Installing Automotive Plugs and Connectors: A Step-by-Step Guide

Vehicle connectors are very important for your car to work well. They send electrical signals to different parts of the car, helping it run smoothly. Installing these vehicle connectors properly prevents problems like loose wires, rust, and excessive heat. When you install them correctly, your car's electrical system becomes safer and more reliable. This enhances your car's performance and provides you with a sense of achievement. Keep in mind, a good connection now means fewer issues later.

Key Takeaways

Proper installation of automotive connectors enhances your car's electrical system, making it safer and more reliable.

Always disconnect the battery before starting any electrical work to prevent shocks and short circuits.

Choose the right connectors by consulting your car's manual and opting for OEM connectors for the best fit and performance.

Use essential tools like crimping tools and multimeters to ensure secure connections and check for electrical flow.

Regularly inspect and maintain your connectors to prevent issues like rust and loose connections, ensuring long-term reliability.

Wearing safety gear, such as gloves and safety glasses, is crucial to protect yourself while working on automotive electrical systems.

Getting Ready and Staying Safe

Before you start putting in automotive plugs and connectors, it's important to get ready and think about safety. This helps make the job easy and keeps you safe from mistakes or accidents.

Tools You Need

To put in automotive connectors right, you need some important tools. These tools help you work well and make sure everything fits tightly.

Basic Tools

Screwdrivers: Use these to loosen or tighten screws on connectors.

Pliers: Good for holding and twisting wires.

Wire Strippers: Needed to take off wire covers without breaking them.

Special Electrical Tools

Crimping Tool: This tool is key for joining connectors to wires. It squeezes them together tightly. Pick one with different size settings for strong fits.

Multimeter: Use this to check if electrical parts are working right.

Staying Safe

Safety is most important when working with car electrical parts. Being careful keeps you and your car safe.

Safety Gear

Safety Glasses: Wear these to keep your eyes safe from sparks or bits.

Work Gloves: These keep your hands safe from sharp wires and help you hold tools better.

Car Safety Steps

Disconnect the Battery: Always take off the battery before doing any electrical work. This stops shocks and short circuits.

Keep the Car Still: Make sure the car is on a flat surface and won't move while you work.

By getting the right tools and being safe, you can do a good job. Remember, being ready can stop problems later.

