Installing RF Connectors: A Comprehensive Guide

RF connectors play a crucial role in communication systems, facilitating efficient signal transmission at radio frequencies. Coaxial RF connectors are particularly effective in the megahertz range. Before beginning installation, it's essential to identify the specific connector required for your application, such as an RJ45 female connector for certain uses. Possessing the appropriate tools and materials is vital. Accurate measurement and preparation of cables are key to preventing signal loss. Understanding these aspects ensures a successful and secure installation.

Understanding RF Connectors

Types of RF Connectors

Coaxial Connectors

Coaxial connectors are important in many gadgets. They work well with radio waves, especially in megahertz. These connectors keep coaxial cables safe, reducing power loss and signal bounce. TVs, Wi-Fi tools, and radios use them for best results.

Twinaxial Connectors

Twinaxial connectors have a special design for fast digital signals. They are used where signal quality matters a lot. You find them in military, space, and communication gear. The twinaxial style blocks noise well, perfect for places with lots of interference.

Triaxial Connectors

Triaxial connectors have more shielding than coaxials. This extra layer stops interference better. They're often used in sensitive measuring tools and broadcasting jobs. Their design keeps signals clear, which is key for accurate data sending.

Applications of RF Connectors

Telecommunications

RF connectors are key in telecoms. They link parts in wireless networks like 4G and 5G systems. Board-to-board and panel-mount types connect big radio units and antennas.

Broadcasting

Broadcasting needs RF connectors to send signals well. Coaxials are common in TV and radio broadcasts to avoid signal loss. Good RF connections keep broadcasts clear.

Military and Aerospace

Military and space need strong connections. RF connectors give stable links for communication and radar gear. They're tough enough for the harsh conditions these fields face.

Tools and Materials Needed

Important Tools

Crimping Tools

Crimping tools help join cables to connectors. They press the connector onto the cable tightly. This makes a strong link. Good crimping stops signal problems. Pick crimping tools that fit your connector size.

Soldering Equipment

Soldering tools attach connectors to cables. Use a solder iron to melt metal and connect parts. Soldering gives a solid electric link. Make sure the solder iron can change heat levels. This keeps delicate parts safe from harm.

Cable Strippers

Cable strippers take off cable covers. They show the wires inside for connecting. Accurate stripping is key for good connections. Get strippers with changeable blades for different cables.

Suggested Materials

Connector Kits

Connector kits have many RF connectors types. Use them to find the right one you need. Kits also come with adapters and extras, making work easier.

Heat Shrink Tubing

Heat shrink tubing protects and insulates links. Cover open wires with it, then heat it up to fit snugly around them, keeping water out.

Electrical Tape

Electrical tape wraps around cables and connectors for safety. It adds more protection too. Choose strong tape that lasts long and works well.

Step-by-Step Installation Process

Getting the Cable Ready

Taking Off the Cable Cover

First, take off the cable cover to see the inside wire. Use a tool called a cable stripper for this job. Put the cable in the tool and turn it around. This takes off the outside cover without hurting the wire. Make sure you strip just enough to fit your connector.

Checking the Cable

Look at the cable after taking off its cover. See if there are any cuts or scratches on it. A bad wire can make signals weak. Keep the shield safe so signals stay strong. Good checking stops problems when connecting.

Putting on the Connector

Using Crimping Tools

Crimping tools help attach connectors to cables tightly. Put the bare wire into your connector first. Line up with crimping tool's jaws next. Squeeze hard to lock them together well. A good crimp means strong contact and less signal loss.

Using Soldering Tools

Soldering makes sure connectors stick well to wires. Heat up your solder iron right before starting work. Add melted solder between wire and connector parts carefully. Let it cool down before moving anything again.

Testing Your Work

Checking Connection Pathway

Test if everything connects right by using a multimeter device now! Check how easy electricity flows through connections made earlier today! Low numbers mean all is fine; high ones show something needs fixing soon!

Checking Signal Strength

See how good signals move from start point till end spot too! Hook up both ends of cable then measure strength received later on! Strong readings prove success while weak ones need more attention given here!

Best Practices and Tips

Making Sure Connections are Good

Stopping Signal Loss

Signal loss can mess up systems. Make sure the RF connector fits tightly with the cable. Use the right tools to attach connectors well. Loose connections make signals weak. Check if the connector's middle part lines up right when installing. This stops misalignment, which causes signal loss.

