Maintaining Automotive Plugs and Connectors Made Easy

Automotive plugs and connectors are key to your car's electricity. They help power and signals move between important parts, like brakes and sensors. If these connectors fail, small problems can cause big issues. Regular care of automotive plugs and connectors keeps them working well and stops rust or damage. Taking care of them makes them last longer and avoids expensive fixes. By checking these parts, your car stays safe and works well daily.

Key Takeaways

Regularly inspect automotive plugs and connectors to catch small issues before they escalate into costly repairs.

Use contact cleaners and dielectric grease to keep connectors clean and protected from corrosion and moisture.

Choose the right type of connector for your specific application to ensure strong and reliable connections.

Handle connectors with care during installation to avoid damage; use proper tools like crimpers and soldering kits for secure connections.

Implement preventative measures, such as using weatherproof covers, to extend the lifespan of connectors in harsh conditions.

Test connections with a multimeter to ensure they are secure and functioning properly, especially after cleaning or repairs.

Keep extra connectors and essential tools on hand for quick fixes to minimize downtime and maintain vehicle safety.

Understanding Automotive Plugs and Connectors

Automotive plugs and connectors are important for your car's electrical system. They help different parts of the car work together smoothly. Let’s look at the types of connectors and why they matter.

Types of Automotive Electrical Connectors

In cars, there are many kinds of electrical connectors. Each type has a job to make sure connections stay strong.

Blade Connectors

Blade connectors are very common in cars. They have a flat metal piece that fits into a slot. These are simple to use and work well for small tasks like lights or sensors. Their easy design makes them great for quick fixes.

Pin and Socket Connectors

Pin and socket connectors are stronger than blade connectors. They have a pin that fits tightly into a socket. These are used in important systems like engines or transmissions. They are tough and work well in hard conditions.

Weatherproof Connectors

Weatherproof connectors are made for outdoor or open areas. They have seals to block water, dirt, and dust. Newer designs can handle tough weather, making them good for GPS or radios. They keep connections safe in any weather.

Applications of Automotive Wiring and Connectors

Car wiring uses connectors to send power and signals to different parts. Here are some places where they are very useful:

Electrical Systems (e.g., Lighting, Sensors)

Connectors help lights and sensors work properly. They keep wires and parts connected, stopping flickering lights or broken sensors.

Engine and Transmission Connections

In engines and transmissions, connectors control fuel and gear shifts. Good connectors here keep the car running smoothly and avoid big problems.

Infotainment and Communication Systems

Modern cars have systems for music and calls that need connectors. These connectors help radios and Bluetooth work without interruptions.

Pro Tip: Pick strong connectors like Molex or 3-pin ones. They last long and work well in cars.

Knowing about different connectors helps you see their value in your car. From simple blade connectors to weatherproof ones, each type keeps your car safe and working well.

Maintenance Tips for Automotive Plugs and Connectors

Taking care of automotive plugs and connectors is simple. With easy steps, you can keep them working well, avoid expensive repairs, and ensure your car runs smoothly. Here are some useful tips to maintain connectors.

Regular Electrical Connector Maintenance

Checking your connectors often is the first step. Regular inspections help you find small problems before they become big ones.

Inspecting for Loose or Damaged Connectors

Look at your connectors closely. Are they loose, cracked, or worn out? Loose connectors can cause electrical problems. Damaged ones might stop working completely. If you see issues, fix or replace them quickly. For example, one company saved money by fixing connector problems early, avoiding bigger failures later.

Identifying Corrosion, Dirt, or Debris

Corrosion is bad for connectors. It weakens them and causes failures. Look for green or white buildup on metal parts. Dirt and debris can also block connections. Regular checks help you find these problems early, keeping connectors reliable.

Pro Tip: Check your connectors every few months, especially in bad weather.

Cleaning and Protecting Connectors

Cleaning and protecting connectors helps them last longer. A little effort now can save you trouble later.