Finding the Right Connectors

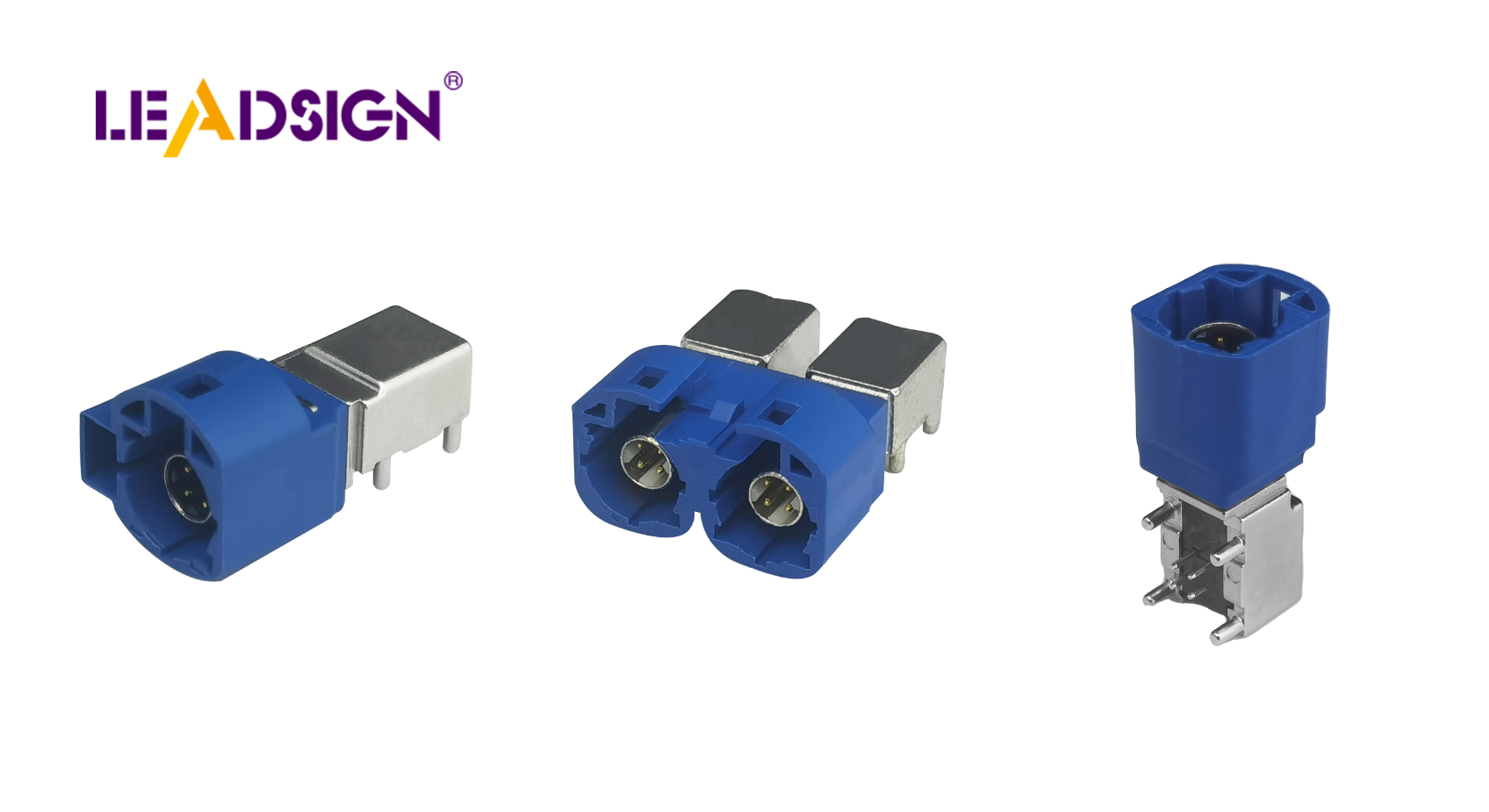

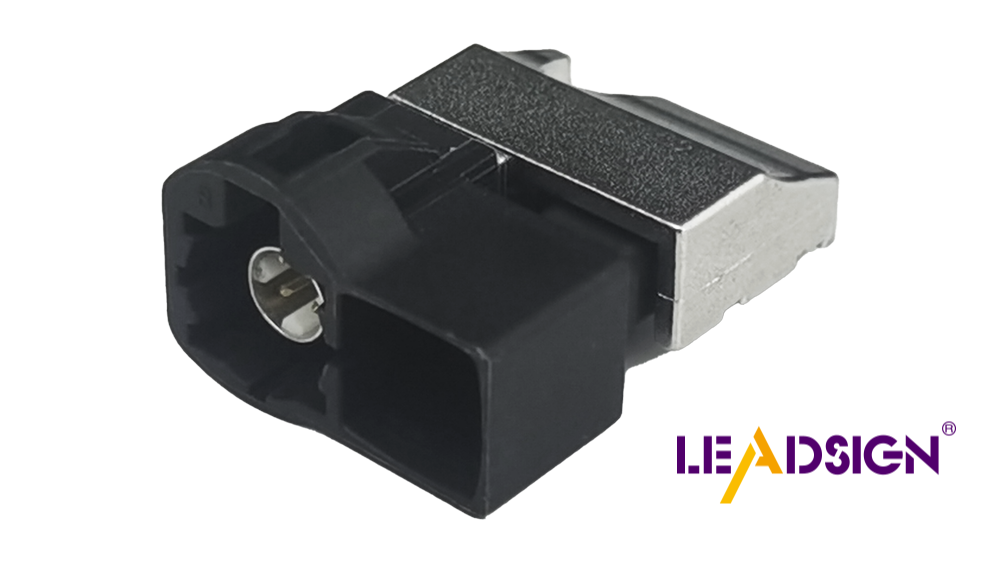

Picking the right connectors is key for your car's electrical parts to work well. These tiny parts help send power and signals all over the car, so it's important to know their types and details.

Knowing Connector Types

When choosing connectors, you should know the different kinds. This helps you make smart choices that boost your car's performance.

OEM vs. Aftermarket Connectors

OEM Connectors: These are made just for your car's brand and model. They fit perfectly and work well. Using OEM connectors stops problems and keeps your car's electrical system strong.

Aftermarket Connectors: Made by other companies, these come in more styles and prices. They can be cheaper, but make sure they are good quality and fit your car.

Connector Material and Strength

The stuff connectors are made of affects how long they last. Good materials don't rust or wear out, keeping connections strong. Look for ones made of brass or copper. These materials conduct electricity well and resist damage.

Matching Connectors to Car Needs

To pick the right connectors, match them to what your car needs as per the maker's guide.

Checking Car Guide

Your car's guide is helpful for finding the right connectors. It gives details about what each part needs. Always check the guide to make sure they fit and avoid problems.

Asking Car Experts

If you're not sure which connectors to get, ask car experts. People like Essen Deinki stress picking top-quality connectors for better car reliability. They can help you choose the right ones for your car.

"Electrical connectors are key in cars, making sure power and signals move smoothly." - Essen Deinki

By knowing connector types and matching them to your car's needs, you ensure a strong and efficient electrical system. This care not only boosts performance but also makes your car safer and last longer.

Step-by-Step Installation Process

Disconnecting the Battery

Before working on vehicle connectors, disconnect the car battery. This keeps you safe and stops electrical problems.

Safety Precautions

Turn Off the Vehicle: Make sure the car is off. This stops accidental electricity flow.

Wear Safety Gear: Put on safety glasses and gloves. They protect you from sparks and sharp parts.

Proper Disconnection Techniques

Locate the Battery: Find the battery in your car. It's usually under the hood.

Disconnect the Car Battery Terminals: Use a wrench to loosen the negative terminal nut first. Remove it carefully. Then, do the same for the positive terminal. This order stops short circuits.

Remove a Car Battery: If needed, lift the battery straight up. Be careful; it can be heavy.

