Key Developments in PCB Board to Wire Connectors

PCB board to wire connectors are important for modern electronics. They help parts communicate easily and work together smoothly. These connectors improve efficiency by speeding up data transfer and power flow. Their small size fits well with tiny electronic devices. This makes them essential in cars, healthcare tools, and gadgets we use daily. The market for these connectors may grow to $27.4 billion by 2026. Learning about new developments in this area helps create better designs and stay ahead in competition.

Key Takeaways

PCB board to wire connectors are essential for modern electronics, enabling efficient communication and power transfer in devices like cars and healthcare tools.

Innovations such as smaller designs, stronger materials, and automated production are enhancing the performance and durability of connectors.

Eco-friendly practices in connector manufacturing are becoming crucial, with a focus on recyclable materials and energy-saving methods.

The rise of IoT is driving the demand for smart connectors that can monitor performance and adapt to various applications.

Safety regulations are vital for modern connectors, ensuring they meet strict standards to prevent failures and enhance reliability.

Emerging markets present significant growth opportunities for connector manufacturers, driven by increasing technology adoption and renewable energy projects.

Understanding new PCB technologies and trends is key for companies to stay competitive and meet the evolving needs of the electronics industry.

Overview of PCB Board-to-Wire Connectors

Printed circuit boards (PCBs) need connectors to link parts together. Wire-to-board connectors are key in electronics, helping wires and PCBs connect easily. These connectors make assembly easier with flexible and removable links. They are useful in power systems, data transfer, and sensor setups.

Purpose and Functionality of PCB Board-to-Wire Connectors

Wire-to-board connectors move power or signals between different spots. They replace permanent wiring, making assembly more flexible. These connectors provide strong links but can be removed for repairs or upgrades.

There are different types like crimp connectors and terminal blocks. Crimp connectors hold wires tightly by squeezing them into place. Terminal blocks let wires slide in quickly and easily. Both types save time during assembly, helping industries like cars, phones, and gadgets.

Types of Connectors in PCBA Design Trends

New pcba design trends focus on small size and strength. This has led to many connector options:

Press-fit connectors: No soldering needed; they use pressure to connect parts.

Two-piece connectors: A plug fits into a socket for easy circuit connections.

IDC (Insulation Displacement Connectors): These cut through wire covers to connect faster.

These new ideas match the need for smaller, better devices in electronics today.

Challenges in Traditional Wire Harness Assembly

Old wire harness methods take lots of time and effort. Doing it by hand can cause mistakes and weak connections. Traditional ways also don’t adapt well to new designs.

Better connectors solve these problems by speeding up assembly and improving quality. For example, press-fit ones save time while IDC ones make wire connecting simple. These updates make assemblies work better and last longer.

Key Innovations in PCB Board-to-Wire Connectors

Smaller and Compact Designs

Modern gadgets need smaller, better-working parts. Making things tiny is now a big focus for pcb connectors. Engineers create connectors that take up little space but work well. These small designs are perfect for wearables, IoT devices, and high-density interconnect (HDI PCBs), where saving space matters most.

"Old PCB connectors just connected parts, but new ones handle more data faster."

This change has brought new ways to make pcb manufacturing easier. Tiny connectors fit perfectly into pcb design, saving space and improving how devices work. They also make gadgets lighter and easier to carry, which is key for future technology.

Stronger Materials for Better Durability

Using new materials and coatings has made printed circuit board connectors last longer. Makers now use tough plastics and metal alloys to handle harsh conditions. These materials stop damage, making them reliable in cars or planes.

Special coatings protect connectors from rust and electric problems. For example, gold or nickel coatings help them work better and last longer without breaking down. This shows how the industry works hard to build strong solutions for today’s electronics.

Automated Connector Production

Automation has changed how we do pcb manufacturing with smart systems. Robots and AI tools now make connectors quickly and accurately. Machines reduce mistakes, save time, and cut costs during production.

"New manufacturing methods focus on speed while keeping quality high."

Automation helps create hdi pcbs, which need careful attention because of their complex designs. Using advanced tools lets companies meet the rising demand for top-quality connectors in fields like healthcare, phones, and tech gadgets.

