A Beginner's Guide to Maintaining Vehicle Connectors

Vehicle connectors are important for your car's electronics to work. Ignoring them can cause problems and costly repairs. Taking care of these connectors helps your car last longer. Keeping vehicle connectors clean ensures everything runs well and prevents breakdowns.

Key Takeaways

Regularly clean your vehicle connectors every six months to prevent rust and ensure optimal performance. Use compressed air and dielectric grease for protection.

Inspect connectors frequently for wear and damage, such as cracks or discoloration, and replace any faulty parts promptly to avoid costly repairs.

Consider using weatherproof connectors to enhance durability and reliability, as they protect against moisture and dust, reducing the risk of electrical issues.

Understanding Vehicle Connectors

Types and Functions of Vehicle Connectors

Vehicle connectors are key parts of car systems. They help electricity move between parts, keeping things working well. This includes the engine, lights, and sensors. Without good connectors, your car might not work right or could stop working.

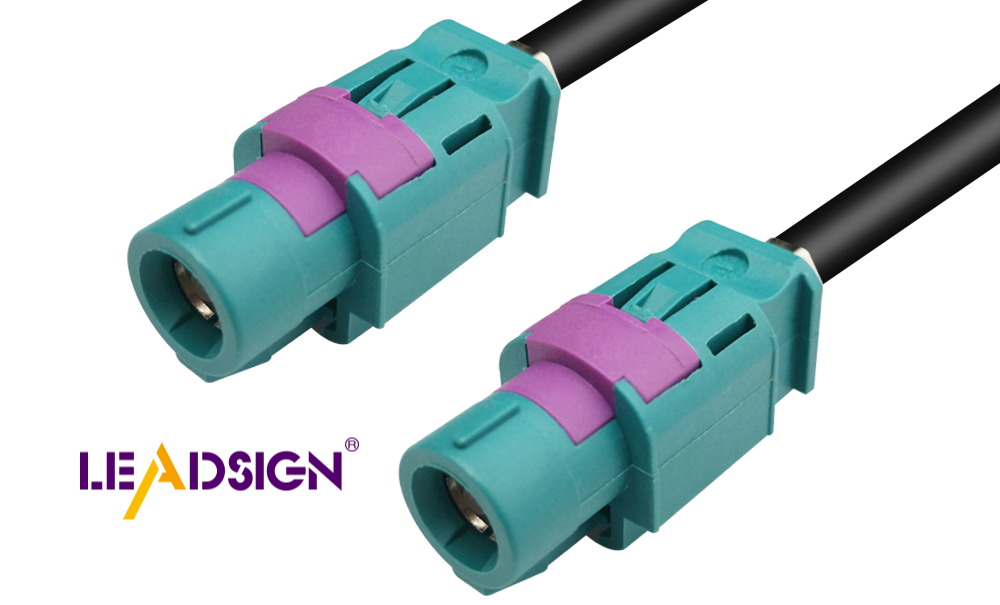

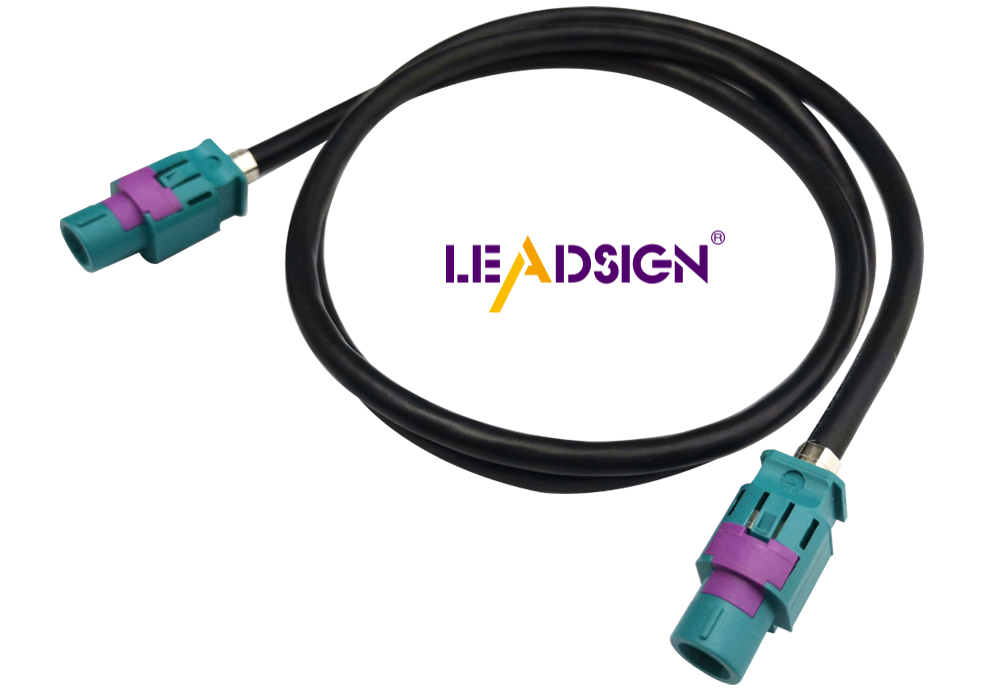

There are different connectors for different jobs. Bullet connectors are used in audio systems and are easy to unplug. Scotch locks let you join wires fast without cutting or soldering. Flat connectors fit small spaces, while round ones are good for outdoor lights. Square connectors work with engine sensors, and rectangular ones handle complex systems. Pin and socket connectors power the engine control unit. Barrel connectors send signals for GPS and audio. Each type helps your car’s wiring work properly.

Common Materials and Their Durability

The materials in connectors affect how long they last. Copper and brass are strong and conduct electricity well. Some connectors are made to resist water and rust. These are good for wet or tough conditions.

The inside parts are often brass or bronze, while the outside protects them. This design makes them strong, even in rough conditions. Picking the right materials keeps connectors working longer and prevents damage.

Importance of Proper Installation

Installing connectors the right way is very important. If done wrong, it can be dangerous. Wrong connectors might leave wires uncovered, causing shocks. Bad connections can lead to shorts, overheating, or even fires. Using the wrong connectors can also harm your car’s wiring.