Using Contact Cleaners and Soft Brushes

Use a contact cleaner to remove dirt, grease, and corrosion. A soft brush can clean tough grime without harming the metal. Let connectors dry fully before reconnecting them. This keeps your connections strong and dependable.

Applying Dielectric Grease for Corrosion Resistance

Dielectric grease protects against moisture and corrosion. Add a small amount to metal parts after cleaning. It creates a barrier to keep water and dirt out. Many experts use this method to keep connections lasting longer.

Did you know? A tool company avoided costly repairs by using grease on connectors. This simple step reduced failures.

Preventative Measures for Longevity

Preventative care helps connectors last longer. Smart choices now can make a big difference later.

Using Weatherproof Covers and Seals

Weatherproof covers and seals protect connectors from rain, snow, and dirt. These are great for connectors outside, like those for GPS or radios. Using weatherproofing now can stop corrosion in the future.

Ensuring Proper Storage and Handling

Handle connectors carefully. Don’t pull wires or force connections. Store extra connectors in a clean, dry place. Good handling and storage keep connectors ready to use.

Quick Tip: Match connectors with the right wire size to avoid problems.

By following these tips, you can keep automotive plugs and connectors in great shape. Regular checks, cleaning, and smart care help avoid corrosion and keep them working well.

Best Practices for Installing Automotive Plugs and Connectors

Installing automotive plugs and connectors the right way is important. It helps them work well and avoids future problems. Follow these steps to make strong connections that last.

Preparing for Installation

Getting ready is the first step for a good connection. Make sure everything is clean and set to go.

Cleaning and Stripping Wires Before Installation

Clean the wires before starting. Dirt or grease can cause weak connections. Use a soft cloth or cleaner to wipe off any debris. After cleaning, carefully strip the wire ends. Remove just enough insulation to fit into the connector. Don’t cut too much, or the wires might get damaged.

Pro Tip: A wire stripper tool helps strip wires safely. It avoids cutting the wire strands by mistake.

Matching Connectors with Appropriate Wire Sizes

Pick the right connector for the wire size. If they don’t match, the connection can be loose or fail. Check the wire and connector specs to make sure they fit.

Quick Tip: Double-check the connector size before installing. This small step can save you trouble later.

Crimping vs. Soldering in Automotive Wiring

To secure wires, you can crimp or solder them. Both methods have good and bad points.

Pros and Cons of Crimping

Crimping is a common method for car wiring. It’s fast and doesn’t need heat. Put the wire into the connector and use a crimping tool to secure it. This makes a strong bond.

Pros:

Quick and simple.

No heat tools needed.

Works well in moving or vibrating areas.

Cons:

Needs a good crimping tool for best results.

Bad crimping can make weak connections.

Expert Insight: “Crimping creates a strong bond that handles vibrations in cars.”

Pros and Cons of Soldering

Soldering melts metal to join wires and connectors. It makes a strong, lasting bond, great for important connections.

Pros:

Very strong and durable.

Good for high-power uses.

Cons:

Takes more time and skill.

Heat can harm nearby parts if not careful.

Quick Tip: Use heat shrink tubing after soldering. It protects the connection and makes it stronger.

Ensuring Proper Grounding

Grounding is very important in car wiring. Without it, systems might not work right.

Techniques for Secure Ground Connections

For a good ground, connect the wire to clean, bare metal. Use a ring terminal for a tight fit. Tighten it firmly, but don’t overdo it, or you might damage it.

Pro Tip: Lightly sand the metal surface to remove rust or paint. This helps the connection work better.

Avoiding Common Grounding Mistakes

Grounding problems often come from simple errors. Don’t connect to painted or rusty surfaces. Avoid loose or small terminals. Always test the ground with a multimeter to make sure it works.

Did You Know? Bad grounding can cause flickering lights or sensor problems.

By following these tips, your automotive connectors will work well. Whether you crimp or solder, focus on cleaning and grounding for the best results.

Troubleshooting Common Problems with Automotive Electrical Connectors

Even with care, automotive electrical connectors can still have problems. Knowing how to fix them saves time and money. Let’s look at common issues and simple solutions.

