Latest Developments in Wire Connectors Automotive Type

Wire connectors are important in cars today, and they represent one of the many automotive electrical connectors types that help power and systems work together. As car technology evolves, better wire connectors are needed to handle new tasks, such as being smaller and safer. They also need to be compatible with new technology. The market for car connectors was worth USD 6.71 billion in 2023 and is projected to grow to USD 8.76 billion by 2029. This growth highlights the significance of innovative ideas in connectors, especially as electric cars require specialized components.

Overview of Automotive Electrical Connectors

Car electrical connectors are very important. They help parts talk and share power in cars. These connectors keep cars working well and reliably.

Importance in Vehicle Systems

Role in Power Distribution

Connectors send power all over a car. They link parts like the engine, lights, and music systems. This makes sure each part gets enough power to work right. Chassis or panel connectors are key because they stick to the car's body, giving a strong hold for non-moving machines. This strength is needed for good power sharing in cars.

Impact on Vehicle Performance

A car needs good connections to work well. Strong connectors make sure signals and power move between parts easily. Splice or butt connectors join wires together forever, making a tough link that helps the car's wiring work better. These strong links stop power loss and keep the car running smoothly.

Basic Components and Functions

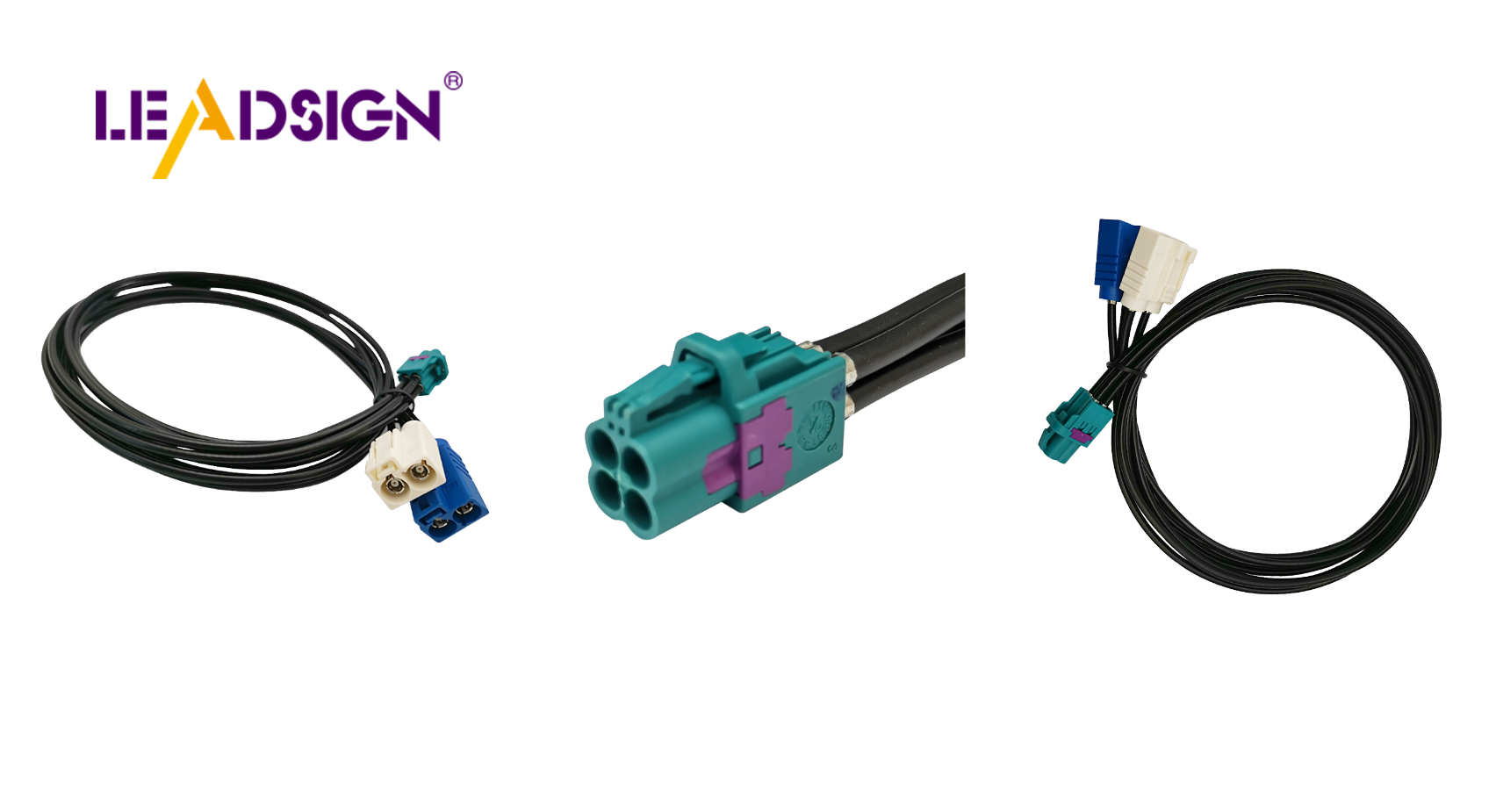

Automotive Electrical Connectors Types

There are different types of car electrical connectors, each doing special jobs in a car. Automotive pigtail connectors are important for keeping connections between things like sensors and lights strong. They help signals and power move easily, supporting the car's complex electric system. Different connector types let makers create solutions for electric and self-driving cars.

