Mastering Automotive Wire Integration for Enhanced Vehicle Electronics

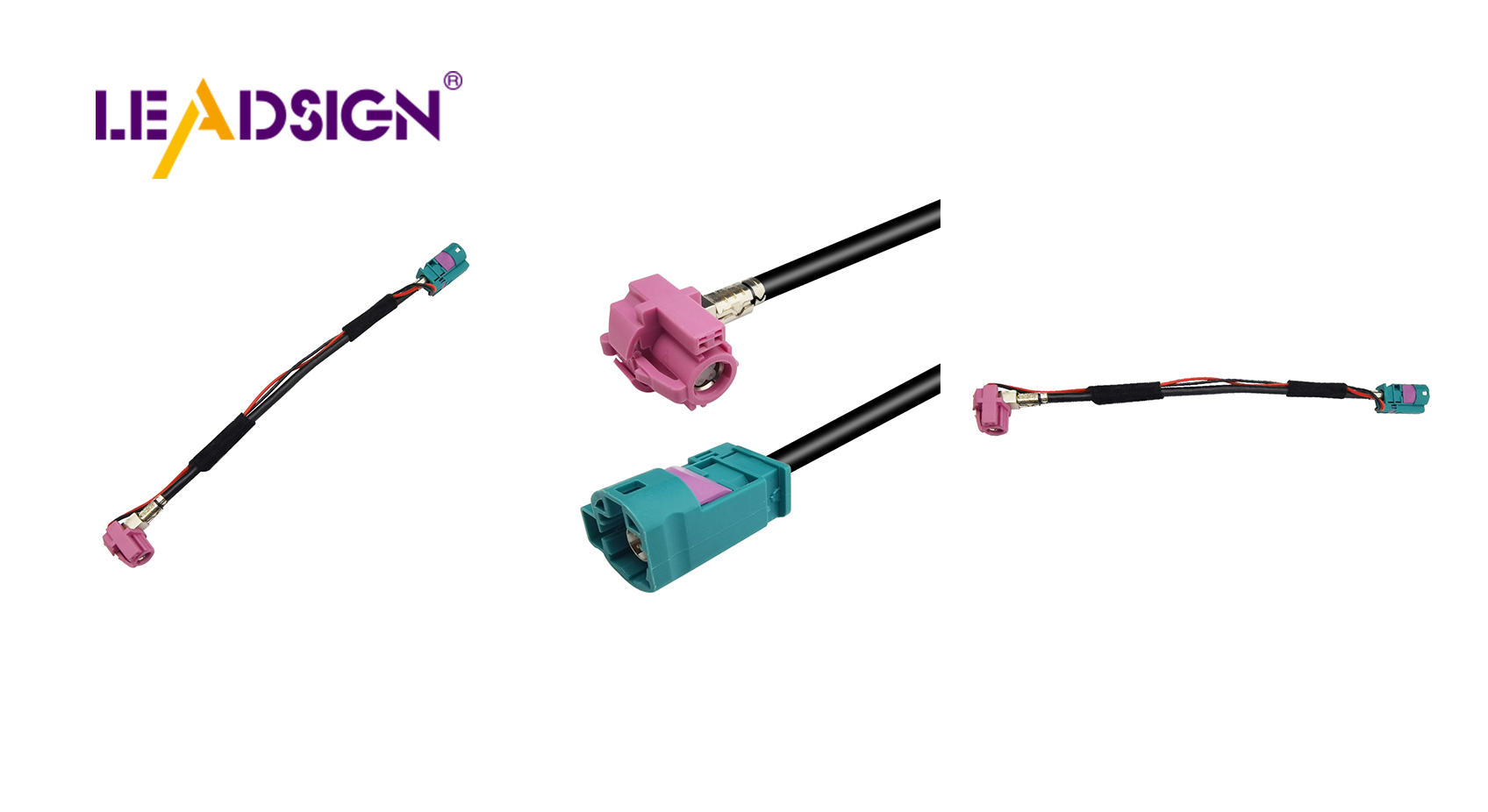

In modern vehicles, the integration of automotive wire is crucial for seamless communication between various systems. Automotive electronics rely on high-quality wiring to function optimally, and the HSD Cable plays a vital role in this process. This cable enhances connectivity and performance with features such as mechanical keying and secure latching, ensuring robust connections within automotive electronics. The HSD Cable complies with global standards for reliability and efficiency. As automakers seek superior wiring solutions, this drives innovation and technological advancements in the industry.

Basics of Car Wire Bundles

Job of Wire Bundles

Car wire bundles are like the body's nerves. They link different car parts to share power and messages. These wires help car electronics work well.

