How to Master Automotive Electrical Connector Types for Effective Use

Understanding the different automotive electrical connectors types is crucial for maintaining your car's health. These connectors facilitate connections between various components, such as the engine and radio. Incorrect usage can lead to issues like increased resistance due to wear and corrosion, resulting in failures. Such failures occur more frequently than in aircraft wiring, highlighting the importance of familiarizing yourself with these connectors. By gaining knowledge about automotive electrical connectors types, you can prevent problems and enhance your car's performance.

Understanding Trends in Automotive Electrical Connectors Types

What are Automotive Electrical Connectors Types?

Definition and Purpose

Automotive electrical connectors are key parts in cars. They link different circuits to let power and signals move smoothly. These connectors have many shapes and sizes, each made for a special job. Knowing these types helps your car's electrical systems work well.

Importance in Vehicle Systems

In cars, these connectors are very important. They join main parts like the engine, lights, and radios. Without good connectors, these systems might not work right, causing safety problems. For example, a bad connector in brakes can cause them to fail. So, picking the right connector is crucial for keeping cars safe and working well.

Common Automotive Electrical Connectors Types

Blade Connectors

Blade connectors are flat metal pieces that fit into slots. They're used a lot in cars because they're simple and reliable. You can find them in fuse boxes where quick connections are needed.

Pin Connectors

Pin connectors have pins that go into holes. They're used when a strong connection is needed. You'll see them in engine controls and other important places.

Butt Connectors

Butt connectors connect two wires end-to-end. They're great for fixing or extending wires in cars. Using them ensures wires stay connected well.

Ring Connectors

Ring connectors have round ends that fit over bolts or screws. They're used to attach wires to grounding points or terminals, making sure connections stay stable.

Specialized Connectors

Weatherproof Connectors

Weatherproof connectors handle tough weather conditions well. They have seals to keep out water and dirt, perfect for outdoor uses like headlights.

High-Temperature Connectors

High-temperature connectors resist extreme heat with special materials. They're found near engines or exhausts where it's hot, keeping connections steady even when it’s very warm.

