What Are the Key Features of Reliable Vehicle Connectors

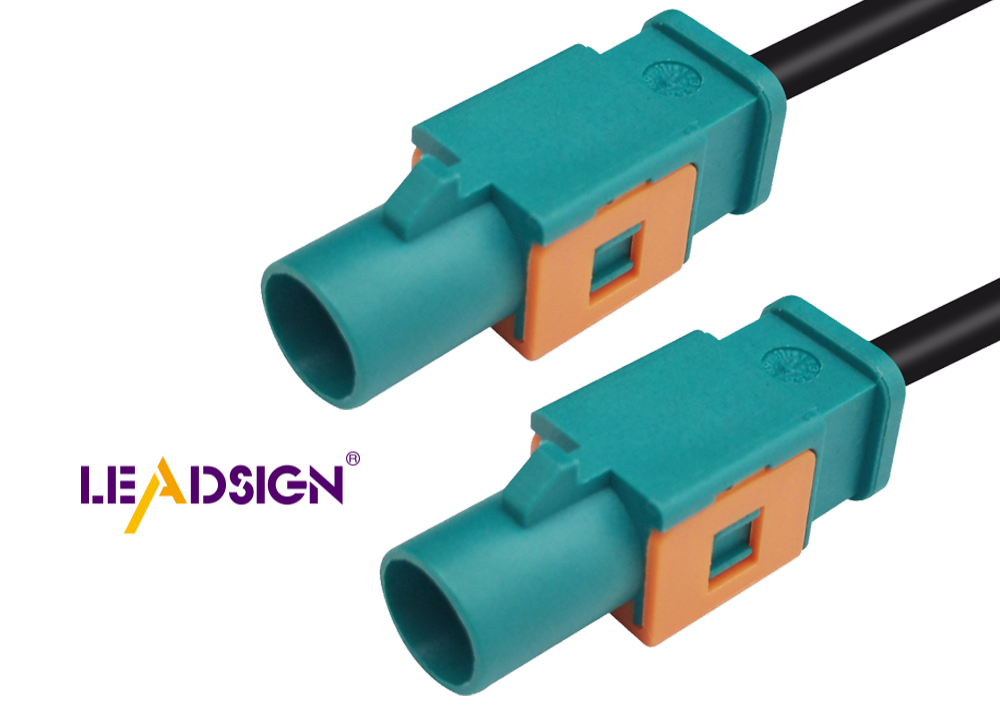

Reliable vehicle connectors are very important for car safety and performance. These connectors need to handle many challenges in cars. Important features are strength, weather resistance, good electrical work, easy setup, and fitting well. The car market needs connectors that work in tough conditions and stay connected. For example, car sensors need these vehicle connectors to work right. The number of pins in a connector can affect how often it breaks. This shows why strong design and good materials are important in cars.

Key Takeaways

Reliable vehicle connectors are essential for car safety and performance, requiring strength, weather resistance, and good electrical performance.

Choosing the right materials—metal for strength and conductivity or plastic for lightweight and corrosion resistance—can significantly impact the lifespan of connectors.

Sealed connectors are crucial for protecting against water and dust, making them ideal for harsh automotive environments.

Low electrical resistance in connectors ensures efficient power transfer, reducing energy loss and preventing overheating.

Easy installation features, such as no-tool setups and clear labeling, enhance user experience and reduce installation errors.

Standardized connectors promote compatibility across different car models, while customization options allow for specific needs, improving overall system performance.

Modular designs in connectors facilitate future upgrades and adaptations to new technologies, ensuring longevity and cost-effectiveness.

Durability and Material Quality

Importance of Strong Materials

Vehicle connectors need to be tough. They face hard conditions. Strong materials are a must. Automotive connectors use metal or plastic. Each has its own good points.

Metal vs. Plastic Connectors

Metal connectors are strong and conduct electricity well. They last long in tough places. But, they are heavy and cost more. Plastic connectors are light and cheap. They don't rust and work well in many automotive uses. Choosing metal or plastic depends on what the car needs.

How Material Quality Affects Lifespan

Good materials make automotive connectors last longer. Products from Forman Precision Industry Co., Ltd. handle heat and shaking well. This makes cars more reliable. Good materials cut down on fixes and save money. OEM Automotive Electrical Wiring Connectors show why strong materials stop rust and breaks.