Importance in Car Electronics

Wire bundles help car gadgets talk easily. Wires are set up so each part gets signals it needs. This setup makes cars work better and last longer.

Parts and Build

A wire bundle has many parts like plugs, ends, and covers. Each part helps keep the bundle strong and working well. The design keeps wires safe from weather, stopping harm.

Role in Today's Cars

Wire bundles matter a lot in new cars for good working and safety. New tech in cars depends on these bundles doing their job right.

Working Well and Trustworthy

Good wire bundles make sure cars run smoothly. Strong links stop electric problems that cost money to fix. Makers focus on top-quality bundles for best car performance.

Safety Points

Safety in wire bundle design cuts down electric risks. Good covers and tight links lower short circuit chances. Car wires must be super safe to protect cars and people inside.

Mechanical Keying and Latching

Mechanical keying and latching are important for HSD Cables. They keep connections tight when cars move. This stops wires from coming loose, which can break data flow. The keying design makes sure connectors fit right, avoiding mistakes. This helps the car's electronics work well.

Keeping Connections Safe

Safe connections in HSD Cables mean parts talk without stopping. Strong latches hold connectors steady even with shaking or bumps. Engineers make sure connections stay safe to keep systems working great.

Following World Rules

HSD Cables follow strict world rules for cars. These rules help cables fit many car types everywhere. Makers follow these guides to make cables that work well worldwide. Meeting these rules makes HSD Cables trusted and reliable.

Color Coding and Identification

Color coding makes setting up HSD Cables easy. Each cable has a different color to spot quickly. Installers see colors fast, saving time during setup. Clear colors cut down mistakes, making sure wires connect right.

Making Setup Easy

Easy setups use color-coded HSD Cables. Installers match colors to connect wires correctly. This way is less tricky and faster for wiring jobs. Quick setup helps make cars faster in factories.

Better Maintenance

Good maintenance uses color-coded HSD Cables for easy checks or fixes. Technicians find cables fast during routine work or repairs. Quick finding speeds up fixing, keeping car downtime low. Good maintenance keeps car electronics running their best.

Uses of HSD Cables in Car Electronics

LVDS Cameras

Clear Video Sending

LVDS cameras use HSD cables for clear video. These cables help send fast data for sharp pictures. This helps car systems see better, like driver aids. HSD cables keep signals strong for good video. Engineers make them fit new camera needs.

Joining with Car Systems

HSD cables link LVDS cameras to car parts easily. They connect cameras to screens and controls well. Cars need strong links for best work. HSD cables give enough speed for live video. This helps with lane warnings and parking help.

USB and Ethernet

Moving Data Fast

Cars use HSD cables for USB and Ethernet data moves. These cables let devices talk quickly in cars. Good data flow is key for music and maps in cars. HSD cables stop data loss, keeping systems steady. Their tough build handles car wear.

Many Uses

HSD cables work in many car jobs. USB and Ethernet links use these flexible cables. Car systems need changeable setups often. HSD cables fit many needs, like fun or fixing tools. They work with lots of standards, making them useful in cars.

Challenges in Wire Integration

Matching Wires and Connectors

Car wire integration has problems when matching wires with connectors. Different designs cause fit issues. Engineers must make sure wires fit right. Wrong matches can cause bad performance or system problems.

Fit Problems

Fit problems happen when wires and connectors don't match. Different makers use different standards. This mismatch messes up car electronics. Wrong parts can cause signal loss or electric trouble.

Fixes and New Ideas

New ideas help fix fit problems. Engineers make universal connectors for many wire types. Standard rules help stop mismatches. Better materials make them strong and bendy. These fixes make car wire systems better.

Smart Software Tools

Smart software tools are key in wire integration. Automation makes the process easier. Engineers use software to draw wiring plans exactly right. These tools help make production accurate and fast.

Automating the Process

Automation cuts down mistakes in wire work. Programs do repeat tasks automatically. Engineers trust these tools for steady results. Automated systems speed up building time, saving money and boosting quality.

Boosting Accuracy and Speed

Accuracy in wiring helps cars work best. Software boosts accuracy with detailed plans. Engineers get it right using digital tests first. Fast processes cut waste, making more products quickly. These changes help the car industry a lot.

Car wire integration is key for future car electronics. More people want new and smart solutions. Engineers work on making systems that are good and reliable. New tech like sensors and data help design better wires. These changes make cars safer and work better. Car makers focus on adding the latest features to cars. The car world keeps changing with these new ideas. Wire integration is very important in this change. Focus stays on quality and getting things just right every time.

See Also

Maximizing Car Data Transfer: Cutting-Edge Connectors and Cables

Boosting Car HSD Systems via USB Connection

Improving Data Transfer: High-Speed Car Connector Significance