Keeping Connectors Strong

Strong connectors work better. Be gentle with RF connectors to avoid breaking them. Don't bend or twist cables too much. Doing that can make connectors weak. Check for damage often and replace bad ones fast to keep things working well.

Staying Safe

Using Tools Carefully

Safety matters when using tools for installation. Always use tools made for RF connectors. Crimping and soldering need careful handling. Wear gloves and safety glasses to stay safe from harm. Keep your tools in good shape for safe use.

Handling Electrical Parts Safely

Be careful with electrical parts. Turn off power before starting work to stop shocks. Follow rules for using RF connectors safely. Grounding helps prevent static electricity problems. Keep your workspace clean to avoid accidents.

Troubleshooting Common Issues

Poor Signal Quality

Identifying Causes

Weak signals come from different problems. Loose connections make signals weak. If connectors aren't lined up right, signals get worse. Outside interference, like electromagnetic fields, can mess up signals too. Using bad cables or connectors makes things worse.

Solutions and Fixes

To fix signal issues, make sure connections are tight. Align the connector with the cable correctly. Use good quality cables and connectors for your needs. Shield cables to block outside interference. Check your setup often to find problems early.

Connector Damage

Prevention Tips

Stop damage by handling connectors carefully. Don't bend or twist cables too much; it weakens them. Use tools made for RF connectors to avoid stress on parts. Keep connectors in a dry place to stop rusting. Look at them regularly to catch wear before it gets bad.

Repair Options

Fixing damaged connectors takes steps. First, check how bad the damage is to see if you can fix it. For small problems like loose parts, re-crimping or re-soldering might work. Replace badly damaged ones for best results. If unsure about fixing, ask a pro for help.

FAQs

Common Questions

How to pick the right connector?

To pick an RF connector, know what your project needs. Think about the frequency and power it uses. Check if it will face tough weather like heat or wetness. Zinc cobalt connectors last 48 hours in bad weather, good for rough places. See how strong the connector needs to be. Some things, like radar and drones, use black ones because they hide well. Make sure the connector fits your cable type. Coaxial, twinaxial, and triaxial are used for different jobs.

What if the connector is loose?

A loose connector makes signals weak and can break things. First, check if it's lined up right; wrong alignment makes it loose. Use a crimping tool to hold it tight on the cable. If it's screwed on, make sure it's tight enough. Look for damage on both parts and change them if needed fast. In tough spots, use heat shrink tubing or tape for extra help. Regular checks stop future problems with loose connectors.

Installing RF connectors has important steps. Each step helps make a strong connection. Preparing and attaching connectors right stops signal loss. Following good methods keeps the system working well. High costs and risks show why careful work is needed. More digital tools and 5G need good RF setups. Getting help from experts is smart. They guide you and keep things safe during setup. Asking for help makes your communication systems better.

