Mastering Car Wire Connector Types for Optimal Performance

Understanding wire connectors automotive type is crucial for enhancing vehicle performance. These connectors are essential to your car's electrical system, facilitating seamless communication between components. By familiarizing yourself with different wire connectors automotive type, you can improve your car's efficiency and longevity. There are various types of connectors available, each designed for specific functions such as conducting electricity, resisting corrosion, and withstanding heat. As cars become more complex, especially with electric and hybrid models, selecting the right connector is vital.

Understanding Car Wire Connectors

What are Car Wire Connectors?

Definition and Purpose

Car wire connectors are important for your car's electrical system. They link wires so electricity can move easily between parts. This helps things like headlights and radios work well. Knowing about these connectors helps keep your car running smoothly and avoids electrical problems.

Common Materials Used

Different materials make up car wire connectors. Each has special features for certain uses. Common ones include:

Plastic: Keeps wires dry and safe.

Metal: Lets electricity pass well and lasts long.

Ceramic: Handles high heat and doesn't rust.

Picking the right material depends on how it conducts electricity, fights rust, and handles heat. Choosing wisely makes your car's electrical system last longer and work better.

How Connectors Affect Performance

Electrical Efficiency

Your car's electrical system works best with good connectors. Good ones let electricity flow easily with little resistance. This saves energy and boosts your car's performance. Using good connectors can help save fuel and cut down pollution.

Durability and Reliability

Strong, reliable connectors keep your car working well. They must handle tough conditions like shaking, heat, and wetness. Strong connectors stop electric failures, keeping everything working right. Reliable ones also lower the chance of short circuits, making sure your car stays safe to use.

