Mastering Wire Connectors Types for HSD Cables

HSD cables are essential in automotive electronics, facilitating high-speed data transmission crucial for modern vehicles. These cables ensure efficient communication between various electronic components. The types of wire connectors are vital for the proper functioning of these cables, with each type serving a specific purpose to maintain connection integrity. An Ethernet cable connector, for instance, ensures reliable data transfer in automotive systems. Understanding the different types of wire connectors helps in selecting the right one for your needs.

Understanding HSD Cables

Applications of HSD Cables

Automotive Industry

HSD cables play a crucial role in automotive electronics. These cables support high-speed data transmission for systems like LVDS cameras, USB connections, and infotainment modules. Automotive manufacturers rely on HSD cables to ensure seamless communication between electronic components. The robust design of these cables withstands harsh conditions such as vibrations and temperature fluctuations.

Other Industries

HSD cables find applications beyond the automotive sector. Telecom industries use these cables in radio base stations. Digital networks benefit from the reliable data transmission capabilities of HSD cables. Industries like digital infotainment and symmetrical networks also utilize these cables for efficient connectivity.

Key Features of HSD Cables

Data Transmission Capabilities

HSD cables excel in data transmission. These cables support various protocols, including Ethernet and USB. The fully shielded design ensures minimal interference and optimal performance. High-speed data transfer becomes possible with the use of these advanced cables.

Durability and Reliability

Durability defines the construction of HSD cables. Manufacturers use strong materials to ensure longevity. These cables resist moisture, chemicals, and mechanical stress. The reliability of HSD cables reduces maintenance needs and enhances safety. OEM connectors, for example, provide consistent electrical connections, preventing faults in systems.

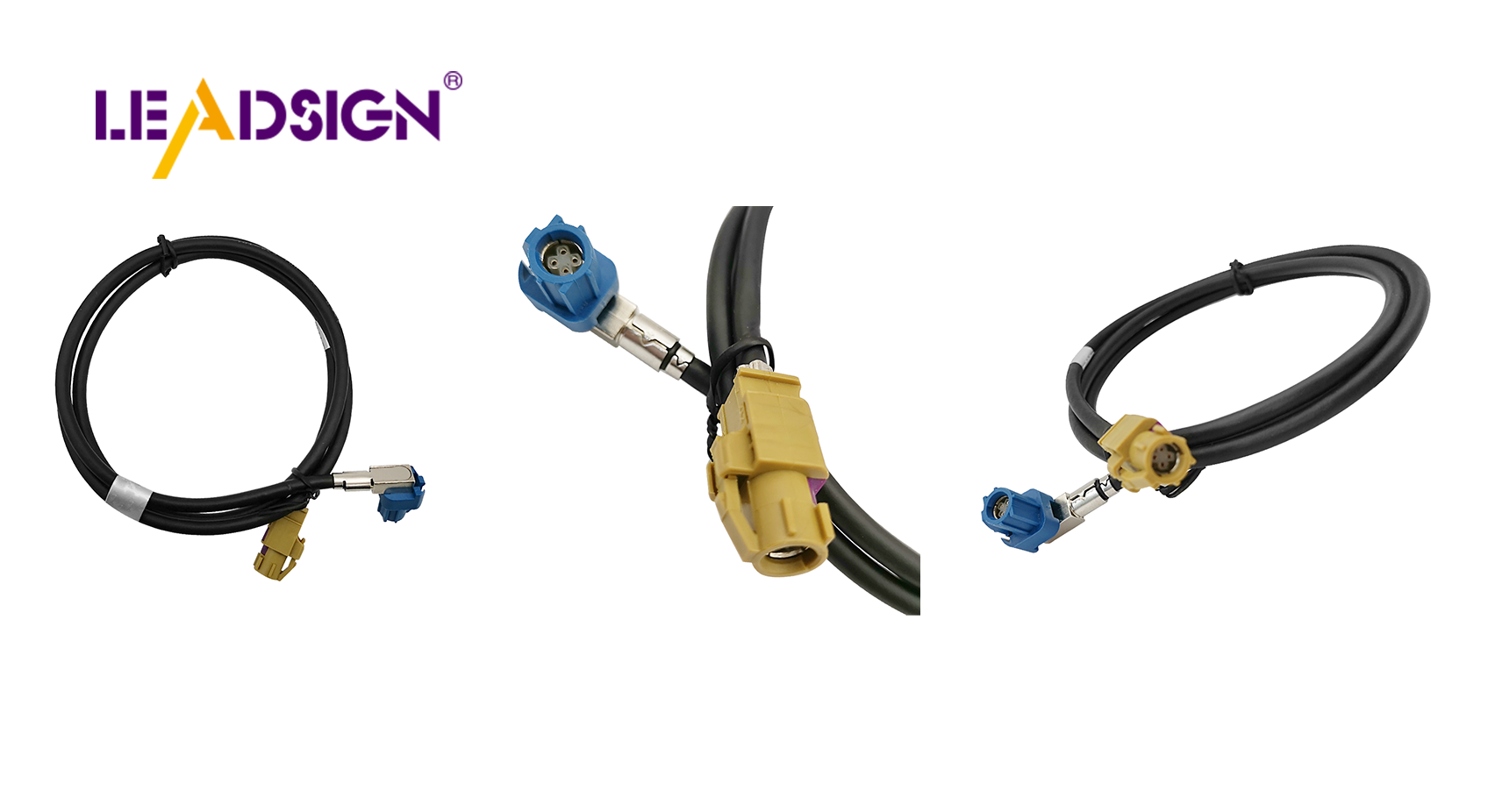

Types of Wire Connectors for HSD Cables

Understanding the different wire connectors types is crucial for ensuring optimal performance in HSD cable systems. Each type serves a specific purpose and offers unique benefits for high-speed data transmission. The right choice of connector can significantly enhance the efficiency and reliability of your automotive electronics.