Common Materials Used

Makers use many materials to make these connectors last long and conduct electricity well. Metals like copper and aluminum conduct electricity great, while plastics protect them from damage. These materials help connectors survive tough conditions like heat changes and shaking in cars. Picking the right materials makes them last longer and keeps cars safe and efficient.

New Trends in Car Connectors

Smaller Size

Good Things About Tiny Connectors

Tiny connectors have many good points for cars. They save room, so more parts can fit in a car. This is helpful as cars get more gadgets and tech. Tiny connectors also make cars lighter, helping them use less fuel and go faster. By making connectors small, makers can design cooler and smaller car layouts.

Hard Parts of Making Small Connectors

Making tiny connectors is tricky. Engineers must keep them working as well as big ones. Their small size makes putting them together harder, needing careful work and smart ways to build them. Also, tiny connectors must handle tough car conditions like shaking, heat changes, and wetness. Solving these problems needs new ideas and better materials.

Better Efficiency

New Ideas in Power Flow

New ideas in power flow make car connectors work better. Makers are using better materials that waste less energy when sending power. These improvements help the car's electric parts work well by moving power smoothly between pieces. Less resistance means these connectors last longer and keep the car's electric system strong.

Saving Energy Features

Saving energy is big for new car connectors now. Makers add tech that uses less power, cutting down how much energy the car needs overall. These features help cars use less fuel and support eco-friendly goals too. By adding energy-saving tech to connectors, makers help cut cars' carbon footprints.

Safer Features

Better Covering and Safety

Safer features in car connectors mean better covering and safety tricks. These upgrades make sure they can handle hard times without failing. Better covering stops short circuits and lowers fire risks, making cars safer overall. Plus, safety features protect from things like water or dirt to keep them working long.

Meeting Safety Rules

Meeting safety rules is key for today's car connectors. Makers must follow strict rules to make sure their stuff is super safe. This means lots of testing to check how well they work under different situations. By following safety rules, makers give people safe cars they can trust.

Integration with Advanced Technologies

Connectors for Electric and Autonomous Vehicles

Electric and self-driving cars need special connectors. These connectors help car parts talk to each other. They must handle lots of data and power, which is important for electric engines and self-driving systems. Makers build strong connectors that can take tough conditions like heat and shaking. This keeps cars safe and working well.

Key Features of Connectors for Electric and Autonomous Vehicles:

Send lots of data fast

Built strong to last long

Work with electric car systems

More electric and self-driving cars mean more need for these connectors. Makers are creating better ones to keep up. These new connectors help cars connect better and stay safe. This is important as we move to smarter, greener cars.

Smart Connectors and IoT Integration

Smart connectors are a big step in car tech. They have tools inside that check how they work all the time. This helps fix problems before they happen, making cars more reliable. Smart connectors also let cars use Internet of Things (IoT) tech, so they can talk to other devices.

Benefits of Smart Connectors:

Watch how things work right now

Better car checks

Easy IoT use

Using IoT in car connectors makes new ways for cars to connect. Cars can talk to smart things like traffic lights, making driving better. As car tech grows, smart connectors will be key in helping new car features work.

New Materials and Designs in Cars

Car makers always look for ways to make cars better. One way is by using new materials and smart designs for car wire connectors. These changes help make connectors last longer, weigh less, and be kinder to the planet.

Using Better Materials

Light and Strong Choices

Now, car makers use cool new stuff to make light but strong wire connectors. They use tough plastics and mixed metals that don't break easily. Lighter connectors help cars save gas and go faster. This change helps make cars that use less energy.

Caring for the Planet

Caring for Earth affects what materials are used in car wire connectors. Makers choose green options that don’t hurt nature much. They like things that can be recycled or have a small carbon footprint. This helps keep Earth clean while making sure cars stay safe and work well.

New Design Ideas

Easy-to-Change Designs

More people want wire connectors that are easy to change around in cars. These designs let you switch parts quickly, saving time and money when building cars. Flexible designs fit with the tricky wires in today’s tech-filled cars, helping everything work together smoothly.

Special Fit for Each Job

Making special wire connectors is important for different car parts like music systems or safety tools. Custom-made connectors work best, making driving better. By making special ones, makers meet the needs of electric and self-driving cars which need unique connectors to run right.

In short, new materials and designs change how car wire connectors are made. Using light, strong, and eco-friendly stuff helps meet what today’s car world needs. New design ideas like easy-change options make these parts work even better as cars get smarter.

New changes in car wire connectors have greatly changed the field. These new ideas make connections better and safer, fitting the needs of electric and self-driving cars. Makers use new materials and smart connectors to make them last long and check problems quickly.

In the future, more cool things are expected, like connectors that can check themselves and work better with electric cars. Keeping up with these tech changes is important for people who work with or love cars. As car technology grows, accepting these updates will help make cars run better and smarter.

See Also

Benefits of HFM Connectors for Automotive Applications

Significance of FAKRA Connectors in Car Technologies

Role of Fakra Connectors in Today's Automotive Designs