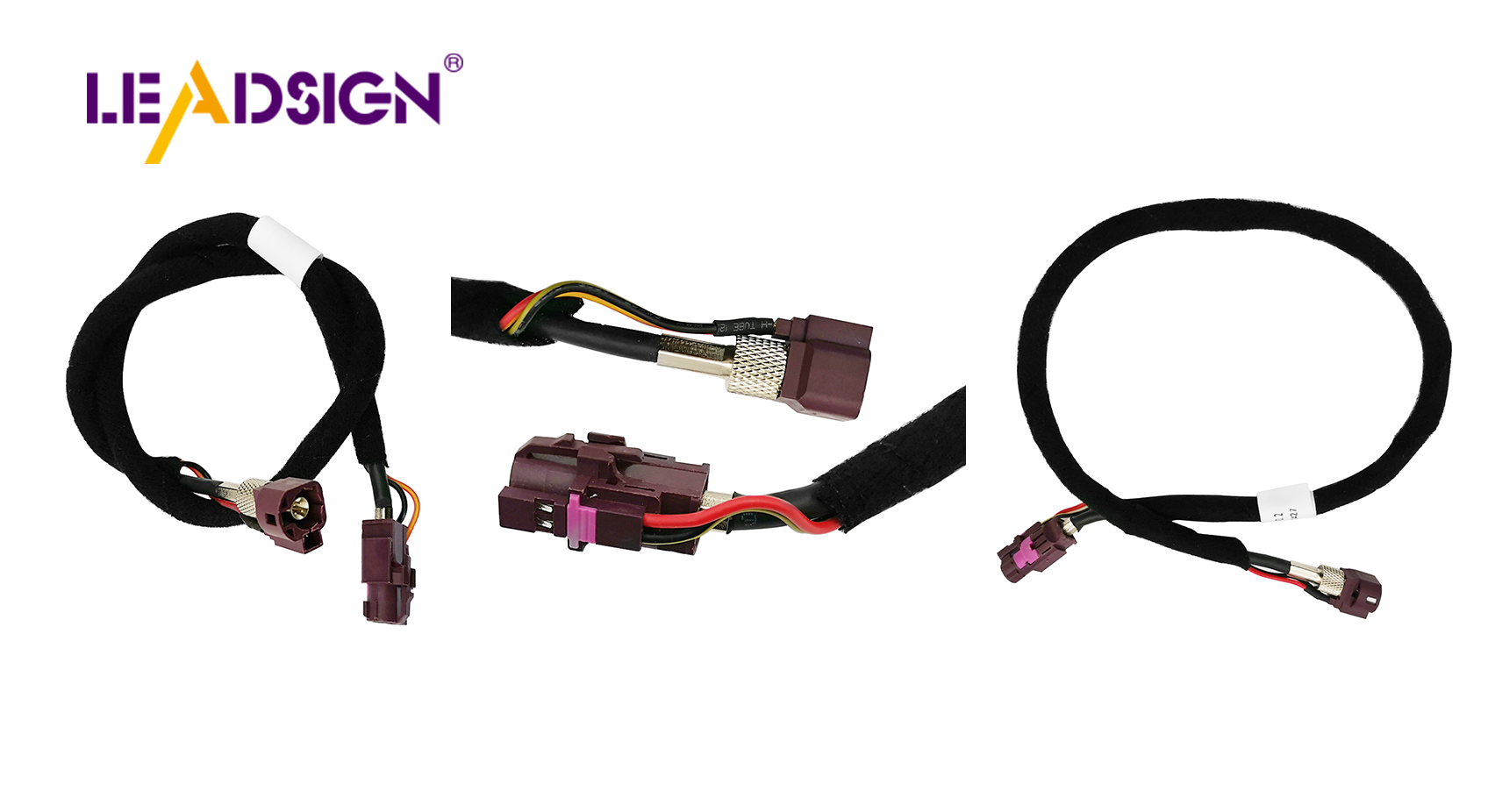

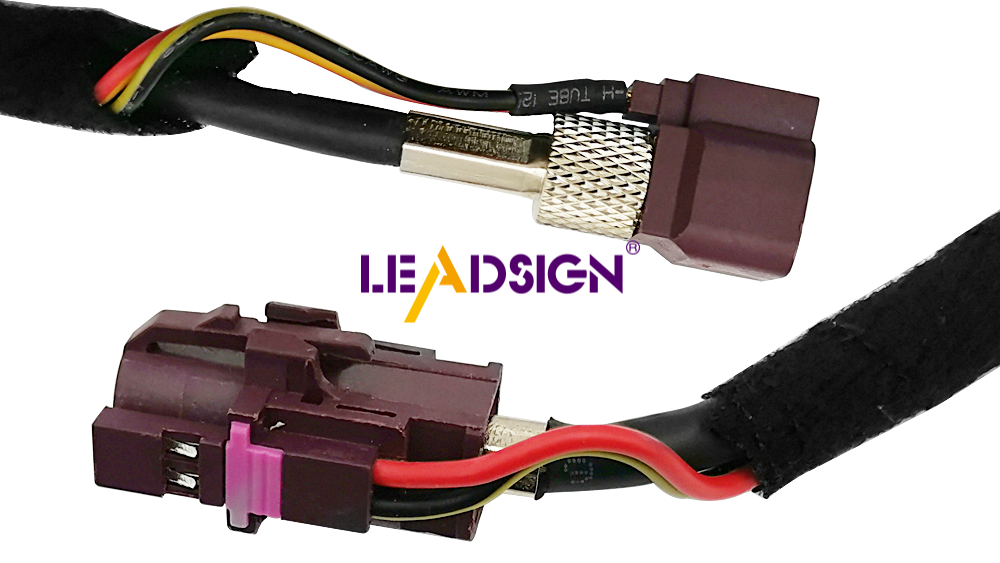

Exploring Wire Connectors Automotive Type

Knowing different wire connectors helps pick the best for your car. Each type has special uses and features. Let's look at some common ones in cars.

Blade Connectors

Features and Applications

Blade connectors are flat metal pieces that fit into slots. They're found in fuse boxes and panels. They connect well and are easy to use. They’re great when you need to unplug often.

Pros and Cons

Pros:

Easy to use

Stay connected well

Cheap and easy to find

Cons:

Only for low power

Can rust if wet

Butt Connectors

Features and Applications

Butt connectors join two wires together. They're used to fix or extend wires in cars. They crimp wires tightly, so they’re good for lasting setups.

Pros and Cons

Pros:

Strong connection

Easy to set up

Fit different wire sizes

Cons:

Hard to undo once set

Need a tool to crimp

Ring and Spade Connectors

Features and Applications

Ring and spade connectors link wires to screws or blocks. Rings make a full circle; spades have an open end for quick changes. Used in battery links.

Pros and Cons

Pros:

Secure with little risk of coming loose

Simple to attach

Good for high power needs

Cons:

Need tools for setup

Rings need screw removal to undo

By learning about these types, you can choose wisely for your car's needs. Each has its own pros and cons, so think about what you need for best results.