Better Electrical Performance in PCB Trends

Changes in printed circuit board connectors have improved how electricity flows. Older connectors only focused on simple links and couldn’t handle fast data or complex setups. New connectors now offer faster speeds, better reliability, and higher density.

A big step forward is using high-density interconnect (HDI) technology. These connectors are small but work very well. They reduce signal problems and keep parts connected smoothly. This makes them perfect for cars, phones, and communication devices.

Using new materials and coatings has also helped a lot. Coatings like gold or nickel make power flow easier and stop damage from rust or weather. This keeps the connectors working longer even in tough conditions.

Modern pcb design ideas focus on being exact and efficient. Engineers use smart methods to cut down electrical noise and keep signals clear. This is super important for hdi pcbs, which have tightly packed parts needing careful planning.

These improvements show how the pcb industry trends aim to create strong, useful solutions for many uses. They meet today’s needs while preparing for future tech advancements in electronics.

New Trends in PCB Board-to-Wire Connectors

IoT and Smart Connectors

IoT has changed how connectors work in electronics. Modern devices need connectors that are fast and reliable. Smart connectors now have sensors to check performance and conditions. These features make them great for factories, healthcare, and smart homes.

Small, high-density connectors are key for IoT gadgets. They save space but still work well. Flexible PCBs keep signals strong in small wire setups. This helps parts talk to each other easily, which is vital for IoT systems. As IoT grows, better connector designs will be needed.

Eco-Friendly Wire Harness Assembly

Electronics makers now focus on being eco-friendly. They use recyclable materials and energy-saving methods to help the planet. These steps aim to cut down on waste and support green ideas.

Wire harnesses now use biodegradable parts and lead-free soldering. These changes protect the environment while following strict rules. For example, electric car chargers use durable yet eco-friendly connectors. By going green, the industry supports a cleaner future.

Flexible and Modular Connector Designs

Flexible and modular connectors are becoming more popular now. They are easy to put together or take apart when needed. Modular ones can be adjusted for different uses.

Flexible connectors fit into tight spaces but still work well under stress. They are used in cars, planes, and other tough places. These new designs make assembly easier and more dependable too. The push for flexible designs shows the industry's focus on solving many needs efficiently.

Safety and Rules in Modern Connectors

Safety and rules are very important for modern connectors. As gadgets get more advanced, making sure connectors follow strict safety rules is a must. These rules keep users safe and make devices work better.

Modern connectors follow global safety rules like UL and RoHS. These rules ensure connectors are safe from harmful materials. They also check for fire resistance and good electrical insulation. New materials like PEEK and LCP are used because they resist heat, chemicals, and insulate well.

"Following safety rules helps connectors work safely in all conditions."

Connectors now have features to improve safety during use. Locks stop wires from disconnecting by accident. Crimp connections hold wires tightly in place for long use. Special designs prevent wrong connections, which is key for cars or factory machines.

Modern connectors also reduce signal problems like EMI (electromagnetic interference). Shields and coatings like nickel or gold stop signal issues. This keeps data moving smoothly between parts, even in high-speed setups.

Eco-friendly practices are part of connector design too. Companies now use recyclable materials and lead-free soldering to protect the planet. These steps meet green goals while following safety laws.

By focusing on safety and eco-rules, companies make reliable connectors that fit today’s needs while caring for the environment.

Uses of PCB Board-to-Wire Connectors

Car Electronics and Wiring Systems

Cars depend on these connectors to link electronic parts. They help systems like ADAS, infotainment, and EV chargers work well. These connectors handle strong power and fast data transfer, making them vital for cars.

Wiring in cars is easier with these connectors. They cut down assembly time and make connections stronger. For example, crimp connections and locks keep wires secure during tough drives. As electric and smart cars grow, better connectors will be needed.

"Electric cars and smart vehicles need strong, efficient connectors now."

Healthcare Tools and Medical Machines

In healthcare, these connectors power important devices like MRI machines. They also work in wearables that track health data. Their small size and good performance make them perfect for medical tools needing accuracy.