See Also

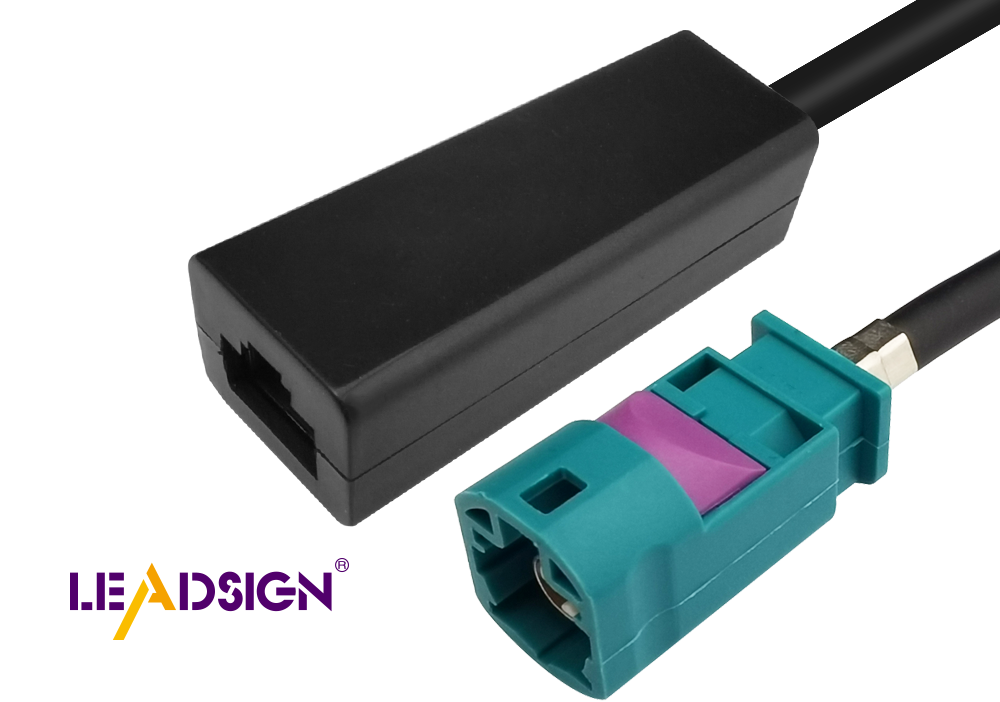

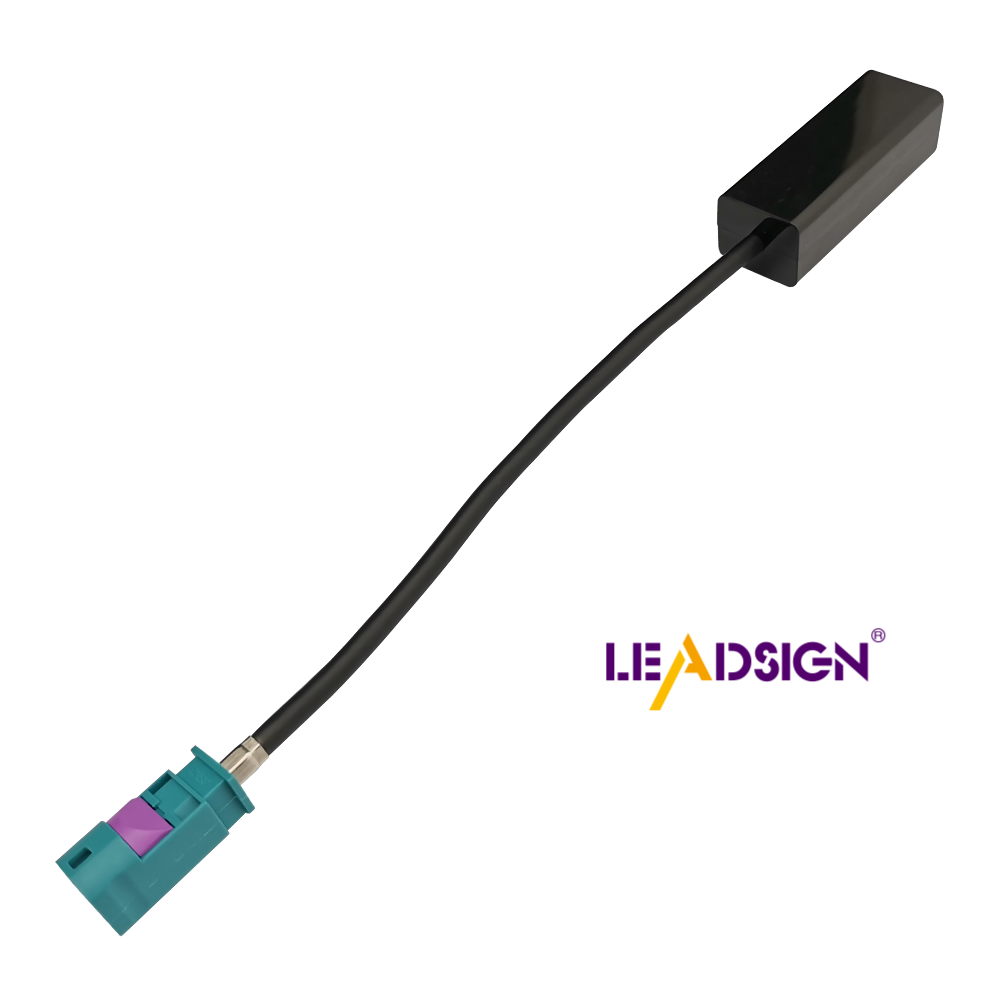

Discovering the Potential of Compact Fakra Connectors: An In-Depth Manual

Comprehending FAKRA Connectors: An Extensive Overview

An In-Depth Look at Fakra Connectors: Benefits, Uses, and Setup Suggestions