Quick Disconnects

Quick disconnects make it easy to connect and unconnect wires in cars. They are often used in car systems because they don't need special tools. These connectors are handy when you have to connect and unconnect parts a lot, like during repairs.

Features and Applications

Quick disconnects have features that suit many car uses:

Ease of Use: You can quickly attach or remove wires. This is great when you need to work fast.

Versatility: Use them on either end of a wire, making your setup flexible.

Durability: Built tough for car conditions, these connectors last long.

They are used where wires need frequent changes, like lights and audio gear. They help parts talk well and save energy, making them useful for any car system.

Pros and Cons

Think about the good and bad of quick disconnects:

Pros:

Convenience: Manage connections easily without tools, saving time.

Flexibility: Fit different needs with various wire connectors automotive type.

Reliability: Keep signals strong and power steady.

Cons:

Limited Use: Not always right for very powerful tasks.

Potential Wear: Lots of use can wear them out over time.

Knowing about quick disconnects helps you choose wisely for your car. Whether fixing things or boosting your electrical system, they offer a smart solution.

Picking the Best Connector for Your Car

Choosing the right wire connector is key for your car. Think about a few things to make sure it works well and lasts long.

Things to Think About

Power Needs

First, check your car's power needs. Different connectors handle different amounts of electricity. Pick ones that can handle your car’s power. This keeps energy flowing well and stops overheating.

Weather Conditions

Next, consider the weather where you drive. If it's humid or very hot, choose connectors that resist rust and heat. This keeps your car's electric system safe and working well.

Quality vs. Cost

Why Quality Matters

Quality is important when picking connectors. Good ones conduct electricity better and last longer. They lower the risk of problems and keep your car safe. Spending on quality helps in the long run.

Balancing Money and Performance

While quality matters, think about cost too. Find connectors that work well within your budget. Sometimes paying more saves money later by cutting repair costs.

By thinking about these points, you can pick the best wire connectors for your car’s needs. This choice makes your car run better and last longer.

Practical Tips for Installation and Maintenance

Installing and taking care of car wire connectors keeps your vehicle's electric system working well. By doing things right, you can stop problems and make connectors last longer.

Installation Best Practices

Tools Needed

To put in wire connectors properly, get these tools:

Wire Strippers: To take off the plastic cover from wires.

Crimping Tool: For attaching connectors to wires tightly.

Screwdriver: Handy for ring and spade connectors.

Heat Gun: Used for heat-shrink tubing to add protection.

Having these tools ready makes installing easier and faster.

Easy Steps to Follow

Get Wires Ready: Use wire strippers to take off about half an inch of the wire cover. Make sure the bare wire is clean and not broken.

Pick a Connector: Choose the right connector type for your car’s needs. Think about how much electricity it uses and where it will be used.

Connect It Right: Put the bare wire into the connector. Use a crimping tool to hold it tight. Make sure it's snug so there are no electric problems.

Protect the Connection: If using heat-shrink tubing, slide it over and use a heat gun on it. This step helps keep out water and stops rust.

Check Your Work: After putting everything together, test it to see if it works well. Look for loose wires or bad connections.

Maintenance Tips

Check Regularly

Look at your wire connectors often to keep them working well. Watch out for wear, rust, or damage, especially in tough spots like hot or wet places. Finding problems early stops bigger issues later.

Fixing Common Problems

If you have trouble with connectors, try these fixes:

Tighten Loose Connections: Make sure all parts are held tight together because loose ones can cause electric failures.

Look for Rust: Rust can block electricity flow. Clean rusty spots with cleaner and protect them with special grease.

Swap Bad Connectors: If a connector is very worn or broken, change it quickly. Using bad ones can hurt your car’s safety and performance.

By following these tips on installation and maintenance, you help keep your car's electric system strong and efficient. Taking good care of wire connectors automotive type boosts your car's overall performance and life span.

Understanding car wire connectors is important for your car's performance. Each type helps make sure electrical connections work well and are safe. Picking the right connectors makes your car run better and safer.

"It's very important to have safe and reliable electrical connections for key car parts."

Learn more to know better or talk to experts for good choices. Your car's life and how well it works rely on this.

See Also

Boosting Automotive Efficiency with HFM Connectors

Maximizing Data Transfer in Automotive: Advanced Connectors

Fundamentals of HSD Connectors in Automotive Sector

Uncovering Advantages of Fakra Auto Connectors

Improving Data Transfer: Significance of High-Speed Auto Connectors