Medical devices need connectors that survive cleaning processes without breaking. Special materials like gold or nickel stop rusting and last longer. Flexible designs allow easy repairs or upgrades to keep devices updated.

IoT is growing in healthcare too. Smart tools like patient monitors send real-time data using these connectors. This shows how they improve patient care while keeping devices reliable.

Gadgets and PCBA Design Changes

Electronics like phones, laptops, or gaming consoles need small but powerful connectors. These parts help move data quickly while saving space inside gadgets.

New PCBA designs focus on smaller sizes and easy assembly. Press-fit or IDC connectors fit this trend by being simple to use yet dependable. This helps companies build products for different needs.

Smart home gadgets rely on these advanced connectors too. Wearables or IoT tools stay connected because of their design improvements. As more people use such devices, demand for better connector tech will grow.

"Smaller gadgets need tiny but reliable connector solutions today.

Industrial and Aerospace Uses

Factories and airplanes need strong connectors for tough conditions. These places often face heat, vibrations, and harsh chemicals. PCB board-to-wire connectors help keep things connected and working well.

In factories, these connectors power robots and big machines. They move power and data quickly to keep work smooth. Wire harnesses make wiring simpler, saving time during setup. Flexible designs also make fixing or upgrading easier.

Airplanes need connectors that handle high altitudes and stress. Lightweight materials like special metals make planes lighter but strong. Safety rules ensure these connectors stay reliable in important tasks. Features like crimping and locks stop wires from coming loose.

IoT has made these connectors even more useful in factories and planes. Smart sensors use them to send data fast and get power easily. For example, IoT systems in factories or planes need good connectors for real-time updates.

"As technology grows smarter, better connectors are needed everywhere."

PCB board-to-wire connectors are key for industries today. Their small size and strength help meet new challenges in factories and airplanes.

Future Outlook for PCB Board-to-Wire Connectors

Predictions for Upcoming Innovations in Connectors

The future of connectors will bring exciting new changes. Engineers are working on next-generation manufacturing to make faster and more efficient connectors. These updates will help with IoT, self-driving cars, and advanced robots.

Smaller devices need tiny connectors that still work well. Flexible and modular designs will become popular for different applications. Smart features like self-checking abilities will change how connectors work in important systems.

"Connectors are improving in size, smarts, strength, and flexibility."

Electric vehicles need better charging connectors for higher power levels. These must be safe, reliable, and follow strict rules. Strong materials that last longer in tough conditions will also be explored.

Challenges in the PCB Industry Trends

The pcb industry trends show some big challenges ahead. One issue is keeping up with stricter safety and eco-friendly rules. These rules can slow down product creation and market launches.

Another problem is the growing complexity of printed circuit board designs. Small parts with many layers need precise connectors to work well. Making these requires advanced tools and skilled workers, which raises costs.

Supply chain problems also cause delays. More people want connectors, but material shortages can slow production down. Companies must plan better to avoid these issues.

"Facing PCB challenges needs smart ideas and teamwork."

Opportunities for Growth in Emerging Markets

New markets offer great chances for connector makers to grow. Places like Asia-Pacific, Latin America, and Africa are using more tech quickly. This increases demand for wire harness assembly in cars, phones, and gadgets.

Renewable energy projects also need strong connectors. Solar panels or wind turbines rely on them to move power smoothly. The rise of IoT in smart cities or farms creates a need for special connector designs too.

"Emerging markets drive both innovation and growth in the connector world."

Investments like 5G networks or EV chargers boost connector demand even more. Companies that understand local needs can grow fast here by teaming up with regional partners.

New PCB board-to-wire connectors have changed modern electronics greatly. These updates make devices work better, last longer, and adapt easily. They are very important in cars, healthcare tools, and gadgets we use daily. Improved wire harness designs now help build products faster and more reliably. Learning about new PCB technologies helps create smarter solutions for the future. As people want greener and smarter systems, connectors will stay key in improving electronics everywhere.

FAQ

What are PCB board-to-wire connectors?

PCB board-to-wire connectors link wires to circuit boards. They help parts share power and data smoothly. These connectors are used in cars, planes, gadgets, and communication tools.

