Mastering Automotive Electrical Connectors Types for DIY Repairs

Learning about automotive electrical connectors types is important for DIY repairs. These connectors help keep your car's electrical parts working. Knowing these types helps you fix and care for your car better. Problems like loose wires, rust, and broken wires can hurt your car's performance. By understanding different connector types, you can solve these issues easily. This knowledge makes you confident in fixing things, so your car works well and stays reliable.

Overview of Automotive Electrical Connectors

Learning about car electrical connectors is important for fixing cars yourself. These connectors help your car's electric parts work well. Let's look at some common and special connectors you might see.

Common Types of Connectors

Blade Connectors

Blade connectors are used a lot in cars. They have a flat metal piece that fits into a slot. You find them in fuse boxes and other parts. They are easy to connect and disconnect, great for quick fixes.

Bullet Connectors

Bullet connectors are round and connect wires securely. They have male and female ends that fit together tightly. These are good where you need strong connections, like in lights.

Butt Connectors

Butt connectors join two wires end-to-end. Use them to extend or fix wires by crimping the ends together. They keep wiring safe and connected.

Pigtail Connectors

Pigtail connectors have a wire with a connector on one end. They let you connect many wires to one spot, useful in audio systems.

Specialty Connectors

Weatherproof Connectors

Weatherproof connectors handle tough weather conditions well. They have seals to keep out water, dust, and heat. Use them outside or where it's wet for long-lasting use.

