Comprehensive Guide to Installing Car Wiring Wire Safely

Putting in car wiring wire safely is very important. It keeps your car working well and keeps you safe while driving. Bad wiring can cause problems like blinking lights or broken signals. These issues can be dangerous on the road. By following clear steps, you can avoid mistakes. This also helps meet car wiring rules. Using the right tools and materials is important. Safety steps like unplugging the battery and wearing safety gear help too. These steps make sure the wiring is done safely and works well.

Key Takeaways

Always prepare by gathering the right tools and materials, such as wire strippers, multimeters, and automotive wiring kits, to ensure a smooth installation process.

Prioritize safety by disconnecting the car battery before starting any wiring work to prevent shocks and short circuits.

Understand the different types of wires (power, ground, signal) and their appropriate uses to ensure a reliable electrical system.

Make strong connections using crimping or soldering techniques, and always test connections with a multimeter to confirm they are secure and functioning.

Plan your wiring layout carefully to avoid sharp edges and hot areas, and use zip ties and covers to keep wires organized and protected.

Follow local wiring regulations and manufacturer instructions to ensure compliance and safety in your installation.

Regularly check and maintain your wiring connections to prevent issues and ensure long-lasting performance.

Preparation: Tools, Materials, and Safety Precautions

Before starting with your car wiring wire, get ready first. Having the right tools, materials, and safety steps makes the job easier. This section explains what you need.

Tools You Need for Wiring

To install wires well, you need good tools. These tools help you work faster and get better results.

Wire Strippers, Crimpers, and Cutters

Use wire strippers to remove wire covers without harm. Crimpers with front jaws work well in tight spots. Wire cutters trim wires to the right size. For thick wires, use cutters for 8-gauge or more.Multimeter for Testing Connections

A multimeter checks voltage, resistance, and connections. It ensures your wires are working properly. Every car DIYer should have one.Heat Shrink Tubing and Electrical Tape

Heat shrink tubing covers and protects wire connections. Use a heat gun to make it fit tightly. Electrical tape is good for quick fixes but not long-term.Screwdrivers, Wrenches, and Zip Ties

Screwdrivers and wrenches secure parts during wiring. Zip ties keep wires neat and stop them from tangling.

Materials You Need for Wiring

Having the right materials is as important as tools. These items make your wiring safe and long-lasting.

Automotive Wiring Kit Components

A wiring kit has labeled wires, connectors, and instructions. It makes wiring easier and reduces mistakes.Fuses, Connectors, and Terminals

Fuses stop electrical overloads. Connectors and terminals make strong, safe connections. Always pick parts that match your wiring needs.Wire Loom or Conduit for Protection

Wire loom or conduit protects wires from heat and damage. It also keeps wires tidy for better reliability.

Safety Steps to Follow

Safety is the most important part of wiring. These steps keep you safe and avoid accidents.

Disconnecting the Car Battery Before Starting

Always unplug the battery before wiring. This stops shocks and short circuits.Wearing Protective Gloves and Eyewear

Gloves protect your hands from cuts and burns. Eyewear keeps your eyes safe from sparks and debris.Ensuring a Clean and Well-Lit Workspace

A clean area helps you find small parts easily. Good lighting makes wiring easier and safer.

By preparing well, you can install your car wiring wire successfully. With the right tools, materials, and safety steps, your wiring will work perfectly.

Understanding Wiring Basics: Wire Types, Connections, and Diagrams

Knowing car wiring basics is key for a good installation. This section explains wire types, connections, and reading wiring diagrams.

Types of Car Wiring Wire and Their Uses

Picking the right car wiring wire keeps your system safe. Each wire type has a job in the system.

Power wires, ground wires, and signal wires

Power wires bring electricity from the battery to car parts. They carry strong currents and need to be tough.

Ground wires link parts back to the car frame or battery. They make sure the system works properly.

Signal wires send data or small signals between devices. These wires are thin and more fragile than power wires.

Picking the right wire thickness

Wire thickness, or gauge, shows how much current it can carry. Thick wires (low gauge) are best for power. Thin wires (high gauge) work for signals. Always match the wire size to the part's needs to avoid problems.

Common Wire Connections and Terminals

Good connections make your wiring reliable. Learn how to make strong and lasting connections.

