Maintaining Vehicle Connectors: A Guide for Automotive Networking

Vehicle connectors are very important for car networks. They help different electronic parts in your vehicle communicate with each other easily. Checking these connectors often is important to prevent rust and keep them functioning well. Rust can cause connectors to fail, leading to various electronic problems. By taking care of your vehicle connectors, they last longer and perform better. This proactive approach saves you money on major repairs and keeps your vehicle running smoothly over time.

Key Takeaways

Regularly check your vehicle connectors every three to six months to prevent rust and ensure optimal performance.

Use essential tools like OBD II code readers and compressed air to effectively inspect and clean connectors.

Look for signs of wear, such as rust or cracks, to catch potential issues before they lead to costly repairs.

Incorporate dielectric grease during cleaning to protect connectors from moisture and corrosion.

Upgrade to weatherproof connectors to enhance durability and reliability in harsh conditions.

Implement protective coatings and environmental shields to safeguard connectors from damage and extend their lifespan.

Stay informed by consulting experts and reading reviews to choose the best connectors for your vehicle.

Checking and Finding Common Problems

Checking car connectors often is key to keeping your car's network working well. Spotting problems early stops bigger issues later.

How to Check Car Connectors

Tools You Need

To check car connectors right, you need some tools. Here’s what you’ll need:

OBD II Code Readers: These help find engine troubles in cars made after 1996.

Connector Vision Inspection System: This lets you see connectors clearly so nothing is missed.

Small Wire Brush: Good for cleaning dirt that blocks your view.

Compressed Air: Blows away dust from tricky spots.

Steps to Look at Connectors

Turn Off the Engine: Make sure the car is off and cool for safety.

Find the Connectors: Locate the connectors to check. Use a Diagnostic Connector if needed to talk with the car's computer.

Look for Dirt and Debris: Clean with a wire brush or air.

Check Connections are Tight: Make sure all parts are snug and not loose.

Use the Connector Vision Inspection System: This tool finds hidden problems not easy to see.

Spotting Wear or Rust Signs

Knowing wear or rust signs helps avoid surprises.

Common Rust Signs

Rust looks like green or white powder on terminals, showing water damage. Using waterproof connectors helps stop this, making your car’s system last longer.

Seeing Wear and Tear

Look for cracks or breaks in connector covers. Also, watch for color changes or burn marks, which mean heat or electric issues. A Connector Inspection Machine makes checking fast and easy.

By doing these steps, your car connectors stay in top shape, helping your car run smoothly.

Cleaning and Taking Care of Connectors

Keeping car connectors clean helps them work well and last long. Clean often to stop dirt and rust from messing up your car's electronics.

Easy Cleaning Steps

Things You Need for Cleaning

To clean car connectors, you need these things:

Dielectric Grease: Keeps water away from connectors.

Small Wire Brush: Cleans off dirt and junk.

Compressed Air Canister: Blows dust away from tight spots.

Soft Cloth: Wipes without scratching.

Isopropyl Alcohol: Safely cleans connectors.

How to Clean Different Connectors

Turn Off the Engine: Make sure the car is off and cool first.

Unplug the Connectors: Carefully take out the connectors you will clean.

Use Compressed Air: Blow away any loose dust or dirt.

Brush Off Dirt: Use a wire brush to get rid of stuck grime.

Wipe with Alcohol: Use a cloth with alcohol to clean them well.

Put on Dielectric Grease: Add a little grease to stop rust later.

Plug Back In Connectors: Put them back in tightly.

Regular Care Tips

How Often to Check

Check your car connectors every three to six months. If you drive in tough places, check more often.

Tips for Long Life

Keep Dry Storage: Park your car where it's dry to avoid moisture.

Choose Sealed Connectors: Use sealed ones for better strength and trustworthiness.

Look for Damage Signs: Check for breaks or damage; replace bad ones quickly.

Use Protective Coatings: Protect connectors from weather harm.

Expert Advice: "Listening to users and experts can help find good connector choices. Read reviews and ask auto experts for advice."

By doing this cleaning, your car's connectors stay strong, helping your car’s electronics work smoothly.

