Mastering Car Wire Connector Types Installation Techniques

Installing automotive wiring connectors in your car is crucial for maintaining safety and reliability. Understanding the various automotive wiring connector types can help prevent loose wires and electrical issues. Familiarizing yourself with these connectors can save you time and money while enhancing your confidence in repairing car electronics. Developing the ability to identify and resolve issues promptly contributes to improved car performance and longevity. Begin acquiring these skills today to ensure a well-maintained vehicle.

Understanding Car Wiring Connectors

When fixing your car's wires, it's important to know about different connectors. These help parts of your car talk to each other. Let's look at some common ones.

Common Car Wiring Connectors

Bullet Connectors

Bullet connectors are small and round. They snap together easily. You see them often in cars because they are simple to use. They connect low-power wires well. Make sure they fit tightly so they don't come loose.

Butt Connectors

Butt connectors join two wire ends together. They are great for making wires longer or fixing broken parts. Strip the wire ends, put them in the connector, and crimp tight. This keeps the connection strong.

Spade Connectors

Spade connectors look like forks, which makes them easy to attach and remove. Use them when you need to take wires on and off a lot. Make sure the spade fits well for a good connection.

Picking the Right Connector

Choosing the right connector is very important for your work.

Things to Think About

Think about where you'll use the connector. Is it wet or hot there? Pick ones that can handle these conditions. Also, check how much power goes through it. The wrong one can break or be dangerous.

Fit with Your Car

Make sure connectors match your car's system. Check details and read your car manual if needed. Wrong connectors can mess up or harm your car's electronics. Always double-check to avoid mistakes.

By knowing these wiring connectors, you can fix your car's wires confidently. Whether fixing or upgrading, picking the right connector is key.

Tools and Materials Needed

When starting with car wire connectors, having the right tools is key. Let's see what you need for an easy installation.

Important Tools for Installation

To work with car wires, you'll need some basic tools. These help you handle wires safely.

Wire Strippers

Wire strippers are great for dealing with wires. They remove the plastic cover without hurting the wire. Just put the wire in, squeeze, and pull. This tool makes sure your wire ends are clean.

Crimping Tools

Crimping tools attach connectors to wires tightly. They make sure the connection is strong. Put the connector and wire in, squeeze, and it’s done. A good crimping tool keeps your connectors secure.

Heat Guns

Heat guns help seal connections well. After crimping, use heat shrink tubing to protect it. The heat gun shrinks the tubing around it, adding protection from water and wear.

Needed Materials

Besides tools, you'll need materials for car wiring connector installation.

Wire Connectors

Wire connectors are very important. They come in different shapes like bullet or spade types. Each type does a different job, so pick wisely. Having many types ready helps with any wiring task.

Heat Shrink Tubing

Heat shrink tubing protects your connections after crimping. Slide it over and use your heat gun to shrink it tight. This step keeps your connections safe from water and harm.

By getting these tools and materials ready, you're set for success. With them, you can install car wire connectors confidently. Remember, being prepared leads to a job well done.

Step-by-Step Installation Techniques

Learning how to install car wire connectors takes a few steps. Let's go through them to make sure you do it right every time.

Preparing the Wires

Before connecting, prepare the wires well. This is important for a strong connection.

Stripping the Wire Insulation

First, use your wire strippers. Take off just enough plastic to show the wire without hurting it. Put the wire in the tool, squeeze gently, and pull off the cover. Now you can see clean wire ready to connect.

Ensuring Clean and Secure Connections

After stripping, look at the wire ends. They should not have any loose strands. Twist the bare wire so it's neat and tight. This helps when you attach a connector because it holds better. A clean connection means electricity flows well and fewer problems later.

Connecting the Wires

Now that wires are ready, let's connect them using good methods.

Crimping Techniques

Crimping is a common way to join wires with connectors. Put the bare wire into a connector. Use your crimping tool to press tightly around it. This makes a strong hold that keeps wires in place. Make sure it's tight so wires don't slip out.

