What Are the Key Automotive Wiring Connector Types?

Understanding automotive wiring connector types is crucial for repairing vehicles. These connectors play a vital role in ensuring the proper functioning of all electrical components in a car. They establish connections between various elements of the vehicle's electrical system, facilitating the efficient transmission of power and signals. With a variety of connector types available, it can be overwhelming to choose the right one. From blade connectors to pin connectors, each type serves a specific purpose, contributing to the reliable operation of modern vehicles.

Basics of Automotive Wiring Connectors

Definition and Purpose

What are wiring connectors?

Wiring connectors are key parts in car electrical systems. They link wires and cables, making sure connections stay strong. These connectors help electricity and signals move between vehicle parts. Without them, the system could break down and cause problems.

Why are they essential in vehicles?

Wiring connectors keep a car's electrical system working well. They make sure power and signals go where needed without stopping. For example, the Ignition Switch Connector helps start the engine. A good connector stops issues like short circuits or losing power, which can hurt how a car runs.

General Characteristics

Materials used

Car wiring connectors use tough materials to handle rough conditions. Makers often choose metals like copper or brass for good flow of electricity. Plastic or rubber covers protect from water and heat. These materials make sure they last long in different places.

Common features and specifications

Wiring connectors have special features to meet car standards:

Secure locking mechanisms: Stop accidental unhooking.

Weather resistance: Guard against water and temperature shifts.

Compatibility: Fit with many wire sizes and types.

Problems like Connector Issues happen when these aren’t met. Tests show issues like loose links or rusting. Fixing these problems makes sure connectors work well, helping the car run smoothly.

Types of Automotive Wiring Connectors

Knowing different automotive wiring connector types helps pick the right one. Each type has special features and jobs in car electrical systems.

Blade Connectors

What they are and how they're used

Blade connectors, or spade connectors, have a flat metal piece. This fits into a matching slot. They're often used to link wires to parts like switches. Their design makes connecting easy and fast, good for when you need to unplug often.

Good and bad points

Good Points:

Simple to plug in and out.

Easy to find and cheap.

Works for low to medium power needs.

Bad Points:

Can get loose over time, causing weak links.

Not great for places with lots of shaking because they might come apart.

Pin Connectors

What they are and how they're used

Pin connectors have pins that go into sockets. They're used in car wiring harnesses for many wires in small spaces. These give strong connections, perfect for important systems like engine controls.

Good and bad points

Good Points:

Give strong, steady links.

Good for tight wiring spots.

Handle more power than blade connectors.

Bad Points:

Harder to put in and take out.

Cost more than simpler connectors.

Other Automotive Wiring Connector Types

Bullet Connectors

Bullet connectors are round and quick to connect. They're used in car lights where you need to unplug often. They fit tightly, so they don't easily disconnect by accident.

Terminal Blocks

Terminal blocks join many wires safely. They're found in car wiring harnesses to sort connections. They let you connect or disconnect wires easily, great for tricky wiring setups.

Note: Problems with connectors can happen during tests when building cars. Issues like loose links or rust can cause failures. Fixing these early makes sure the automotive wiring connector types work well.

Uses and How to Install

Where They Are Used

In engines

Automotive wiring connectors are important for engines. They join sensors and control parts, helping the engine work well. For example, they link the engine control module (ECM) to sensors checking temperature and pressure. This helps the ECM make the engine run better and cleaner.

In lights

In lighting systems, connectors give power to headlights and taillights. They keep connections strong even when the car shakes or gets wet. Good connectors stop lights from flickering, making night driving safer.

How to Install Them

Tools you need

To put in automotive wiring connectors, you need special tools:

Wire strippers: Take off wire covers without harm.

Crimping tools: Press wires into connectors tightly.

Screwdrivers: Turn screws on blocks or other parts.

Multimeter: Check if electricity flows right.

Steps to follow

Get wires ready: Strip 1/4 inch of cover from wire ends. Make sure wires are clean.

Pick a connector: Choose one that fits your job and wire size. It must match the car's system.

Put on the connector: Slide bare wire into it. Use crimping tool to hold it tight.

Check it works: Use multimeter for good flow of electricity with no breaks.

Make it secure: Tighten screws if needed so it stays put during movement.

Look over your work: Check for any damage or wrong setup. Ensure everything is in place.