Loose or Weak Connections

Loose connections can cause annoying car electrical problems. These may lead to flickering lights, broken sensors, or system failures. Here’s how to fix them:

Finding and Fixing Loose Connectors

Check your car’s connectors carefully. See if any feel loose or don’t fit tightly. Wiggle them gently to check for movement. Push loose connectors back until they click or lock in place. For connectors with screws, tighten them gently but not too much.

Pro Tip: Use a multimeter to test connections. A steady reading means it’s secure, while changing numbers show it’s loose.

Replacing Old or Broken Connectors

If tightening doesn’t help, the connector might be damaged. Look for cracks, bent pins, or melted parts. Replace it with a matching connector. Make sure the new one fits the wire size and type for a good connection.

Quick Tip: Keep extra connectors handy for quick fixes when needed.

Corrosion and Rust

Corrosion is a big problem for automotive electrical connectors. It weakens them and can cause failures. Fixing corrosion early is very important.

Cleaning Corroded Connectors

If you see green or white buildup on metal parts, clean it fast. Disconnect the connector and use a contact cleaner or baking soda with water. Scrub gently with a soft brush. Rinse with water and let it dry before reconnecting.

Did You Know? Adding dielectric grease after cleaning stops most corrosion problems.

Stopping Corrosion Before It Starts

To stop corrosion, add a thin layer of dielectric grease to metal parts. This keeps water and dirt out. Use weatherproof covers for connectors in tough areas like near the engine.

Pro Tip: Check connectors in wet or dirty spots often to catch corrosion early.

Broken or Faulty Connectors

Damaged connectors can mess up your car’s electrical systems. Fixing them quickly keeps your car running well.

Spotting Damage

Look for broken pins, melted plastic, or frayed wires. Damaged connectors often cause weak or failed connections. Check connectors in hot or vibrating areas since they wear out faster.

Quick Tip: If you see burnt connectors, check the wiring harness for damage too.

Replacing with the Right Connector

When replacing, pick a connector that matches the old one. Clean and strip the wires before attaching the new connector. Use crimping or soldering for a strong connection. Cover it with heat shrink tubing for extra protection.

Did You Know? High-quality connectors last longer and reduce future problems.

By fixing these issues, your automotive electrical connectors will stay in great shape. Regular checks, cleaning, and quick repairs keep your car’s electrical systems working well.

Essential Tools and Accessories for Automotive Connector Maintenance

Taking care of automotive electrical connectors is easier with the right tools. These tools make the job simple and help connections last longer. Let’s look at the tools and accessories you need to keep connectors in good shape.

Tools for Maintenance and Cleaning

To keep connectors clean and working, you need proper tools. These tools help find and fix problems early.

Contact Cleaners and Brushes

Contact cleaners remove dirt, grease, and rust from connectors. They clean without harming the metal. Use soft brushes to gently scrub away tough grime. Together, they keep connectors clean and working well.

Pro Tip: Pick a contact cleaner made for electrical parts to avoid damage.

Multimeters for Testing Connections

A multimeter checks if connectors are working properly. It measures voltage, resistance, and continuity. This tool helps find weak or broken connections quickly.

Quick Tip: Test connectors after cleaning to make sure they work well.

Tools for Installation

Installing connectors needs care and the right tools. These tools help make strong and lasting connections.

Crimping Tools and Soldering Kits

Crimping tools tightly attach connectors to wires. They make strong bonds that handle movement. Soldering kits melt metal to join wires for a permanent connection.

Did You Know? Crimping is great for cars because it handles vibrations well.

Heat Shrink Tubing and Electrical Tape

Heat shrink tubing protects connections by sealing them from dirt and water. Electrical tape insulates wires and secures connections. Both make wiring stronger and last longer.

Pro Tip: Use heat shrink tubing after soldering for extra protection and a neat look.

Accessories for Protection

Protecting connectors from weather is as important as cleaning them. These accessories help connectors last longer.

