Key Considerations for Choosing Electrical Connectors

Choosing the right types of connectors electrical is crucial for ensuring the safety and efficiency of your systems. Connectors play a significant role in the performance and reliability of your setup. Selecting the appropriate connector reduces the likelihood of issues arising from exposed wires or incorrect wire terminations. There are various types of connectors, such as wire-to-wire and board-to-board, each with its specific applications and advantages. Understanding these types helps you make informed decisions, ultimately enhancing the longevity and functionality of your systems.

Key Takeaways

Choosing the right electrical connector is essential for system safety and efficiency, reducing the risk of failures.

Understand the different types of connectors—wire-to-wire, wire-to-board, and board-to-board—to select the best fit for your application.

Always check the current rating of connectors to ensure they can handle the required load, preventing overheating and potential hazards.

Consider the size and shape of connectors to ensure they fit your device's design and space constraints without compromising functionality.

Prioritize reliability by selecting connectors made from high-quality materials that can withstand environmental stresses.

Look for connectors with proper environmental sealing to protect against water, dust, and dirt, ensuring long-term performance.

Consult with experts and conduct thorough testing to validate connector choices, minimizing risks and enhancing system reliability.

Types of Connectors Electrical and Their Uses

Knowing different connectors helps you pick the right one. Each type has special uses and benefits.

Wire-to-Wire Connectors

Wire-to-wire connectors are important in cars and factories. They keep wires connected safely, which is key for system strength.

Applications in Automotive and Industrial Settings

In cars, wire-to-wire connectors join parts like sensors. They handle tough conditions like shaking and heat changes. In factories, these connectors link machines, ensuring they work well.

Common Types and Their Features

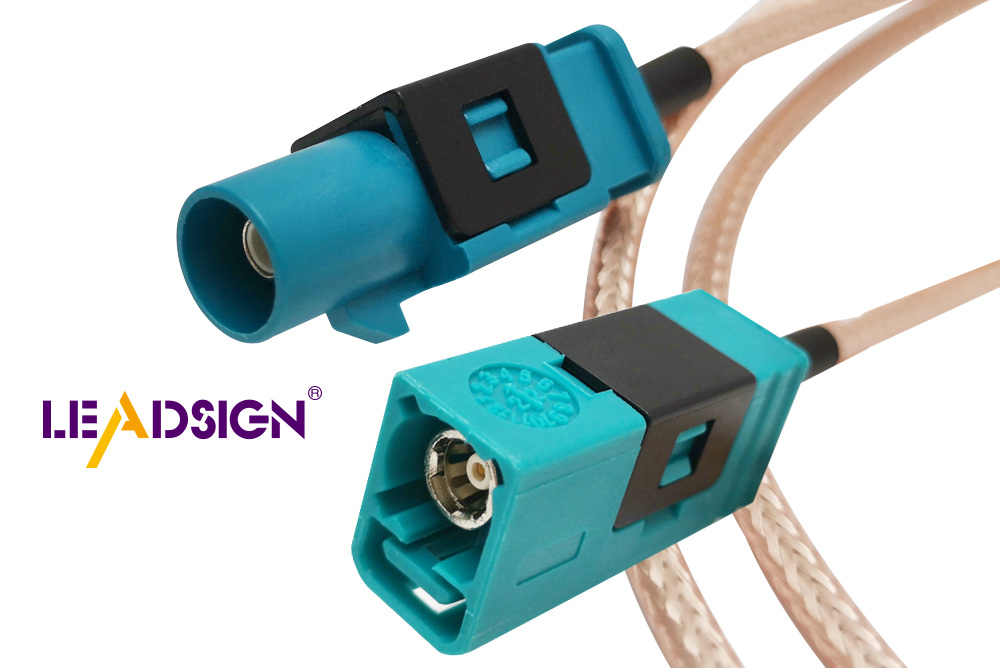

Common wire-to-wire connectors include FAKRA connectors. These are used in cars for things like GPS. They have systems to stop wrong use and lock securely. They are strong and last long, perfect for tough places.

Wire-to-Board Connectors

Wire-to-board connectors are common in gadgets and home devices. They join wires to circuit boards, helping data and power move well.

Uses in Consumer Electronics and Appliances

In gadgets, wire-to-board connectors link parts like screens. In home devices, they connect panels to circuits. These connectors help things work smoothly and last longer.

Variations and Their Specific Benefits

Wire-to-board connectors come in types like USB Type-B connectors. These connect things like printers to computers. They fit well and move data safely.

Board-to-Board Connectors

Board-to-board connectors are key in computers and phones. They join circuit boards, helping parts talk to each other.

Importance in Computer and Telecommunications Equipment

In computers, board-to-board connectors link main boards to cards, moving data well. In phones, they join modules, helping communication and data work smoothly.

Different Configurations and Their Applications

Board-to-board connectors include Backplane connectors. They connect many boards together, lining up pins for data flow. These are needed in big systems where boards must talk well.

By knowing these connectors, you can choose better, making systems work and last longer.

Key Things to Think About for Picking Connectors

When picking connectors for your electric systems, think about a few things. These help you choose the right connector for your needs, making them work better and safer.

Current Rating

Knowing the current rating is important. This tells how much current the connector can safely handle. You need to know what your device needs to avoid problems.

Knowing What Your Device Needs

Every device needs different current levels. Big devices need connectors with high current ratings. Check your device's needs to find the right connector. This stops the connector from getting too hot or breaking.

Problems with Wrong Current Rating

Using the wrong current rating can cause big issues. If it's too low, the connector might get too hot and break or start a fire. If it's too high, it might cost more than needed. Picking the right rating keeps things safe and saves money.