To avoid problems, always use the right connectors for your wires. Installing them properly keeps your car safe and makes connectors last longer.

Essential Tips for Wiring Connector Maintenance

Cleaning Connectors Safely

Clean connectors to keep them working and lasting longer. Use compressed air or a soft brush to remove dirt. Wipe surfaces with a cloth or alcohol swab. Avoid sharp tools that might scratch or break connectors. Use special tools made for cleaning connectors instead.

Protect connectors from moisture by using covers or seals. For unsealed connectors, apply dielectric grease after cleaning. This grease keeps connections safe from rust and damage. Clean connectors every six months or more often in tough conditions.

“Every six months, or more often in harsh conditions, clean 7-way connectors with a plug-and-socket brush and electrical cleaner. After cleaning, reapply dielectric grease to stop corrosion.”

Inspecting for Wear and Damage

Check connectors often to avoid costly repairs. Look for cracks, loose parts, or discoloration. Check for rust or damage on pins and sockets. Also, inspect wires for fraying or melted plastic.

Fix any damage as soon as you see it. Replace broken parts to keep connectors working well. Regular checks and repairs prevent bigger problems later.

Protecting Against Corrosion

Corrosion happens often in wet or salty places. To stop it, clean connectors with emery paper and spirits. Spray them with contact cleaner or WD40 to remove moisture. Use corrosion-resistant grease for extra protection.

Seal connections to block water and prevent rust. Use plastic tubes, cable ties, and desiccant to keep them dry. Adding connector grease creates a seal and makes connectors last longer.

Recommended Tools and Products

The right tools make connector care easier and safer. Clean with a plug-and-socket brush, air, or a soft brush. Use alcohol swabs or electrical cleaners for cleaning.

Use special tools to remove or insert connectors without damage. Add a thin layer of dielectric grease to protect pins from rust. Follow torque guidelines to avoid over-tightening. Use covers or seals to protect connectors from heat and water. These steps will help keep your connectors in good shape.