Dielectric Grease

Dielectric grease stops moisture and rust. Apply a small amount to metal parts after cleaning. This keeps connections strong and safe.

Quick Tip: A thin layer of grease helps in bad weather.

Weatherproof Covers and Seals

Weatherproof covers protect connectors from rain, snow, and dirt. They are great for outdoor connectors like GPS or radio systems. Using them now can save money on repairs later.

Did You Know? Weatherproofing connectors makes them last longer in tough conditions.

With these tools and accessories, you can take care of automotive electrical connectors easily. Cleaning, testing, and protecting them ensures they work well and last a long time.

Taking care of automotive plugs and connectors is very important. Regular checks and cleaning stop big electrical problems. This helps your car work well and avoids costly repairs. Using proper tools during setup makes connections stronger and last longer. These easy steps save money and keep your car safe daily.

Remember: Check, clean, and protect your automotive electrical connectors often. This prevents expensive fixes and keeps your car running smoothly.

FAQ

Why do automotive connectors fail?

Automotive connectors fail for many reasons. A common cause is using cheap or low-quality parts. These parts are not as strong or reliable as genuine ones. High-quality automotive electrical connectors are tested to handle tough car conditions. Always pick genuine connectors to keep your car safe and working well.

Tip: Check your connectors often for wear, rust, or damage. Fix problems early to avoid bigger issues.

How do connectors help car electrical systems last longer?

Connectors are important for keeping car electrical systems strong. They are built to handle tough conditions like heat, cold, water, and vibrations. Good connectors with proper seals keep connections steady and reliable, even in bad weather.

Did You Know? Cars with strong connectors have fewer electrical problems, even in rough conditions.

What do connectors do in modern cars?

Connectors are key to modern car electrical systems. They link devices and sensors, helping parts work together smoothly. Without good connectors, systems like the engine, radio, and safety features wouldn’t work right.

Quick Fact: The quality of connectors affects how well your car performs.

How do connectors make repairs easier?

Connectors make fixing cars faster and simpler. If a part breaks, it’s easy to unplug and replace it without taking apart the whole car. This saves time and money on repairs.

Pro Tip: Use labeled or colored connectors to make future repairs quicker.

What are the main jobs of automotive connectors?

Automotive connectors send power and signals between car parts. They connect systems like the engine, lights, and sensors. Built to handle tough conditions, they keep your car running safely and smoothly.

Key Takeaway: Good connectors are important for your car’s safety and performance.

Why are wire connectors important in cars?

Wire connectors are small but very important. They carry electrical signals to power things like the engine and radio. Without them, car systems wouldn’t work right, causing safety and performance problems.

Fun Fact: One bad wire connector can mess up several car systems.

How can you stop corrosion in automotive connectors?

Corrosion is a big problem, but it’s easy to prevent. Use dielectric grease to block moisture. Cover connectors exposed to rain or dirt with weatherproof covers. Clean them regularly to keep them in good shape.

Pro Tip: Check connectors near the engine or under the car more often. These areas are more likely to have moisture.

What tools do you need to care for automotive connectors?

You need a few tools to take care of connectors. Use a contact cleaner and soft brush to clean dirt. A multimeter checks if electricity flows properly. Crimping tools, soldering kits, and heat shrink tubing help make strong connections during installation.

Quick Tip: Keep these tools handy for quick fixes and regular care.

Can you use one connector for all car systems?

No, different systems need specific connectors. For example, weatherproof connectors are best for outdoor parts like GPS. Pin-and-socket connectors work better for engines. Always use the right connector for the job to avoid problems.

Did You Know? Using the wrong connector can cause loose connections or system failures.

How often should you check your automotive connectors?

Check your connectors every few months. Also, inspect them if you notice problems like flickering lights or broken sensors. Regular checks help you find and fix issues early, saving money on repairs.

Reminder: Pay extra attention to connectors in wet, dirty, or very hot areas.