Crimping vs. soldering wires

Crimping presses a connector onto a wire with a tool. It’s fast, easy, and often used in cars.

Soldering melts metal to join wires or attach them. It’s strong but takes more time and skill.

Use crimping for most jobs. Use soldering for wires in tough conditions.

Using connectors and terminals correctly

Connectors and terminals make joining wires easier. Insulated connectors stop short circuits. Make sure terminals fit tightly in connectors. Label wires to avoid mistakes during setup.

Reading Wiring Diagrams

Wiring diagrams are like maps for your wire setup. They show how everything connects.

Understanding symbols and colors

Diagrams use symbols for parts like switches and lights. Learn these symbols to read the diagram. Colors show wire jobs. For example, red is often for power, and black is for ground.

Planning the wiring path in your car

Before starting, plan where wires will go. Map the route from the battery to the parts. Avoid sharp edges or moving parts that could harm wires. Use wire covers to protect and organize them.

By learning these basics, you can install wires confidently. Knowing wire types, connections, and diagrams makes the process smooth and safe.

Step-by-Step Guide to Installing Car Wiring Wire

Putting in car wiring needs good planning and careful work. Follow these steps to make sure it’s done safely and correctly.

Planning the Wiring Layout

Finding the power source and ground spots

First, find your car’s power source, usually the battery. The positive terminal sends power, and the negative terminal is for grounding. Grounding completes the circuit and keeps it working. Look for clean metal spots on the car frame for grounding. Make sure these spots are free of rust or dirt for a strong connection.

Choosing the best wire paths

Plan where the wires will go before starting. Check your car’s layout and avoid sharp edges, moving parts, or hot areas. Use existing clips or channels to hold wires in place. This keeps them safe and neat. Mark the planned paths with tape or chalk to guide you during the work.

Routing and Securing the Wires

Running wires through the car

Carefully run wires through the engine area and into the car’s interior. Use a grommet when passing wires through the firewall to stop damage. Keep wires away from hot parts like the engine or exhaust. Inside, place wires under the carpet or along the sides of panels. This keeps them safe and out of sight.

Using zip ties and covers to organize

Use zip ties to hold wires in place and stop tangling. Space the ties evenly for a clean look. Cover wires with a loom or conduit for extra protection. This shields them from heat, water, and damage. A tidy setup looks better and lasts longer.

Connecting the Wires

Making strong connections

Join wires securely by crimping or soldering them. Use a crimping tool to attach connectors tightly. For stronger connections, solder the wires and cover them with heat shrink tubing. Don’t leave wires exposed to avoid shorts or rust. Test each connection with a multimeter to make sure it works.

Adding fuses and connectors

Follow the wiring diagram to add fuses and connectors. Fuses stop overloads, so pick the right size for each circuit. Connectors make joining wires easier and help with future repairs. Label connectors to avoid mistakes later.

By following these steps, you can install car wiring safely and properly. Good planning, neat routing, and strong connections are the keys to success.

Testing and Completing the Installation

After finishing the connections, you need to test your work. This ensures the wire harness and connections are safe and ready.

Checking Continuity and Voltage with a Multimeter

A multimeter is a key tool for testing wires. It checks if electricity flows smoothly and if voltage levels are correct. Follow these steps:

Set the Multimeter to Continuity

Turn the multimeter to the continuity setting. This checks if electricity flows without breaks.Test Each Wire or Connection

Place the probes on both ends of a wire. A beep or low resistance means the connection is good. No sound or high resistance means there’s an issue. Check for loose wires or damage.Switch to Voltage Mode

Change the multimeter to voltage mode. This checks if each part gets the right power.Measure Voltage at Important Points

Test voltage at the battery, fuse box, and other spots. Compare readings to the wiring diagram. If numbers don’t match, there may be a problem with the wire harness assembly or a bad connection.

Using a multimeter ensures your wiring is safe before moving on.

Reconnecting the Battery and Testing Everything

Once the wiring is checked, reconnect the battery and test the system. Follow these steps:

Reconnect Battery Terminals

Attach the positive terminal first, then the negative. Tighten them well to avoid loose connections.Turn On the System

Start the ignition to power the system. Watch for any strange issues like flickering lights or devices not working.Test Each Part Separately

Check each connected part. For example, if you install the hardwire kit for a dashcam, make sure it powers on. Test lights, sensors, or other devices to confirm they work.Check for Heat or Sparks

During testing, touch wires lightly to check for heat. Look for sparks or odd smells, which could mean a short circuit or bad installation.Secure the Wire Harness

After testing, check the wire harness routing. Use zip ties to secure wires and cover them with loom or conduit. This keeps them safe and neat.