Why are PCB connectors important in modern electronics?

PCB connectors make electronics smaller and easier to fix. They simplify building devices and allow easy upgrades. You’ll find them in phones, laptops, machines, and even space tech.

What industries use PCB board-to-wire connectors?

These connectors are used in many fields:

Automotive electronics: For systems like car sensors and entertainment.

Medical devices: Powering health tools like scanners or fitness trackers.

Aerospace and defense: Working well under tough conditions.

Consumer electronics: Helping make small gadgets like smartphones.

Telecommunications: Supporting fast data transfer for networks.

How do PCB connectors support miniaturization in electronics?

PCB connectors help make tiny but powerful devices. Their small size works well for wearables or smart home gadgets. This lets companies build light products without losing quality.

What types of PCB board-to-wire connectors are available?

There are different kinds of these connectors:

Crimp connectors: Hold wires tightly for strong links.

Press-fit connectors: Use pressure instead of soldering to connect.

IDC connectors: Quickly connect wires by cutting through their covers.

Each type fits specific needs across industries.

How do PCB connectors enhance durability?

Strong materials like plastics and metals make these last longer. Coatings such as gold stop rusting and improve performance. This makes them reliable for cars or airplanes.

Are PCB connectors eco-friendly?

Yes, some now use recyclable materials to protect the planet. Lead-free designs also follow green rules while reducing waste.

What role do PCB connectors play in IoT devices?

They keep IoT gadgets connected easily with their tiny size. Smart versions can check how they work, making them great for homes or factories.

How do PCB connectors improve safety?

Modern designs follow strict safety rules to prevent problems. Locks keep wires secure while special features avoid wrong setups. These ensure safe use in cars or medical tools.

What is the future of PCB board-to-wire connectors?

The future includes smarter designs that adapt better to needs. Eco-friendly materials, self-checking features, and new methods will lead to better products for growing technology demands.