Building Techniques

How automotive connectors are made is key to their strength. Right methods keep them working in different settings.

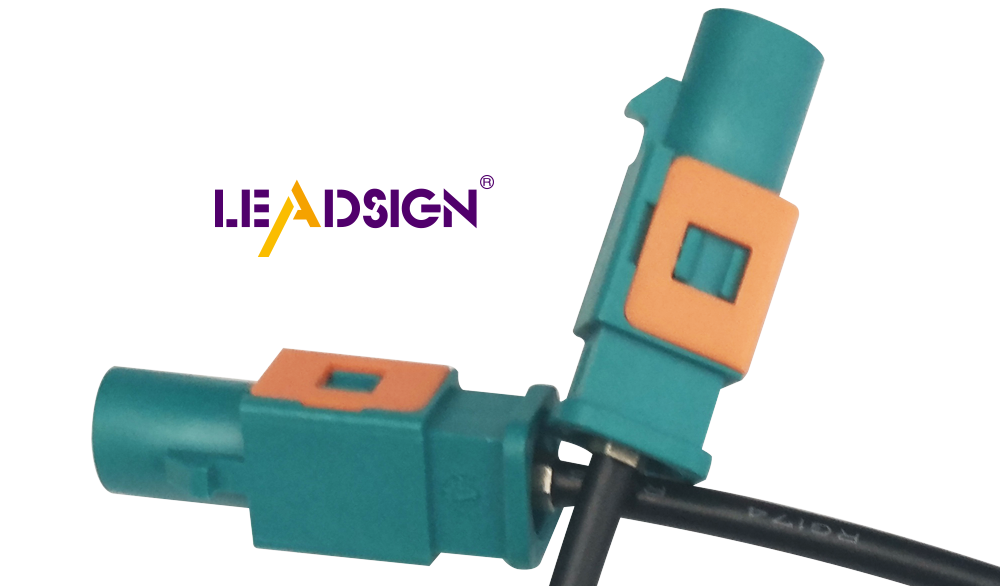

Sealed vs. Unsealed Connectors

Sealed connectors keep out water and dirt. They are needed in cars where harsh weather is common. Unsealed ones work in easier spots but lack protection. Hirose makes connectors for fast data and tough places, showing sealed ones are better.

Strengthening Methods

Strengthening makes connectors last longer. Extra locks or strong covers keep them connected. These ways stop them from coming apart and keep power flowing. Car Electrical Connectors by Forman Precision Industry Co., Ltd. show how to handle shaking and tough spots, making them last.

Environmental Resistance

Waterproofing Features

Vehicle connectors need to handle water and dust. Waterproofing helps them last longer and work well.

Sealing Technologies

Sealing stops water and rust, especially outside. Automotive-grade waterproof connectors use special seals like grommets and O-rings. These seals block water and dust, keeping connections safe. Using these seals, makers ensure connectors work in tough places.

IP Ratings and Their Significance

IP ratings show how well a connector blocks water and dust. Two numbers tell the protection level. The first is for solids, the second for liquids. An IP67 connector stops all dust and can be in water for a bit. Picking the right IP rating is key for car needs.

Temperature Tolerance

Connectors must handle hot and cold. This affects how long they last.

Materials Suitable for Extreme Temperatures

Connector materials must not break in heat or cold. Metals like stainless steel and some plastics work well. They keep connectors strong in any weather.

Testing for Thermal Resistance

Makers test connectors in hot and cold to see if they work. Passing these tests shows they are good for cars. This gives users confidence.

Electrical Performance

Vehicle connectors need to work well to keep cars safe. This part talks about how good connections help these connectors work better.

Keeping Connections Strong

Strong connections are key for car connectors to work right. They make sure signals go through without stopping, which is important for cars.

Contact Design and Materials

The way contacts are made affects how they work. Contacts from good stuff like copper last long and work well. They don't wear out or rust, making connectors last longer. A good contact design keeps it tight, so it doesn't come loose when the car moves.

Lowering Electrical Resistance

Low resistance helps power move easily. High resistance wastes energy and can make things hot. Makers use materials that resist less and make contact areas bigger. This helps connectors handle power without losing energy.

Signal Integrity

Signal integrity means signals stay clear and correct. It stops signals from getting messed up.

Blocking Interference

Cars have lots of interference that can mess up signals. Connectors have shields to block this noise. Shields keep signals clear, especially in sensitive parts.

