterproof Solutions for Diverse Needs

Modular connectors can be changed to fit different car needs. Engineers adjust designs to match what the market wants. Standard parts lower costs and reduce extra supplies. Waterproof connectors keep out water and dirt, even in floods or rain. These features make them perfect for electric cars, staying strong in all conditions.

How Modular Designs Are Changing the Automotive Industry

Making Manufacturing Faster and Cheaper

Modular designs make car wiring easier to build. Factories use standard parts that fit many cars. This saves time and money while keeping quality high.

Standard parts speed up assembly lines.

Using the same parts for many cars lowers costs.

Broken parts can be swapped or recycled, reducing waste.

This process makes production quicker and more efficient. For you, this means cars with better wiring at a lower price.

Helping the Environment

Modular connectors support eco-friendly goals in the car industry. They use recyclable materials and create less waste. Lightweight designs help cars use less fuel or battery power.

These designs also make wiring systems smaller and simpler. This saves materials and helps make greener cars. Car makers can meet eco-goals while offering great performance.

Preparing Cars for the Future

Modular connectors get cars ready for new technology. They work with smart systems like advanced dashboards and safety tools. You’ll enjoy faster data, better connections, and safer rides.

These connectors fix problems like heavy wiring and high costs. Engineers can upgrade parts without redoing the whole system. This makes cars flexible and ready for new tech. Modular connectors also organize wiring better, making cars smarter and more modern.

Modular harness connectors fix old wiring problems and bring new ideas. They make wiring easier, cut costs, and boost car performance. Future changes will make them smaller, faster, and eco-friendly. These connectors help cars stay flexible, efficient, and ready for new tech. They are key for today’s and future car designs.

FAQ

What is a high-voltage wiring harness?

A high-voltage wiring harness links parts in electric cars. It safely moves power to systems needing high energy.

How do modular connectors affect the wiring harness market?

Modular connectors make wiring easier, cheaper, and more efficient. These improvements help the market grow quickly.

Why are modular designs important for electric vehicles?

Modular designs offer light, flexible, and green wiring options. These match electric cars' need for smart and eco-friendly tech.

See Also

Transforming Car Connectivity: Benefits of HFM Connectors

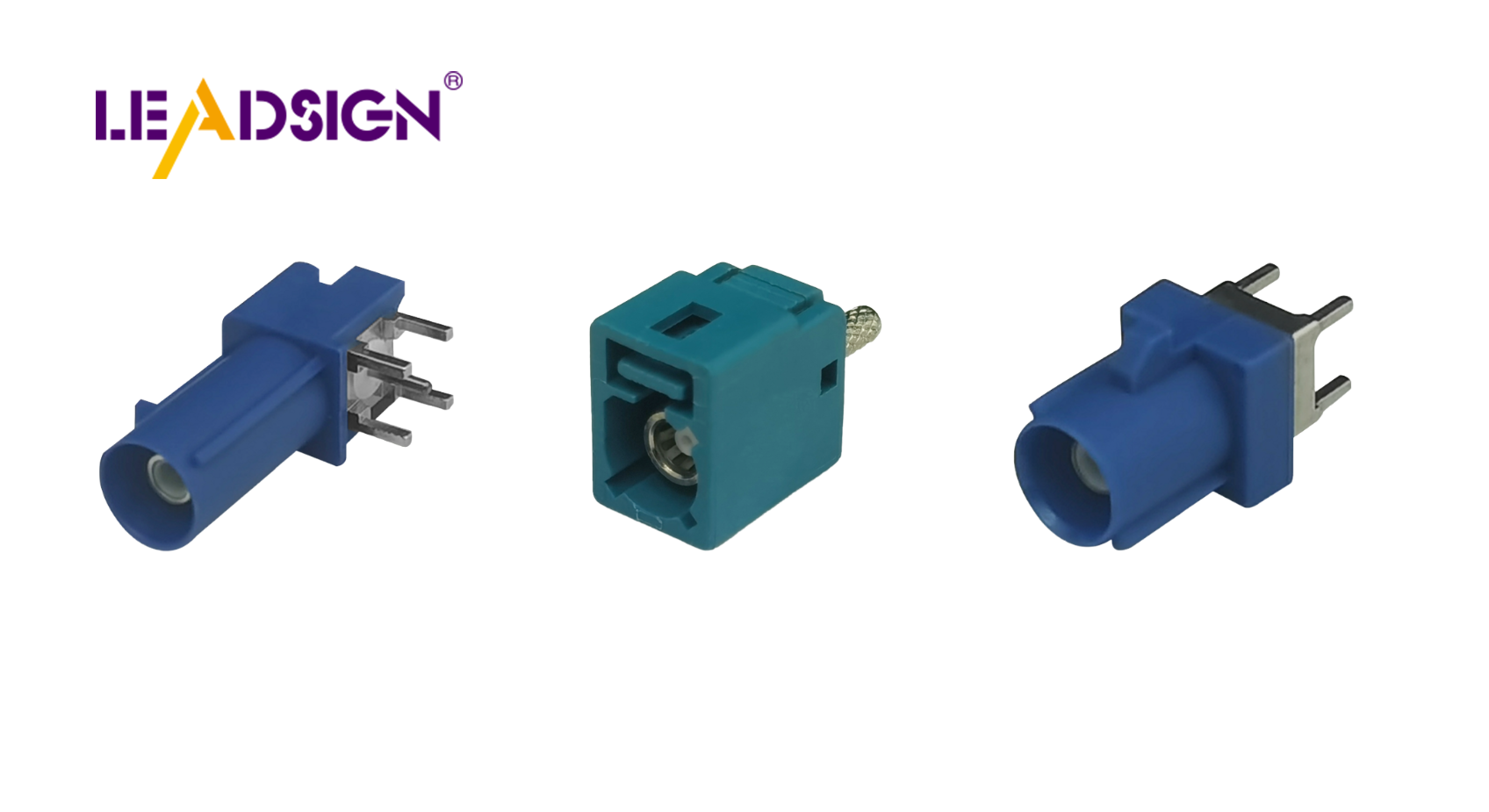

Enhancing Space Utilization: Mini FAKRA Connectors in Vehicles

Discovering Opportunities: High-Speed FAKRA-Mini Connectors for Cars

Benefits of HFM Connectors for Automotive Applications

Enhancing Vehicle Data Transfer: Innovative Connectors and Cables