Overview of Wire Connectors Types

Coaxial Connectors

Coaxial connectors are widely used in HSD cable systems due to their ability to handle high-frequency signals. These connectors provide excellent shielding against electromagnetic interference, which is essential for maintaining signal integrity. The design of coaxial connectors ensures minimal loss of data during transmission. Automotive applications often rely on these connectors for systems that require stable and high-speed data transfer.

Twisted Pair Connectors

Twisted pair connectors are another popular choice in HSD cable systems. These connectors support balanced signal transmission, reducing crosstalk and electromagnetic interference. Twisted pair connectors are compatible with various protocols, including Ethernet, making them versatile for different applications. The use of twisted pair connectors in automotive systems enhances data transmission reliability, especially in environments with high levels of electrical noise.

Features and Compatibility

Protocol Compatibility

Protocol compatibility is a critical factor when selecting wire connectors types for HSD cables. Different connectors support various communication protocols, such as USB, Ethernet, and LVDS. Choosing the right connector ensures seamless integration with existing systems. An ethernet cable connector, for example, is specifically designed to work with Ethernet standards, providing reliable data transfer in automotive networks.

Environmental Resistance

Environmental resistance is another important consideration for wire connectors types. Connectors must withstand harsh conditions, including temperature fluctuations, moisture, and chemical exposure. High-quality connectors feature robust materials and construction techniques to ensure durability. In automotive applications, connectors with strong environmental resistance reduce the risk of corrosion and mechanical failures, enhancing the overall reliability of the system.

Standards and Requirements in Automotive Electronics

Importance of Mechanical Keying

Preventing Misconnection

Mechanical keying prevents misconnections in automotive electronics. Each connector has a unique design that fits only with the correct counterpart. This feature ensures that connections are made accurately, reducing the risk of errors. Proper connections maintain the integrity of the electronic system.

Ensuring Proper Alignment

Proper alignment is crucial for effective data transmission. Mechanical keying guarantees that connectors align correctly. This alignment minimizes signal loss and enhances performance. The design of connectors with mechanical keying supports reliable communication between components.

Role of Latching Mechanisms

Securing Connections

Latching mechanisms secure connections in automotive systems. These mechanisms lock connectors in place, preventing accidental disconnections. Secure connections are vital for maintaining continuous data flow. The use of latching mechanisms enhances the stability of the electronic network.

Enhancing Safety

Safety is a priority in automotive electronics. Latching mechanisms contribute to safety by ensuring that connections remain intact. A secure connection reduces the risk of electrical faults. The reliability provided by latching mechanisms protects both the vehicle and its occupants.

Significance of Color Coding

Easy Identification

Color coding simplifies the identification of connectors. Each color represents a specific function or protocol. This visual aid helps technicians quickly identify the correct connectors. Easy identification speeds up the installation and maintenance processes.

Reducing Errors

Errors can occur during the connection process. Color coding reduces these errors by providing clear visual cues. Technicians can easily match connectors based on color. This method minimizes the chance of incorrect connections, improving overall system reliability.

Selecting the Right Connectors

Factors to Consider

Application Requirements

Selecting the right connectors for HSD cables requires understanding specific application requirements. Each application has unique demands that influence the choice of connectors. High-speed data transmission applications need connectors that support the required protocols. Automotive systems often require connectors that handle Ethernet, USB, or LVDS protocols. The right connector ensures efficient communication between components.

Environmental Conditions

Environmental conditions play a crucial role in choosing connectors. Harsh environments demand connectors with robust construction. Temperature fluctuations, moisture, and chemical exposure can affect connector performance. High-quality connectors resist these conditions, ensuring durability and reliability. Automotive applications often face challenging environments. Choosing connectors with strong environmental resistance enhances system longevity.

Practical Advice

Consulting Industry Standards

Consulting industry standards provides valuable guidance in selecting connectors. Standards ensure compatibility and reliability across different systems. Industry standards outline specifications for various connector types. Following these standards helps in making informed decisions. Adhering to standards ensures that connectors meet the required performance criteria.

Seeking Expert Guidance

Seeking expert guidance offers insights into the best connector choices. Experts in automotive electrical wiring connectors provide valuable advice. Experts understand the nuances of different applications and environmental challenges. Consulting experts helps in selecting connectors that meet specific needs. Expert advice ensures that connectors enhance system performance and reliability.

Understanding wire connectors for HSD cables is crucial for ensuring optimal performance in automotive electronics. Making informed decisions when selecting connectors enhances system reliability and efficiency. Consider factors like protocol compatibility and environmental resistance. Stay updated with industry advancements to keep pace with evolving technologies. OEM connectors offer long-lasting solutions due to their rigorous testing and engineering standards. These connectors meet or exceed performance requirements, providing a reliable choice for your needs. Embrace the latest developments to maintain a competitive edge in automotive electronics.

See Also

An Extensive Overview of HSD Connectors

Fundamentals of HSD Connectors in Auto Sector

The Significance of HSD Connectors in Auto Sector