Size and Shape

The size and shape of a connector matter for your device. Think about space limits and design when choosing connectors.

Space Limits and Design

In small devices, space limits are important. Pick connectors that fit without losing function. Small connectors might be needed for tight spots but must still work well.

Effect on Setup and Fixing

Size and shape affect setup and fixing. Big connectors are easier to handle but might mess up your system's layout. Small ones need careful setup. Balance these for easy use and fixing.

Reliability and Strength

The reliability and strength of a connector show how well it works over time. Choose connectors made from good materials and strong build.

Why Good Materials Matter

Connectors from good materials last longer and work better. Look for strong connectors that handle stress and wear. This keeps them reliable for a long time.

Checking Tests and Approvals

Good connectors have passed tests and have approvals. Look for standard approvals that show the connector works well. This ensures it will work right in your device.

By thinking about these key things, you can pick the best connectors for your systems. This makes sure your connectors meet the needed electric and mechanical needs, giving a strong and good connection.

Environmental Sealing

When picking an electric connector, think about sealing. This helps connectors handle tough conditions and work well.

Protection from Water, Dust, and Dirt

Connectors can get wet or dusty. These things can harm connectors and mess up connections. To stop this, choose connectors with good seals. This keeps systems working well and lasting longer. For instance, heat shrink connectors seal tightly, protecting from bad weather.

Sealing Methods and How They Work

Different seals make connectors last longer. Some use rubber rings to block dirt. Others use special stuff to keep out water and dust. Each seal has its own perks. Check these choices for what you need. Good seals help connectors work in hard places.

Cost Considerations

Cost is important when picking connectors. You need to balance cost with how well they work.

Balancing Cost with How Well They Work

Think about cost versus how well connectors work. Cheap ones save money but might break. Good connectors last longer. This balance helps you get good performance without spending too much.

Long-term Costs of Connector Choices

Think about long-term costs of connectors. Good ones cost more at first but need less fixing. They also cut down on downtime, saving money later. By picking strong connectors, you keep things running and avoid big repair bills.

Practical Tips for Picking the Right Electric Connector

Choosing the right electrical terminal is very important. It helps keep your systems safe and working well. Here are some easy tips to help you choose the best one.

Checking What You Need

First, know what you need for your connector.

Finding Out What You Need

Think about what your system needs. Look at things like how hot or cold it gets where you use the connector. If it gets really hot or cold, pick connectors that can handle it. This way, your wires and cables work well without breaking.

Matching Connector Features to Needs

Make sure the connector has what your system needs. If you have special wires, the connector should protect them. It might need to keep out water and dust. This helps your wires last longer and stay safe.

Asking Experts

Getting help from experts is really useful, especially for tricky systems.

Why Expert Help is Important

Experts know a lot about connectors. They can tell you which ones are best for you. Their advice stops mistakes and keeps your system working well.

Where to Find Expert Help

You can find experts in many places. Try industry forums, workshops, or talk to professional consultants. These places have people who can help you pick the right connectors.

Testing and Trying Out

Testing is key to making sure the connector works for you.

Why Testing Connectors is Good

Testing shows how connectors work in real life. It finds problems before you use them for real. This makes sure they meet standards and work as they should.

Steps for Good Testing

Make a Prototype: Build a small version of your system with the connectors.

Test in Real Life: Try it out in real conditions.

Check and Fix: See how it works and make changes if needed.

By doing these steps, you make sure the connectors are good for your system. This way, you lower risks and make your system work better.

Choosing the right connector is very important for safety. It helps your system work well and avoids expensive fixes. Think about things like current rating and sealing. Expert advice can help you pick the best connector. The right one makes your system smaller and easier to use. Focus on reliability to stop problems. This way, your system lasts longer and works better, keeping everything running smoothly.

FAQ

What are electrical terminals?

Electrical terminals connect wires to devices or other wires. They make sure connections are safe and work well. You see them in things like home gadgets and big machines.

Why is choosing the right electrical terminal important?

Picking the right terminal keeps systems safe and working. The right one connects well, stopping problems and costly fixes. It also helps your setup last longer and work better.

What types of electrical terminals are available?

There are many kinds of terminals for different jobs. Common ones are ring, spade, and bullet terminals. Each type is good for certain tasks, like easy setup or strong connections.

How do I determine the right size of an electrical terminal?

To pick the right size, check the wire size and use. The terminal should fit the wire well, not too tight or loose. Right sizing keeps connections safe and stops problems.

What factors should I consider when selecting electrical terminals?

Think about current rating, material, and weather when picking terminals. These affect how well they work and last. Make sure they match your system's needs for best results.

Can I use any electrical terminal for high-voltage applications?

No, not all terminals work for high voltage. Pick ones made for high voltage to stay safe and avoid problems. Always check what the terminal can handle before using it.

How does the shape of an electrical terminal affect its use?

The shape affects how you install and use terminals. Ring terminals hold tight, while spade ones are easy to remove. Choose the shape that fits your project best.

Are there specific electrical terminals for harsh environments?

Yes, some terminals are for tough places. They have coatings or materials that fight rust, water, and heat. Using these keeps them working well in hard spots.

How can I ensure the longevity of my electrical terminals?

To make terminals last, use good materials and install them right. Clean and check them often to stop wear and keep them working long.

Where can I find expert advice on selecting electrical terminals?

Get advice from pros, online groups, or special classes. These give tips and help you pick the best terminals for your needs.

See Also

Understanding The Significance Of FAKRA Connectors

Advantages Of FAKRA Connectors For PCB In Automotive

Why FAKRA PCB Connectors Are Essential For Automotive