Removing Old Connectors

After disconnecting the battery, remove old connectors. This step is important for a clean installation of new ones.

Identifying Old Connectors

Inspect the Wiring: Look at the wires to find old connectors. They might be worn or rusty.

Check the Vehicle Manual: Use your car manual to find and confirm the connectors you need to change.

Safe Removal Techniques

Use Proper Tools: Use pliers or a screwdriver to gently remove old connectors. Don't pull wires directly.

Clean Battery Terminals: If connectors are on the battery, clean terminals with a brush to remove rust.

Installing New Connectors

With old connectors gone, install new ones. Be careful to make a secure connection.

Preparing the Wiring

Strip the Wires: Use wire strippers to remove a bit of insulation. This shows the metal for better connection.

Check for Damage: Look for any wire damage. Replace bad wires for a strong connection.

Attaching the Connectors

Select the Right Terminals: Pick the right terminals for your connectors. OEM ones fit easily.

Crimp the Terminals: Use a crimping tool to attach terminals tightly to wires. Make sure they fit well to avoid loose connections.

Securing and Testing the Connection

Attach the Terminals to the Battery: If needed, connect terminals back to the battery. Start with the positive, then the negative.

Test the Connection: Use a multimeter to check electricity flow. Make sure everything works before adding a new battery or putting parts back.

By following these steps, you can replace vehicle connectors and make a strong connection. This helps your car work better and last longer.

Fixing Common Problems

When putting in automotive plugs and connectors, you might face some usual problems. Knowing these issues and how to solve them keeps your car's electrical system working well.

Connection Issues

Loose or Bad Connections

Loose or bad connections can stop electricity in your car. Check the terminals often for looseness or damage. A good connector lets signals pass easily. If a connection is loose, tighten it with the right tools. Look for rust too. Rust can weaken connections and cause failures. Clean terminals with a wire brush to remove rust and make a strong connection.

Wrong Connectors

Using wrong connectors can cause big problems in your car's electrical system. Always pick connectors that fit your car's needs. Eigen, a trusted maker, says using OEM connectors is important. These connectors fit well with your car's system. If you think connectors don't fit, check your car manual or ask an expert. This stops electrical problems and improves car performance.

Electrical Problems

Finding Issues

Electrical problems can come from different places. Start by checking battery terminals for rust. Rust can block electricity, causing problems. If you changed a car battery, make sure terminals are clean and tight. Use a multimeter to test electricity flow. This tool finds any problems in the current. If readings are off, look deeper into the issue.

Fixes and Solutions

Once you find the problem, fix it right. For rusty terminals, clean them well and add a protective layer to stop more rust. If connectors are the problem, switch them with good OEM connectors. This ensures a strong connection and stops future issues. When changing a car battery, check connections are tight. Regular checks and care of the electrical system stop problems and help your car last longer.

By fixing these common problems, you keep a strong and good electrical system in your car. Regular checks and care make sure your car works well and safely.

Putting in car plugs and connectors needs some important steps. First, get the tools you need and wear safety gear. Take off the battery to stop electric shocks. Gently take out old connectors and put in new ones. Make sure they fit well. Check and care for connectors often to keep your car working well. By doing these steps, you make your car safer and better. Enjoy the feeling of doing a good job yourself, knowing you helped your car last longer and work better.

FAQ

Why are automotive connectors not as strong as motorcycle ones?

Car connectors are weaker than motorcycle ones. Motorcycle connectors handle tough conditions better, making them stronger.

What do electrical connectors do in cars?

Electrical connectors are important in cars. They help power and signals move smoothly. Picking the right ones and installing them well makes your car work better. Essen Deinki offers top connectors for your car needs.

What standards do OEM car wire connectors meet?

OEM car wire connectors are made to high standards. They help parts talk and send power well. Knowing about OEM connectors helps you choose wisely for your car.

What materials are OEM car connectors made from?

OEM connectors are made for specific cars. They use strong materials that resist heat and wetness, making them last long.

How do I pick the right car connectors?

To pick the right connectors, check your car's needs. Look in the car manual or ask experts. Choose connectors made of brass or copper for better use.

Why disconnect the battery before adding connectors?

Disconnecting the battery is safe. It stops shocks and short circuits. Always turn off the car and wear safety gear first.

How do I make sure new connectors fit well?

Use the right tools like a crimping tool. Strip wires right, pick correct terminals, and crimp tight. Test with a multimeter to check electricity flow.

What if connections are loose or bad?

Tighten loose connections with tools. Clean rust with a brush. Check connectors often to keep them working well.

Can I use non-OEM connectors?

Non-OEM connectors have more styles and prices. Make sure they fit well. OEM ones fit perfectly and work best. Check your car manual or ask experts if unsure.

How do I stop electrical problems in my car?

Stop problems by checking your car's electrical parts often. Clean battery ends, tighten connections, and change bad wires or connectors. Using good OEM connectors helps too.

See Also

Exploring Ford Fakra Connectors: A Detailed Overview

In-Depth Insights on HSD Connectors for Professionals

Understanding HSD Connectors: Key Concepts for Automotive