See Also

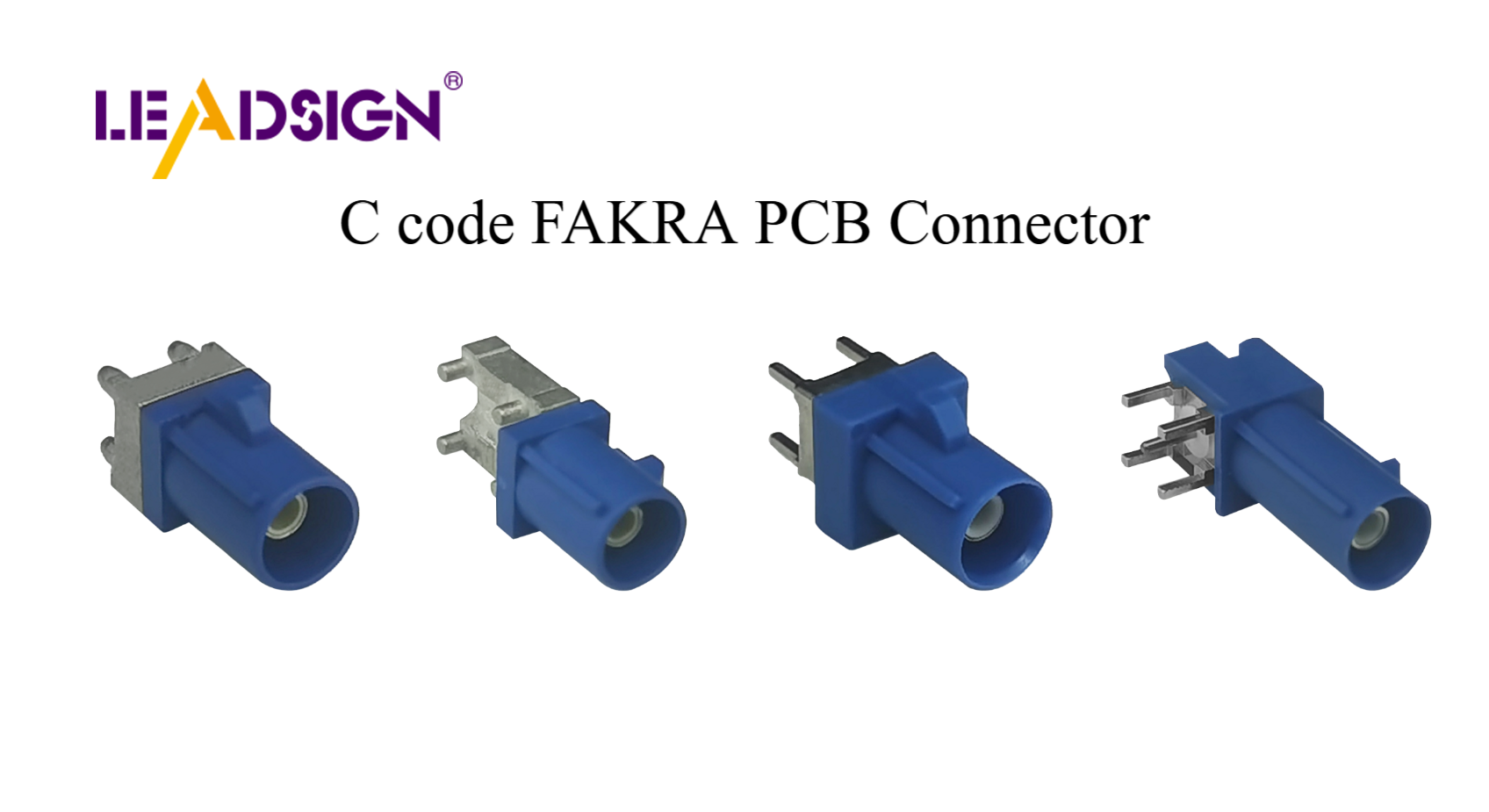

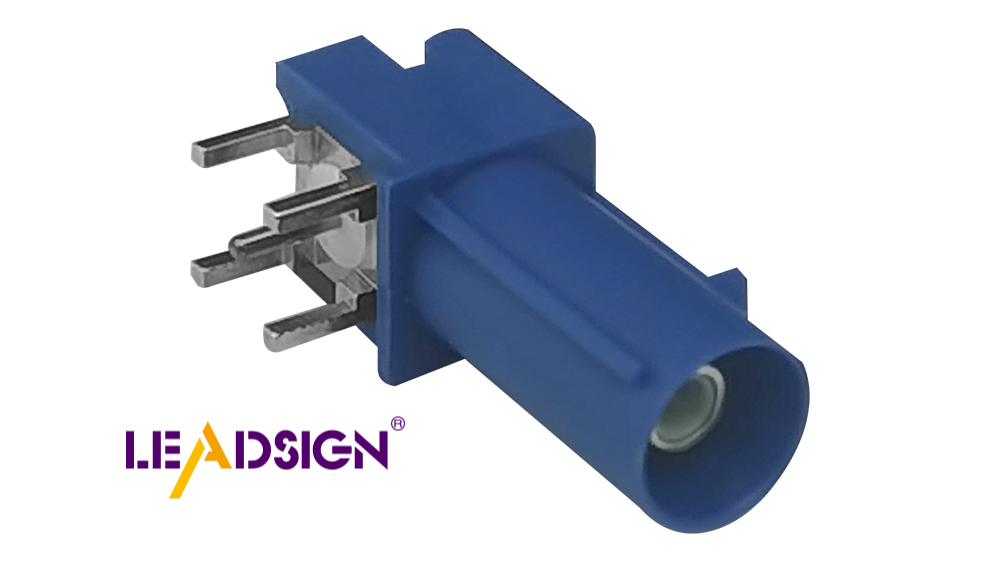

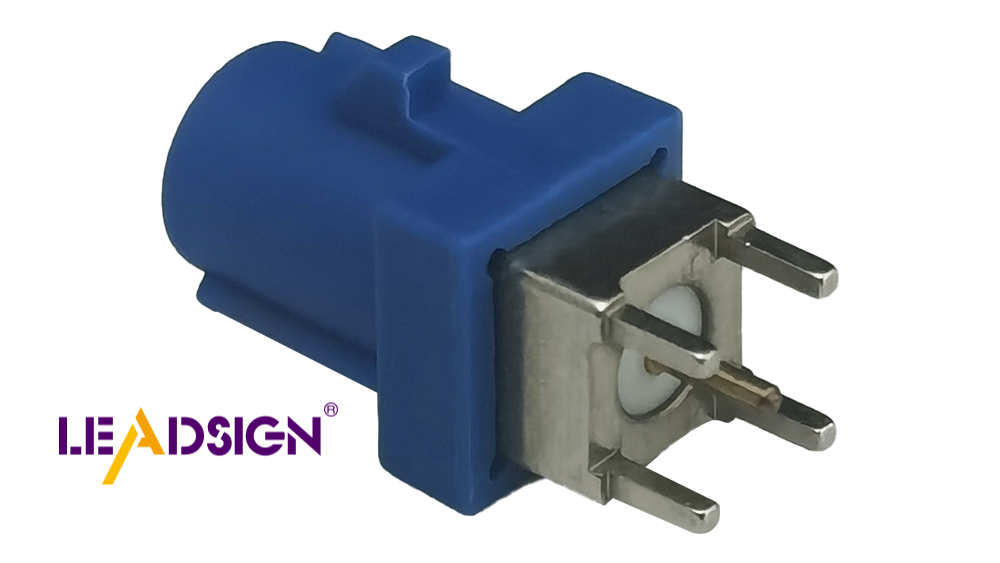

Why Fakra Connectors Are Essential for Today's Vehicles

Enhancing Vehicle Data Flow with Advanced Connectors

Key Role of FAKRA Connectors in Car Technology