See Also

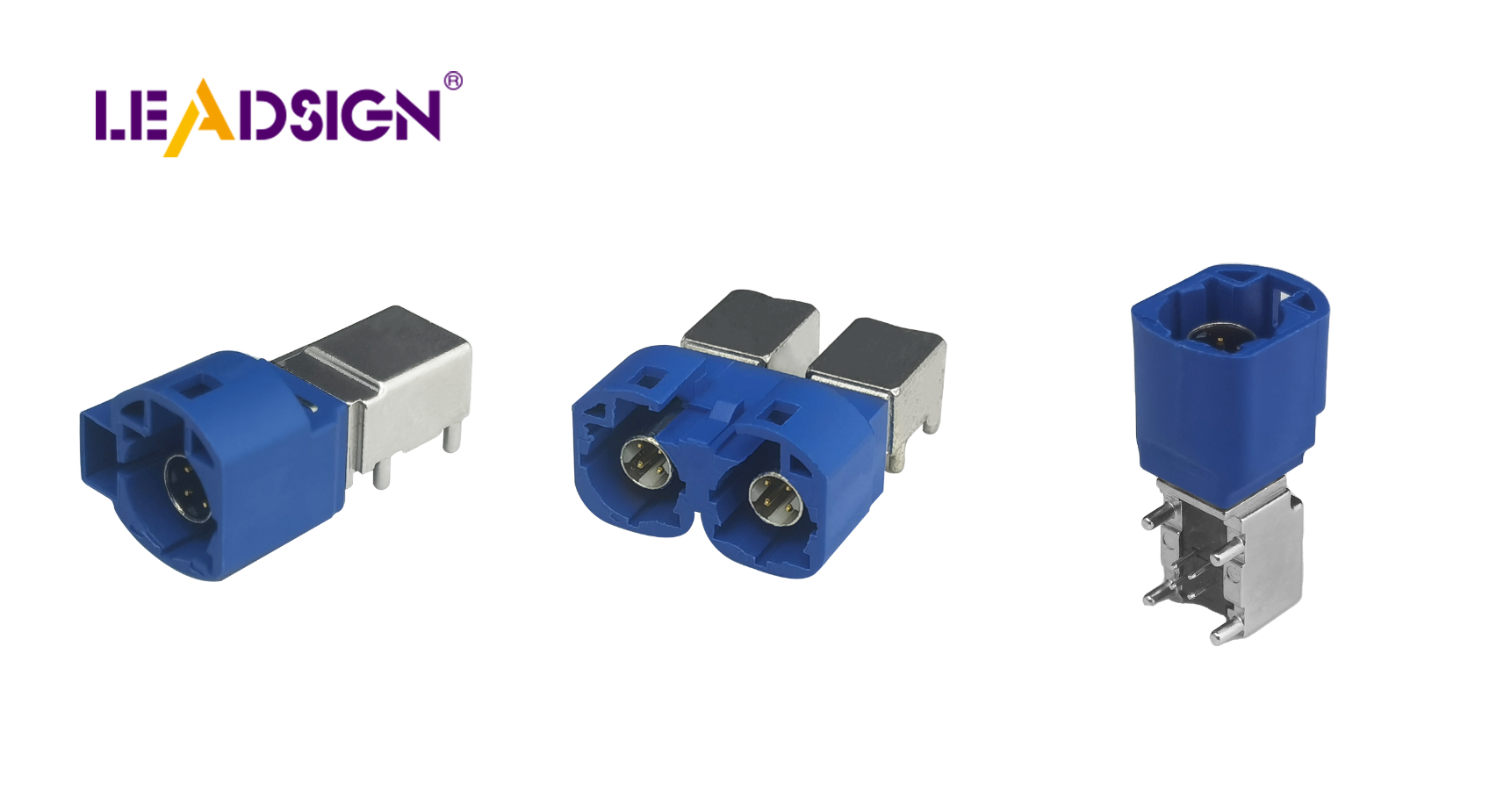

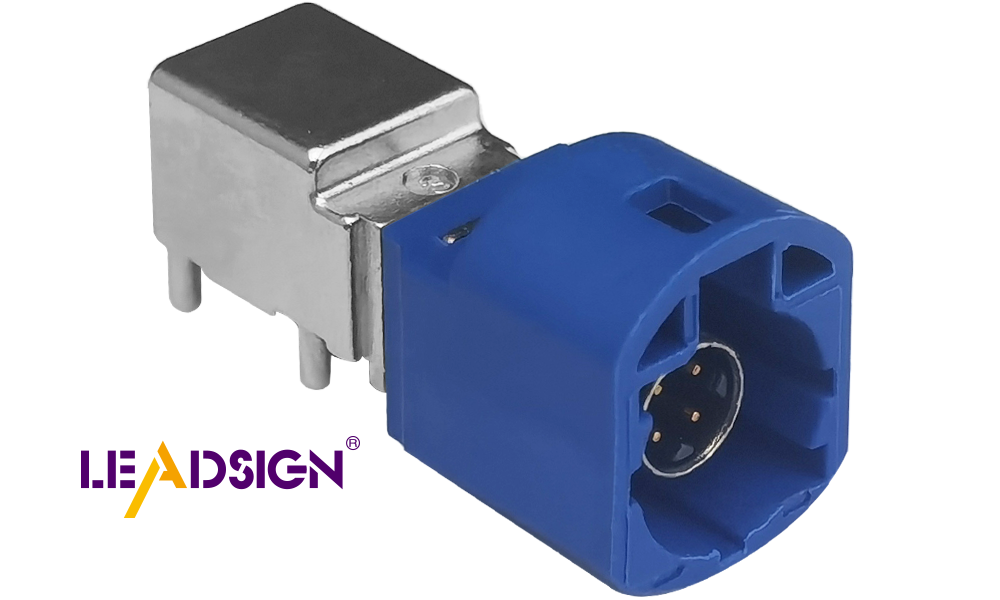

Exploring FAKRA Connectors for Enhanced Automotive PCB Performance

Key Benefits of FAKRA Connectors in Automotive Systems

Why FAKRA Connectors Are Crucial for Automotive Communication

FAKRA PCB Mount Connectors: Benefits for Automotive and RF Use