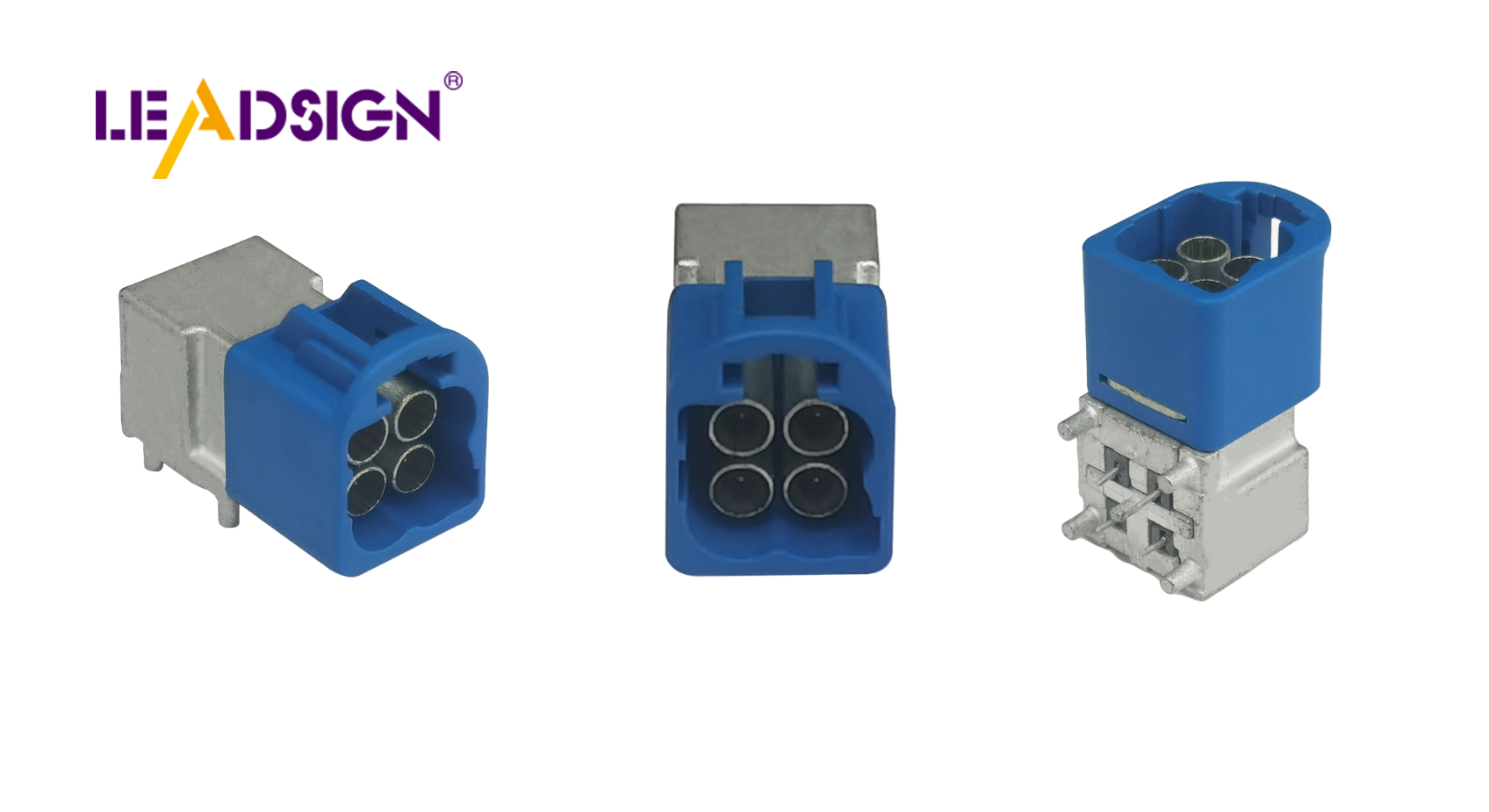

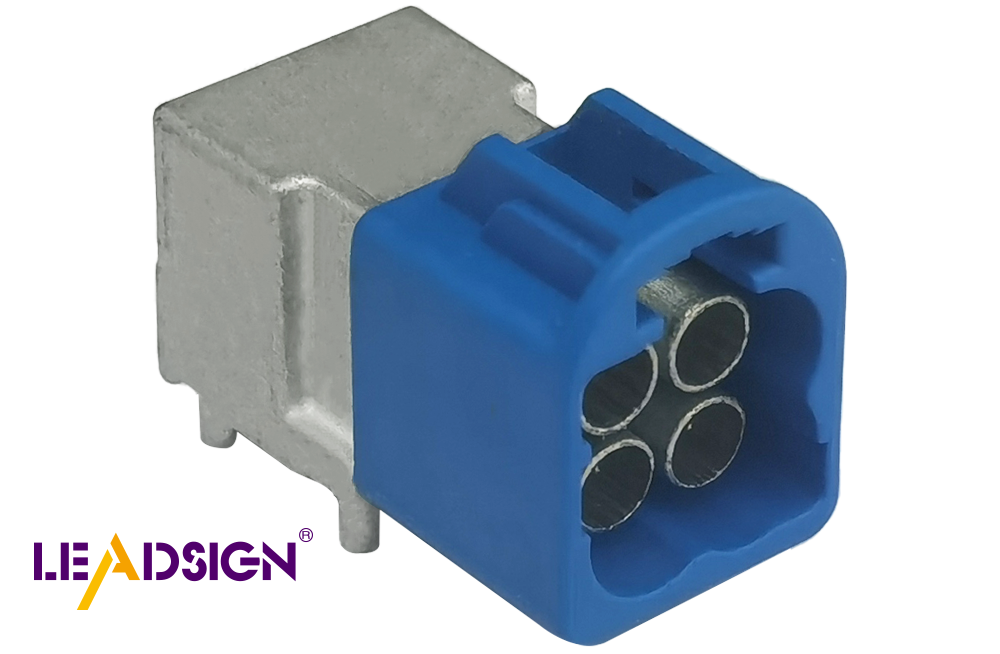

Multi-pin Connectors

Multi-pin connectors hold many pins in one place, connecting several wires at once. They're used in complex systems like engine controls.

High-Speed FAKRA-Mini Connectors

High-Speed FAKRA-Mini connectors are advanced types for fast data use. They're small but powerful, saving space while handling lots of data quickly.

By knowing these car electrical connector types, you can fix many things confidently yourself. Whether using blade or bullet types or special ones like weatherproof or high-speed FAKRA-Mini, understanding them helps improve your car repair skills.

Identifying Car Electrical Connectors

Knowing car electrical connectors is key for DIY fixes. You can use looks and guides to know different connectors.

How to Identify by Looks

Color Coding

Colors help you spot connectors fast. Makers use colors for jobs. Red might mean power, black could mean ground. Learning these helps you know what each connector does in your car.

Shape and Size

Connector shapes and sizes show what they do. Some have special shapes that fit only certain parts. A rectangle connector fits a matching socket, making sure it stays put. Watching these helps you match them right when fixing things.

Using Connector Guides and Manuals

Maker Guides

Maker guides give lots of info on connectors. They have pictures and words that show how connectors fit in your car's electric system. Reading these helps you use and place them right.

Online Help

Online help gives more ways to find out about connectors. Websites about car repairs often have pictures and tips from users. These sites let you learn from others' stories and fix common connector problems. Using these helps you do DIY fixes well.

By using these ways to know connectors, you can work with them confidently. Whether using color codes, shapes, or guides, these tools help you fix things easily.

Using Automotive Electrical Connectors for DIY Repairs

Tools Needed for Fixing Connectors

To fix car electrical connectors, you need the right tools. These tools help you work safely and well.

Crimping Tools

Crimping tools are key for attaching connectors to wires. They press the connector and wire together tightly. Pick a crimping tool that fits your connector type. This makes sure the connection is strong.

Wire Strippers

Wire strippers take off the plastic cover from wires without harming them. You need to see the wire to connect it properly. Use wire strippers for a neat cut, which helps in making a good connection.

Soldering Iron

A soldering iron helps make permanent connections. It melts metal to join wires and connectors securely. Use it when you need a strong bond that can handle car movement.

Steps to Fix Connectors

Follow these steps to fix car electrical connectors well.

Disconnect and Check Connectors

First, unplug the connector from the car's system. Look at it closely for cracks or rust. If it's damaged, replace it completely. Connector Experts say not to use broken connectors as they cause more issues.

Clean and Get Wires Ready

Clean wires before connecting them to a new connector. Remove dirt or rust with a brush or sandpaper. This makes sure of a good electrical link. Strip off insulation to show the metal part of wires.

Crimp and Secure Connections

Use a crimping tool to attach the connector to the wire firmly. Make sure it's tight and secure. If needed, use a soldering iron for extra strength so wires don't come loose due to shaking.

Safety Tips

When working with connectors, safety is very important.

Avoid Electrical Dangers

Always disconnect the battery first before touching electrical parts. This stops shocks or short circuits from happening accidentally. If you're unsure about handling these parts, get professional help. Connector Experts stress being careful with electric systems.

Ensure Tight Connections

Check all connections are tight enough not to come loose easily because loose ones can fail electrically causing risks too! Ensure every connector is attached correctly in place ensuring your vehicle's electric system works reliably!

By following these tips, you can repair automotive electrical connectors confidently using proper tools & methods keeping your vehicle’s electric systems running smoothly!

Knowing car electrical connectors is key for keeping your car safe and working well. These connectors help electricity move smoothly through the car, making it more reliable. By learning about them, you can fix things yourself and save money.

"Car connectors join electric parts to make circuits," showing why they matter in today's cars.

To get better at fixing cars, check out online guides and manuals. These give useful tips and advice for good repairs. Use this knowledge to keep your car running safely and smoothly.

See Also

Understanding HSD Connectors Used in Automotive Systems

Advantages of Using Fakra Connectors in Vehicles

Significance of Fakra Connectors for Today's Vehicles