Soldering Methods

For lasting connections, try soldering. Heat up your soldering iron and touch it where wire meets connector. Add some solder for a solid link. This gives great flow of electricity and lasts long too. Be careful not to get wires too hot or they might break.

Securing and Testing the Connection

With wires joined, next step is securing and testing them.

Applying Heat Shrink Tubing

Slide heat shrink tubing over where they join together. Use your heat gun until tubing fits snugly on both parts. This keeps water out and protects from wear making it last longer.

Testing for Electrical Continuity

Finally check if electricity passes through well with a multimeter test tool . If numbers look good then job done right! It shows car’s wiring works fine now after installing these connectors properly .

By following these steps ,you’ll confidently set up car wiring connections . Each part ensures reliable links keeping electronics working smoothly .

You've learned how to install car wire connectors. Practice helps you get better. The more you use these connectors, the easier it gets. Doing it right keeps your car safe and working well. Take your time and follow each step carefully. Soon, you'll be great at using car wire connectors. Keep practicing, and your car will run better for longer.

See Also

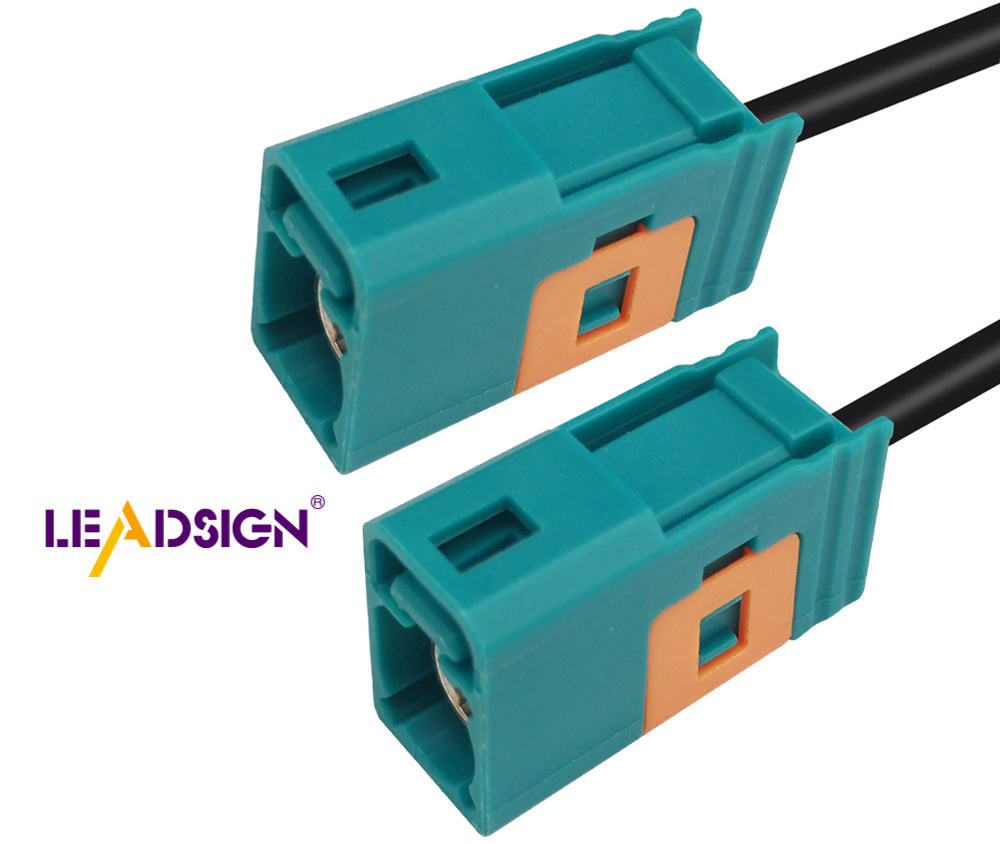

Exploring HSD Connectors in Automotive Technology

In-Depth Look at Fakra Male Connectors

Navigating Ford Fakra Connectors

Complete Overview of HSD Connectors

All About Fakra Connectors: Fundamentals, Varieties, and Uses