Mastering Car Wire Connector Types for Easy Replacement

Knowing different car wire connector types is crucial in today's automotive industry. Cars rely on various connectors to facilitate communication between different components. Understanding these connectors offers several advantages:

Efficiency: Quickly identify and replace faulty connectors, saving time.

Cost-effectiveness: Prevent unnecessary repairs by promptly addressing connector issues.

Safety: Maintain secure connections to prevent electrical issues.

This knowledge enables you to effectively maintain your car's electrical system, enhancing its performance and longevity.

Identifying Car Wire Connector Types

Knowing car wire connectors is important for fixing cars. This part will teach you how to spot these connectors by looking at their shapes and details.

Basic Identification

Plug vs. Receptacle

To tell car wire connectors apart, first know plugs from receptacles. A plug has pins that go into a receptacle with sockets. Knowing this helps you see how they connect in a car.

Common Connector Types

Many connector types are used in cars. Crimp connectors are liked because they are easy to use. You put the wire end in and crimp it tight without soldering. Other types like butt and solder connectors have special uses too.

Visual Characteristics

Shape and Size

Car wire connectors come in different shapes and sizes. Some are round, others square or rectangle. The size changes based on what it's for. Noticing these helps pick the right one to replace.

Color Coding

Color coding is key to spotting connectors. Different colors show what they do or the wire size. Watching these colors makes picking the right connector easier.

Pin Count

The number of pins shows which connector it is. Count them to match with its pair, making sure it works right in the car.

Specific Details

Keyways and Locking Mechanisms

Keyways make sure connections fit only one way, stopping wrong fits. Locks keep them tight even when cars shake a lot.

Connector Location in Vehicles

Knowing where connectors are in a car helps find them fast. They can be under the hood, dashboard, or underneath the car.

Tools and Resources for Identification

It's easier to know car wire connector types with the right tools. These tools help you pick the correct connector.

Wiring Diagrams

Wiring diagrams are key to spotting car wire connector types. They show how your car's electrical parts connect.

How to Read Wiring Diagrams

Start by learning symbols and lines in diagrams. Symbols stand for parts, and lines show connections. Look at colors and labels; they tell wire type and job. By knowing this, you can follow electric paths and find connectors.

Sources for Obtaining Diagrams

You can get wiring diagrams from:

Vehicle Manuals: Car manuals have model-specific diagrams.

Online Databases: Sites like AutoZone give many diagrams.

Automotive Repair Shops: Some shops let you see their diagram collection.

These sources help you find the right car wire connector types.

Online Tools and Databases

Online tools give lots of info on car wire connector types. They show pictures, making it easy to match connectors.

Recommended Online Resources

Some online resources help spot connectors:

Connector Suppliers: Maker websites have detailed catalogs.

Automotive Forums: Places like Reddit's r/MechanicAdvice offer user tips.

YouTube Tutorials: Videos guide you on finding and changing connectors.

These resources boost your knowledge of connectors and uses.

How to Use Online Tools Effectively

To use online tools well, do this:

Search for Specific Connectors: Use search to find needed connectors.

Compare Images and Descriptions: Match images with your connector.

Read User Reviews and Comments: Learn from others' experiences with these connectors.

Using these tools helps you change car wire connectors right, keeping your car's electric system working well.

Step-by-Step Replacement Process

Changing car wire connectors needs careful work. Follow these steps for success.

Preparation

Gathering Necessary Tools

First, get all the tools you need. You will need pliers, a wire stripper, and a multimeter. These tools help with connectors safely and quickly. Having them ready means no delays in your work.

Safety Precautions

Safety is important with electrical parts. Always unplug the car battery first. This stops shocks or short circuits from happening. Wear gloves to keep safe from sharp or hot things. These steps keep you and your car safe.

Removal of Old Connectors

Disconnecting Safely

To take out old connectors, know what type they are. Use a tool to unlock connector locks easily. Gently pull apart without harming wires. Doing this right avoids more problems and gets ready for new ones.

Handling Damaged Connectors

Look at old connectors for cracks or rust spots. Bad connectors can cause electric issues. If damaged, change it right away. This keeps your car's electric system working well.

Installation of New Connectors

Ensuring Proper Fit

When putting in new connectors, make sure they fit right. Match shape, size, and pin number with the old one. A good fit stops loose connections and keeps things secure.

Testing the Connection

After putting in new ones, test them with a multimeter. Check that electricity flows without stopping. Testing shows if the connector works well and if everything runs smoothly.

By doing these steps, you can change car wire connectors easily, making your car better and last longer.

Learning about car wire connectors is important for fixing cars easily. By knowing their shapes, sizes, and pin numbers, you can find and change them fast. Use wiring diagrams and online tools to learn more. Ask for help from forums or watch tutorials if needed. As you practice, working with car wire connectors will become easy. This knowledge saves time and money and keeps your car safe and lasting longer. Enjoy learning about car wire connectors and see the benefits it brings.

See Also

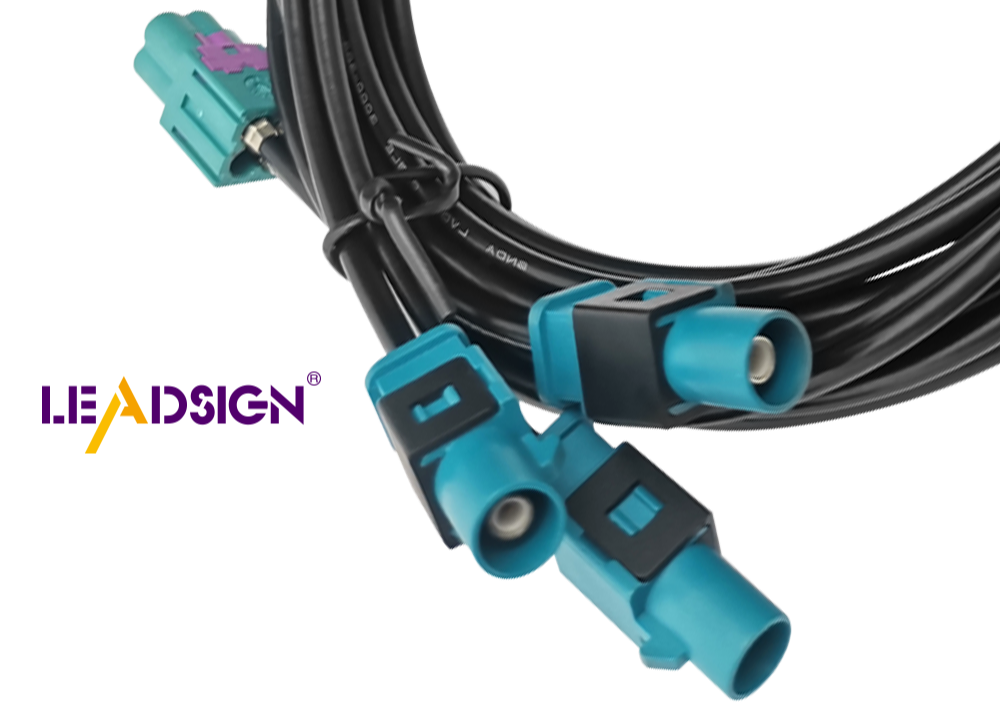

Navigating Ford Fakra Connectors: A Comprehensive Overview

Essential HSD Connectors in Automotive Technology

Harnessing Mini Fakra Connectors for Automotive Innovation