Key Automotive Wiring Connector Types for Modern Vehicles

Automotive wiring connector types are crucial components in cars, facilitating communication and power distribution. As automotive technology advances, the demand for specialized connectors continues to increase. The automotive wiring connector market is projected to experience a 5.8% annual growth rate until 2026, underscoring their significance in vehicle systems. These connectors play a vital role in various car systems such as safety and entertainment, enhancing overall performance and longevity. They represent essential elements within the modern automotive industry.

Common Types of Automotive Wiring Connectors

Modern cars use many automotive wiring connector types. They help with communication and power sharing. These connectors are key for car systems to work well.

Blade Connectors

Blade connectors are common in cars because they are simple and work well.

Uses in car systems

Blade connectors are used in lights, fuse boxes, and other electric parts. They connect quickly and safely, which is great when you need to unplug them often.

Good points and limits

Blade connectors have good points:

Easy to use: Simple to plug in or out.

Flexible: Works in many places.

But they also have limits:

Low current limit: Not good for high-power needs.

Can rust: Needs sealing to keep water out.

Pin Connectors

Pin connectors are important for electronic control units (ECUs) in cars.

Role in ECUs

These connectors help the ECU talk to other car parts. They make sure signals go right so electronics work together well.

Strong and reliable features

Pin connectors are built strong:

Tough build: Handles tough car conditions.

Steady links: Keeps signals steady.

Their strength makes them vital for modern automotive wiring connector types.

Coaxial Connectors

Coaxial connectors are key for talking systems in cars. Coaxial connectors are key

Part in talking systems

These connectors handle fast signals, needed for music, maps, and driver help systems. They send data fast, which is important for self-driving tech.

Setup tips

When setting up coaxial connectors, remember:

Right fit: Keeps signal clear.

Tight hold: Stops unhooking from shaking.

Coaxial connectors show how advanced automotive wiring connector types are, meeting the need for fast data sending in cars.

Standards and Classifications

ISO Standards

Why they matter in cars

ISO rules are very important for car parts. They make sure connectors are safe and good quality. When companies follow these rules, their connectors work well in different situations. This is crucial because cars need strong connections to run properly.

Main connector rules

ISO 10487 is a big rule for car connectors. It splits them into four groups: multi-pin sealed, terminal, wire-to-board, and others. These groups help make sure connectors fit right and work well. By using these rules, car connectors can handle modern vehicle needs.

SAE Classifications

What the classifications mean

The Society of Automotive Engineers (SAE) gives more details about car connectors. They look at what they're made of and how they work. This helps pick the best connector for each job, making car systems better.

How they affect picking connectors

SAE rules help choose the right car connectors. They give clear details so engineers know which ones to use. This makes sure the connectors can handle things like heat changes and shaking. Cars with SAE-approved connectors work better and last longer.

Fixing Common Problems

Modern cars use many automotive wiring connector types. But, these connectors can have problems that affect how they work. Knowing these problems helps keep cars running well.

Connector Problems

Connector problems can stop car systems from working. Finding out why and fixing them keeps things reliable.

Causes and Fixes

Many things cause connector problems:

Mating Force: Too much force can break connectors.

Moisture and Corrosion: Water causes rust, making connections weak.

Fretting: Shaking causes wear, leading to bad contact.

To fix these, use connector grease. It cuts down friction and stops water damage. Checking often helps find issues early.

Tips for Care

Taking care of connectors is easy but important:

Clean Often: Remove dirt to keep connections clear.

Seal Right: Use seals to block weather effects.

Install Correctly: Follow maker's rules to avoid harm.

These steps help automotive wiring connector types last longer and work well.

Matching Issues

Problems happen when connectors don't fit the car's system right. Solving these is key for smooth working.

Spotting Matching Problems

Mismatch happens because of:

Wrong Connectors: Non-OEM ones might not fit or work well.

Different Standards: Different rules can cause mismatches.

Buying good OEM connectors makes sure they fit right. They match the car's design for good performance.

Solutions for Smooth Working

For smooth working:

Use OEM Connectors: They ensure fit and best performance.

Check Maker’s Advice: Follow tips on connector types and specs.

By fixing these issues, automotive wiring connector types support the car’s complex systems well.

Understanding different car wiring connectors is important. They help signals move smoothly in cars. Connectors like blade, pin, and coaxial types are key. They keep communication and power flowing well.

Picking the right connectors, especially OEM ones, is crucial. They fit perfectly and work reliably. This keeps electrical links strong, which helps the car run better. Choosing good connectors makes the car's electric system last longer and work well. This leads to safer and smoother driving.