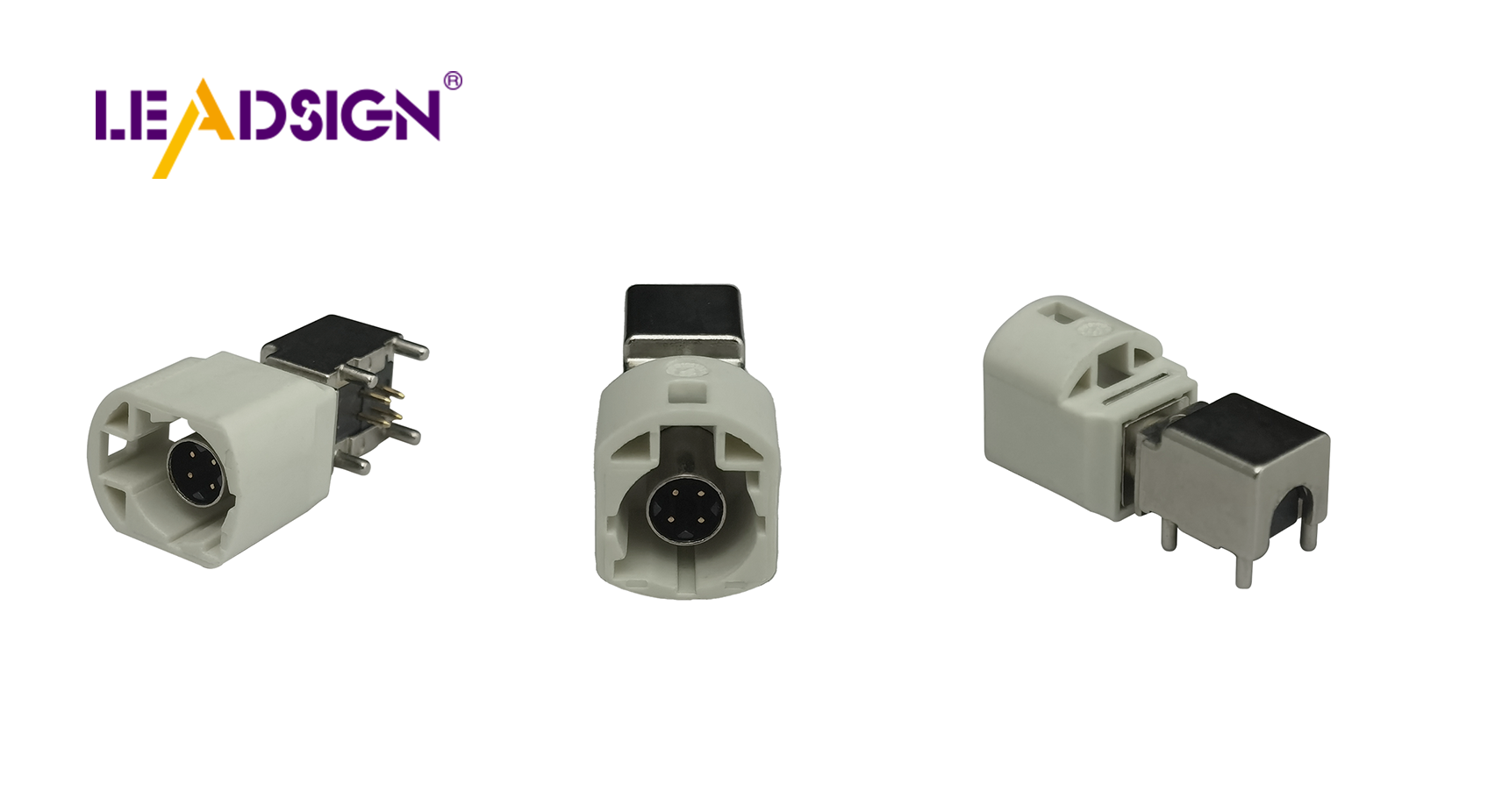

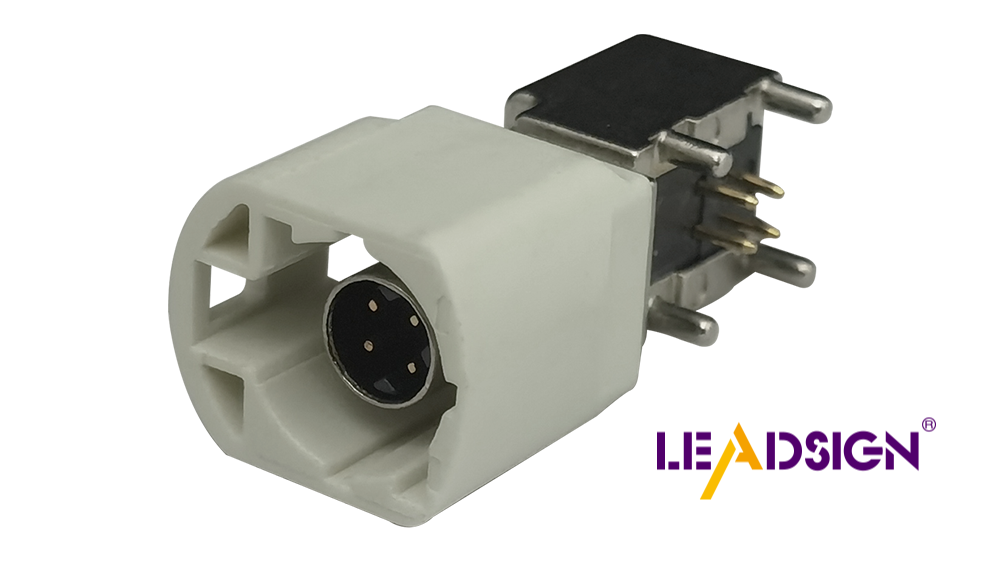

Multi-Pin Connectors

Multi-pin connectors hold many pins together in one place. They're used where lots of connections are needed at once, like buses or trucks with Deutsch HD30 Series which provide strong links that resist shaking.

Picking the Best Connector for Your Car

Choosing the right automotive electrical connectors types is important. It helps your car work well. Think about a few things before deciding.

Things to Think About

Power Needs

First, check how much power your car parts need. Different automotive electrical connectors types handle different power levels. For example, engine connectors need more power than light ones. Knowing this helps you pick connectors that don't overheat and work well.

Weather Conditions

Next, think about where you'll use the connectors. Some, like weatherproof ones, are made for bad weather. If your car goes through rain or dirt, choose sealed connectors. This stops rust and makes them last longer.

Material and Strength

The material of connectors is also key. High-temperature ones resist heat and are good near engines. Check if the connector material is strong enough for your car's needs.

Matching Connectors to Jobs

Engine Parts

For engines, you need strong connectors that handle lots of power and heat. Multi-pin ones like Deutsch HD30 Series are great for this because they're tough.

Lights

For lights, pick easy-to-use connectors like blade ones. They make sure lights work right in dark or bad weather.

Sound Systems

For sound systems, use pin connectors that keep signals clear. They help with good sound quality and no signal loss.

By thinking about these things and choosing the right automotive electrical connectors types, you can make sure all parts of your car work better.

Best Practices for Effective Use

Using automotive electrical connectors types well means picking, installing, and caring for them right. Here are tips to help you use your connectors best.

Installation Tips

Proper Crimping Techniques

Crimping joins wires to automotive electrical connectors types. Use a good crimping tool for strong links. Put the wire in the connector and press the tool hard. This action squeezes them together tightly. A tight crimp stops wires from slipping out and keeps electricity flowing well.

Ensuring Secure Connections

After crimping, gently pull the wire to check it stays put. Tight connections matter because loose wires cause problems. Use connectors with locks to keep them secure. Locks stop accidental disconnections, especially where engines shake a lot.

Maintenance and Troubleshooting

Regular Inspection and Cleaning

Check your automotive electrical connectors types often for wear or damage signs. Look for rust if water gets inside. Clean them with contact cleaner to remove dirt. Clean connectors work better and last longer.

Identifying and Replacing Faulty Connectors

If lights flicker or systems fail, bad connectors might be why. Look for bent pins or cracked parts on connectors. Replace damaged ones quickly to avoid more issues. Right automotive electrical connectors types make vehicle systems reliable.

Expert Testimony: "Electrical connectors are key in many products but can cause problems."

Follow these tips to keep your automotive electrical connectors types working well so your car runs smoothly.

Knowing about automotive electrical connector types helps your car work better. When you learn and use this info, your car's systems stay reliable.

Use What You Know: Take what you've learned to make sure connections in your car are safe and work well. Doing this stops problems before they start and makes your car's electrical parts last longer.

Get More Help: For tricky systems, think about looking at more resources or asking a pro for help. Experts can give advice just for you, making sure everything works great and stays safe.

See Also

Exploring HSD Connectors' Role in Automotive Sector

Significance of HSD Connectors in Auto Sector

Significance of FAKRA Connectors in Auto Usage