By doing these steps, you can make sure connections in cars work well and safely. Right installation stops loose links or electric problems, keeping cars running smoothly.

Common Problems and Fixes

Usual Issues

Rust

Rust often harms car wiring connectors, especially where it's wet. It happens when metal parts react with air or water, making rust. This rust can stop electricity from flowing right, causing problems in the car's electrical system. Checking connectors often for rust helps keep them working well.

Loose Links

Loose links are another usual problem in car wiring. They happen when connectors don't fit tightly, causing weak electrical contact. This can make lights flicker or electronics act weird. Making sure connectors are tight during setup can stop these issues.

Fixing Tips

Finding Problems

To find problems with car wiring connectors, start by looking at them for wear, rust, or damage. A multimeter helps check if electricity flows right through the connectors. Listen for strange sounds or watch for odd behavior in electronics to spot connector troubles.

Fixes and Care

Fixing connector problems needs a few steps:

Clean Rusty Connectors: Use a wire brush or sandpaper to clean rust off rusty connectors. Putting on a rust blocker stops more rust later.

Tighten Loose Links: Make sure all connectors fit tight. Use the right tools to secure them so they don't move and disconnect.

Swap Bad Connectors: If a connector is very worn or broken, swapping it with a new one makes sure it works well.

Regular Checks: Plan regular checks of the car's electrical system. This careful approach finds and fixes possible problems before they get worse.

By using these fixing tips, you can keep car wiring connectors working well, ensuring the car's electrical system runs smoothly.

Knowing different car wiring connectors is important to keep cars working. Each type, like blade or pin, helps make sure strong connections are strong. When picking connectors, choose ones that fit well and are good quality. This makes the car's electrical system work better and safer.

See Also

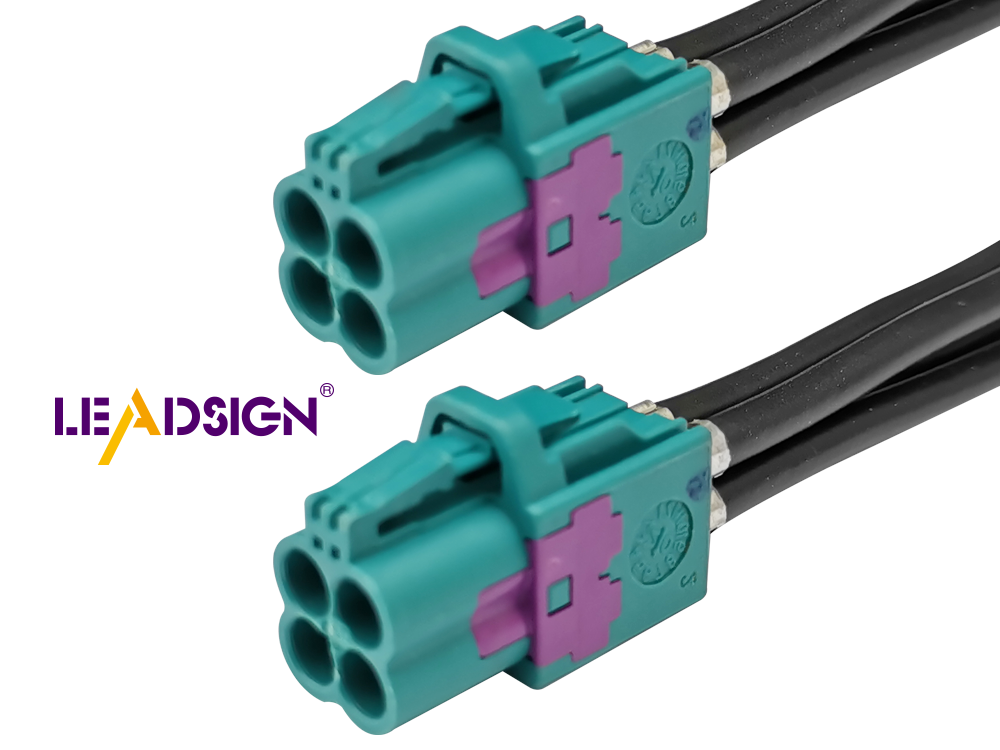

Exploring the Fundamentals of HSD Connectors in Automotive

Understanding the Significance of Fakra Connectors in Modern Cars

The Significance of FAKRA Connectors in Auto Uses