Upgrading and Protecting Connectors

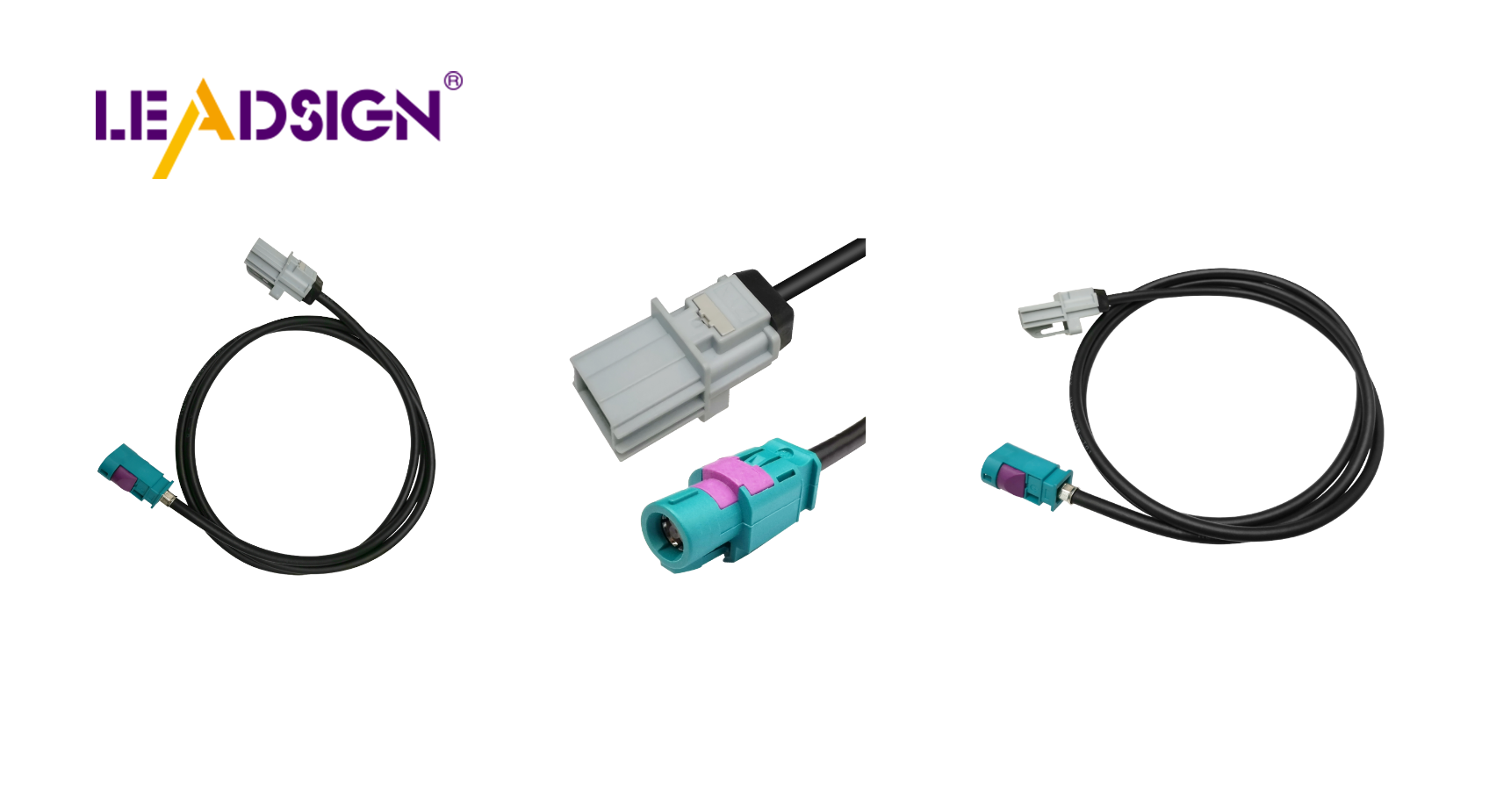

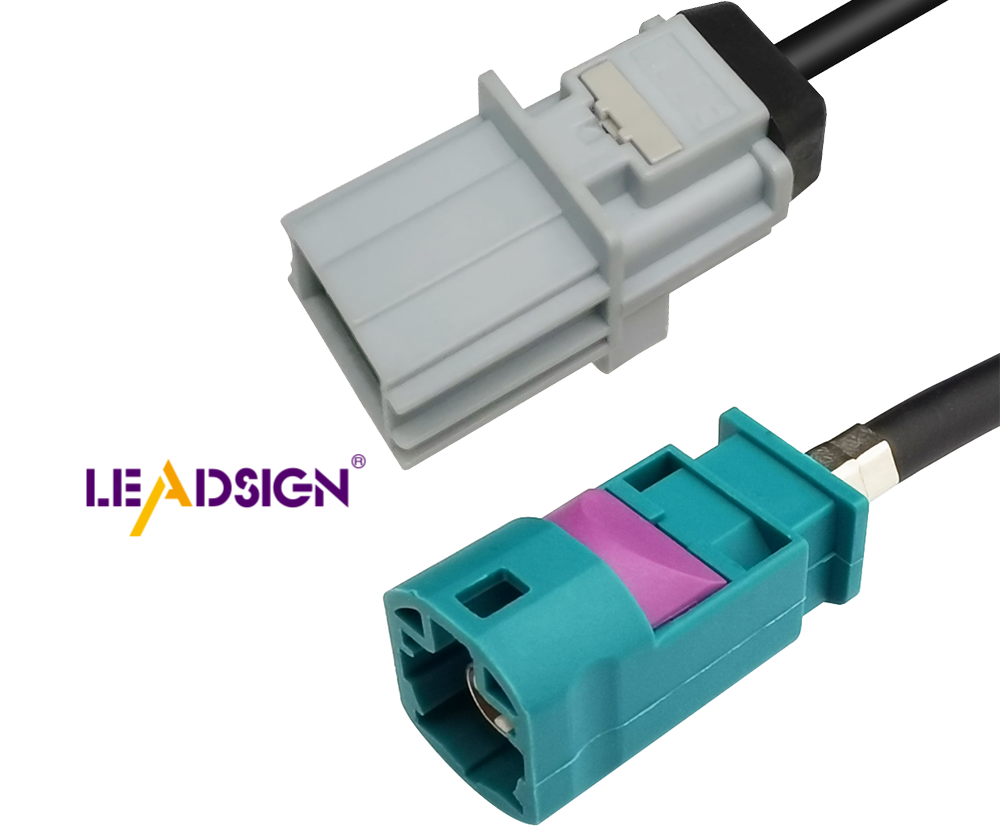

Changing your car connectors to weatherproof ones makes them last longer. These special connectors handle tough weather, keeping your car's electronics working well.

Why Use Weatherproof Connectors

Weatherproof connectors are better than regular ones. They don't rust or break easily, lasting a long time. This is important in places with water, dust, and dirt. By upgrading, you keep important connections safe and working even in bad conditions.

Special Parts of Weatherproof Connectors

Weatherproof connectors have cool features for cars:

Sealed Design: Stops water and dust from getting inside.

Durable Materials: Made from strong stuff that doesn't wear out fast.

High Retention Force: Keeps parts tight so they don't come apart.

How to Put in New Connectors

Putting in weatherproof connectors needs care:

Select the Right Connector: Make sure it fits your car.

Prepare the Area: Clean around it to get rid of dirt.

Follow Manufacturer Instructions: Read and do what the guide says.

Test the Connection: Check if it's on right after putting it in.

Keeping Connectors Safe from Damage

Protecting your car connectors from damage helps them work well.

Using Protective Coatings

Put coatings on to stop rust and wetness. These make a shield so water can't touch metal parts. Do this often for best results.

Adding Environmental Shields

Shields give extra safety by covering connectors. They stop damage from bad weather and hits. They're great for places with wild weather.

By upgrading and protecting your car connectors, you make sure your car's electronics stay good. This smart move keeps your car running well without problems.

Taking care of car connectors is very important. It helps your car's electronics work well. Check and clean them often to avoid surprises and big repair bills. Use weatherproof connectors for longer-lasting parts. This saves money and makes your car work better. Regular care keeps your car safe and running smoothly. Spend time on connector care, and driving will be safer and more reliable.

See Also

Maximizing Efficiency In Automotive Data Transfer Solutions

Boosting Automotive Data Flow With Fast Connectors

Transforming Vehicle Connectivity With HFM Connector Benefits

Understanding Ford Fakra Connectors: A Comprehensive Overview