See Also

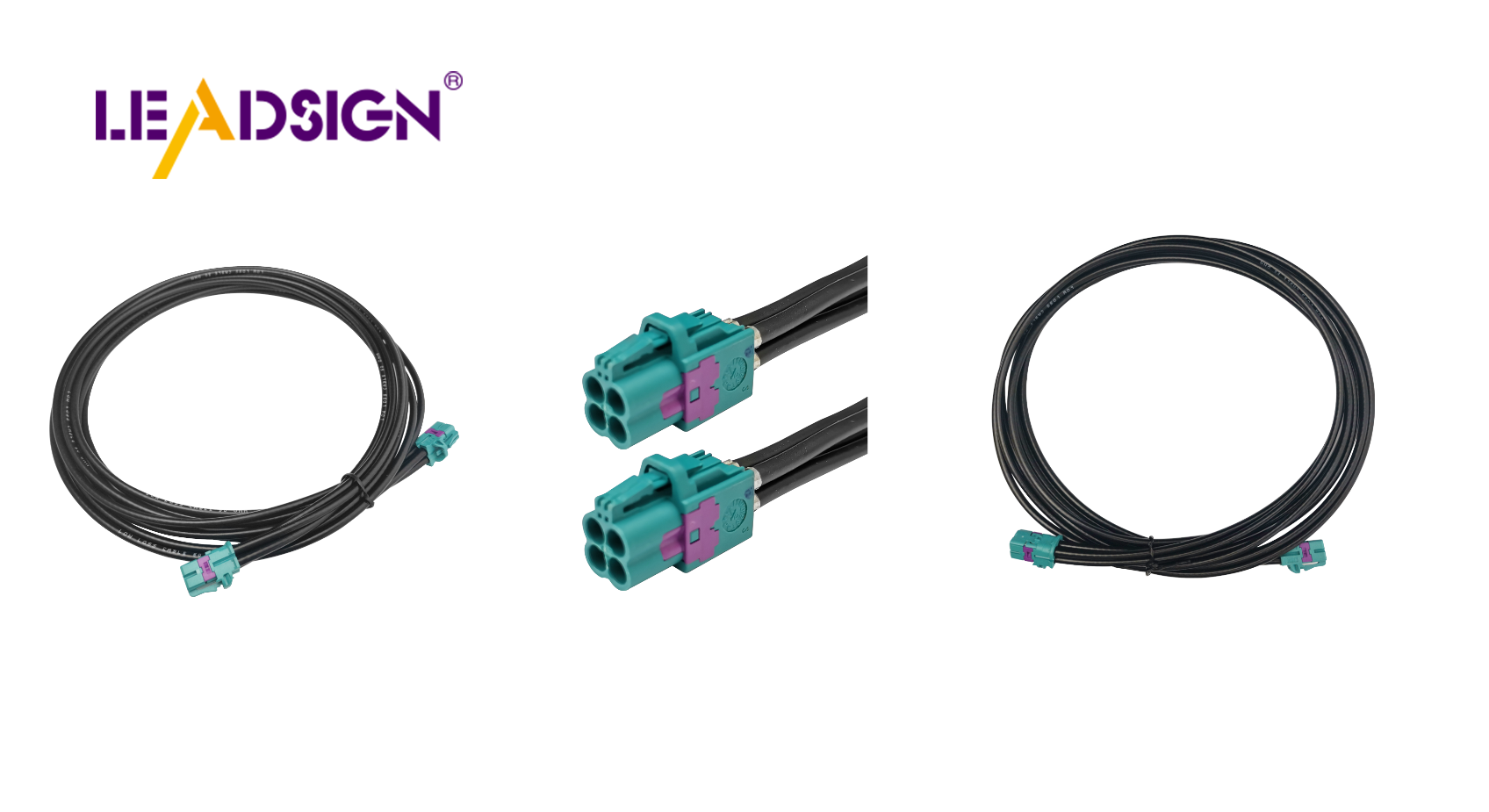

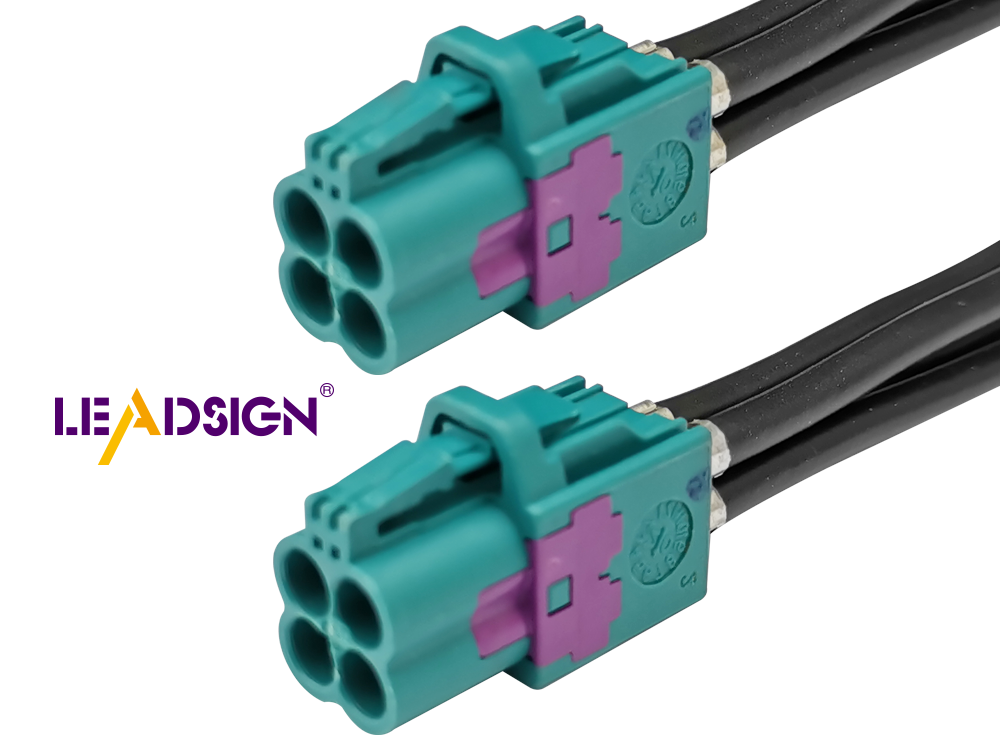

The Significance of Fakra Auto Connectors in Contemporary Cars

Fundamentals of HSD Connectors in Auto Sector

Enhancing Auto Data Transfer: Advanced Connectors and Cables