Need for Good Insulation

Good insulation keeps signals safe. It stops short circuits and keeps out water and dust. Good insulation is used in connectors to work well in different places. This helps connectors send fast signals needed in today's cars.

Easy to Install and Fix

Simple Designs

Vehicle connectors should be easy to use. This makes putting them in simple. Many new connectors don't need tools to install. This helps more people use them. For example, push-in blocks let you connect wires without tools. This makes it faster and easier to set up.

"Some connectors, like push-in blocks, are easy to install. They need no tools," says a skilled car mechanic.

Clear labels and guides make using them better. Connectors with good labels and manuals help users install them right. This reduces mistakes and makes sure they work well. Always follow the guide for best results.

Keeping Them Working

Taking care of vehicle connectors is important. Easy access for repairs helps keep them working over time. Connectors with easy-to-reach parts make checking and fixing them quick. This is very helpful in cars where regular checks are needed for safety.

Making connectors easy to replace helps them last longer. Connectors that swap out easily save time and money. Barrier and screw-in blocks take more work to put in but are strong and easy to fix. This mix of easy setup and care keeps connectors working well for a long time.

Compatibility and Versatility

Working with Different Systems

Automotive connectors help different car parts work together. They connect complex systems so they work smoothly. This is important for new cars. Systems like engine control need accurate sensor data through safe connectors.

Standardization and Interchangeability

Standard automotive connectors can be swapped between systems. This lets makers use the same connector in many models. It cuts costs and makes fixing easier. Swappable connectors help mechanics replace broken parts without hunting for special ones.

Customization Choices

Standardization matters, but customization is also key. Automotive connectors can be made to fit special needs. Custom connectors fit unique car setups or special tasks. This boosts how well the car's systems work.

Fitting Different Car Models

Connectors that fit many car models are important. They let connectors work in small cars and big trucks.

Universal vs. Model-Specific Connectors

Universal connectors fit many car models, making them flexible. But, model-specific connectors meet a car's special needs better. Choosing between them depends on what the car needs and how custom it should be.

Future-Proofing with Modular Designs

Modular designs in automotive applications keep connectors up-to-date. They allow easy changes and upgrades. This keeps connectors useful as tech changes. Using modular connectors helps makers adapt to new tech without big changes, saving time and money.

Reliable car connectors are key for car safety and work. They connect different car parts to keep them running well. Good connectors help cars work better and cost less to fix. When picking connectors, think about how strong they are, if they can handle weather, and if they fit well. These things make sure the car works right and lasts long. Picking the best connectors makes sure all parts get power and data smoothly.

FAQ

What materials work best for car connectors?

Makers use metal and plastic for car connectors. Metal is strong and conducts electricity well. Plastic is light and doesn't rust. The choice depends on what the car needs.

How are sealed connectors different from unsealed ones?

Sealed connectors keep out water and dust, good for tough places. Unsealed ones work in easier spots but don't protect as much.

Why is the IP rating important for connectors?

The IP rating shows how well a connector blocks dust and water. A higher number means better protection. For example, IP67 stops all dust and can handle some water.

How do connectors keep signals clear?

Connectors keep signals clear with shields and good insulation. Shields block noise, and insulation stops short circuits and damage.

What makes a connector easy to put in?

Easy designs, like no-tool setups and clear labels, make connectors simple to install. These features cut down mistakes and speed up the process.

Are universal connectors better than specific ones?

Universal connectors fit many car models. Specific ones are made for certain needs. The choice depends on what the car needs.

How do makers test connectors for hot and cold?

Makers test connectors by putting them in very hot and cold places. This makes sure they work well in any weather.

How does material quality affect connector strength?

Good materials make connectors last longer by stopping wear and rust. This means less fixing and a longer life.

Can connectors be made for special uses?

Yes, makers can change connectors to fit special needs. This helps them work in unique car setups or do special jobs.

How do modular designs keep connectors up-to-date?

Modular designs let you easily change and upgrade connectors. This keeps them useful as new tech comes out, saving time and money.

See Also

Why FAKRA Connectors Are Essential for Automotive Systems

Fakra Connectors: A Key Component in Today's Vehicles

HFM Connectors: Transforming Connectivity in Automotive Technology

High-Speed Automotive Connectors: Boosting Data Transfer Efficiency