Troubleshooting Common Problems

Spotting and Removing Corrosion

Corrosion is a usual problem with car connectors. It happens because of water, electricity, dust, or chemicals. Corrosion creates a layer that blocks electricity, causing weak signals. Dust and chemicals can also stop electricity, leading to bad connections.

To fix corrosion, clean connectors with sandpaper and contact cleaner. Use plastic covers and drying packs to keep water out. Add anti-rust grease after cleaning to stop future corrosion. Clean and seal connectors often to keep them working well.

Repairing Loose or Bad Connections

Loose or bad connections can mess up your car’s systems. To fix them, follow these steps:

Get tools like a tester, wire cutters, and crimpers.

Unplug the car battery to stay safe from shocks.

Take out the bad connector by pressing or unscrewing it.

Attach a new connector by crimping and soldering wires tightly.

Plug the battery back in and test the connection.

Check and care for connectors often to avoid repeated problems.

Finding Electrical Problems

Electrical problems in connectors can be hard to find. Use tools like code readers to check for errors. Test voltage and resistance with a multimeter. Tools that show live data can help spot sudden changes. Special tools for car systems can find communication issues. These tools make fixing electrical problems easier.

Knowing When to Change Connectors

Some connectors wear out or break over time. Look for rust, broken parts, or weak performance. Test voltage and current with a multimeter. If the results are bad, replace the connector to fix the issue. Regular checks help you know when a connector needs replacing.

Preventative Measures and Upgrades

Why Use Weatherproof Connectors

Weatherproof connectors are great for keeping your car reliable. They block out moisture and dust, working well in tough conditions. These connectors stop rust, so they last longer and need fewer replacements. By keeping water out, they prevent electrical problems and save money.

Weatherproof connectors also seal connections tightly to stop oxidation. This keeps them working properly over time. They can be used in cars, boats, and factories. Switching to weatherproof connectors makes your car’s wiring more dependable.

How Dielectric Grease Helps

Dielectric grease is easy to use and protects connectors well. It keeps out water, dirt, and rust, which can cause damage. The grease stops layers from forming that block electricity, keeping signals strong.

Adding a small amount of grease to connectors protects them from harm. This simple step saves money on repairs and keeps your wiring working longer.

Making a Maintenance Plan

Regular checks keep your car’s connectors in good shape. Look at them every six months for damage or rust. Clean them with the right tools and add grease to stop moisture. Replace broken connectors quickly to avoid bigger problems.

A schedule helps you find issues early and keeps your car running well. Regular care makes connectors last longer and prevents sudden failures.

Storing Your Vehicle Safely

If not using your car for a while, store it right. Clean the connectors to remove dirt and check for damage. Fix any problems before storing. Use proper tools to avoid breaking connectors.

Keep connectors safe from water and heat by sealing them or using grease. Don’t tighten them too much to avoid cracks. These steps keep connectors in good shape during long storage.

Taking care of car connectors keeps your car working well. Checking them often stops problems and saves money. Clean them twice a year to avoid issues. Use materials that resist rust and add special grease for protection. Fix damaged connectors and use sealed ones for safety. A good care plan helps your car’s wires last longer and work better.

FAQ

How often should you clean vehicle connectors?

Clean vehicle connectors every six months. In wet or salty places, clean them more often. This stops rust and keeps them working well.

What tools do you need for connector maintenance?

Use a small brush, air blower, and alcohol wipes to clean. A multimeter checks connections, and grease stops rust and water damage.

Can you fix a damaged connector, or should you replace it?

Fix small issues like loose pins. Replace connectors with bad rust, broken parts, or weak signals to stay safe.

See Also

Understanding Ford Fakra Connectors: A Complete Overview

An In-Depth Look at HSD Connectors for Users

Fakra Connectors Explained: Benefits, Uses, and Setup Advice

Unveiling the Advantages of Fakra Connectors in Vehicles

Fundamentals of HSD Connectors Within Automotive Applications