Thorough testing ensures your car wiring wire setup is safe and works well. By following this guide, you can finish confidently and enjoy a reliable system in your car.

Safety and Compliance: Tips for a Safe Installation

Keeping safety in mind during car wiring is very important. It protects your car and helps your electrical system last longer. Follow these tips to make your setup safe and reliable.

Staying Safe with Electrical Work

Electrical safety should always come first. Taking simple steps can prevent accidents and keep your wiring working well.

Fixing loose or open wires

Loose or open wires can cause short circuits or fires. Check your wire harness carefully after finishing the work. Cover open spots with heat shrink tubing or electrical tape. Use zip ties or clips to hold wires in place. This stops wires from moving and getting damaged by rubbing or shaking.

Checking all connections twice

Checking connections twice makes sure everything works right. Use a multimeter to test each connection for proper voltage and flow. This tool helps find weak or bad connections. Fix any problems right away to avoid bigger issues later. Testing ensures power flows safely through the system.

Following Wiring Rules

Following wiring rules makes sure your setup is safe and legal. These rules also help your wiring fit your car properly.

Using the maker’s instructions

Always follow the maker’s instructions when installing a wire harness. These instructions tell you which wires, connectors, and fuses to use. Using the right materials and methods keeps your wiring reliable and error-free.

Following local wiring rules

Local wiring rules keep cars safe and standardized. Learn the rules in your area before starting the job. Make sure your wiring follows these rules to avoid trouble. Following them also keeps your car safe and ready for the road.

By focusing on safety and rules, you can build a strong wiring system. Securing wires, testing connections, and following standards will make your setup safe and dependable.

To install car wiring wire safely, prepare and stay focused. Gather the right tools and learn basic wiring steps. Follow a clear guide to make your setup work well. Always prioritize safety by unplugging the battery first. Secure the wire harness to protect your car and yourself. Use standards like ISO 6722 and SAE J1128 for safe, quality wiring. Work carefully and check every connection twice. A good installation ensures smooth power flow and lasting performance.

FAQ

What makes a wire harness different from a cable assembly?

A wire harness holds and protects many wires in one bundle. It makes setup easier and keeps wires safe. A cable assembly connects devices with cables that have plugs on both ends. Each is used for different jobs, so pick the one that fits your project.

Why is it important to unplug the car battery first?

Unplugging the car battery stops shocks and short circuits. It keeps you safe while working on wires. Always take off the negative terminal first to avoid sparks.

How do you pick the right wire thickness?

The wire thickness depends on how much electricity it carries. Thick wires (low numbers) are for more power. Thin wires (high numbers) are for smaller loads. Check the device guide or a chart to choose the right size.

What tools do you need to install a dash cam?

To install a dash cam, you need wire strippers, crimpers, and a multimeter. These tools help you prepare wires, connect them, and test the setup. Heat shrink tubing and tape are also good for protecting connections.

How can you keep your wires neat?

Use zip ties and covers to organize wires. Run wires along existing paths or under panels to stop tangling. Label wires to make future fixes easier.

What do fuses do in a wiring system?

Fuses stop wires from getting too much electricity. They break the circuit if the current gets too high. Always use the right fuse size to keep the system safe.

How do you check your wiring after finishing?

Use a multimeter to test for smooth electricity flow. Check each connection to make sure it works. Reconnect the battery and turn on the system to confirm everything is fine.

Should you reuse old connectors and terminals?

It’s not a good idea to reuse old connectors or terminals. Worn parts can cause weak links or failures. Always use new, good-quality parts for a strong setup.

What safety steps should you follow when wiring?

Wear gloves and goggles to stay safe. Work in a clean, bright space to avoid mistakes. Check all connections twice to make sure they are secure.

How do you follow local wiring rules?

Learn the wiring rules in your area before starting. Follow the maker’s instructions and use approved materials. This keeps your wiring safe and legal.

See Also

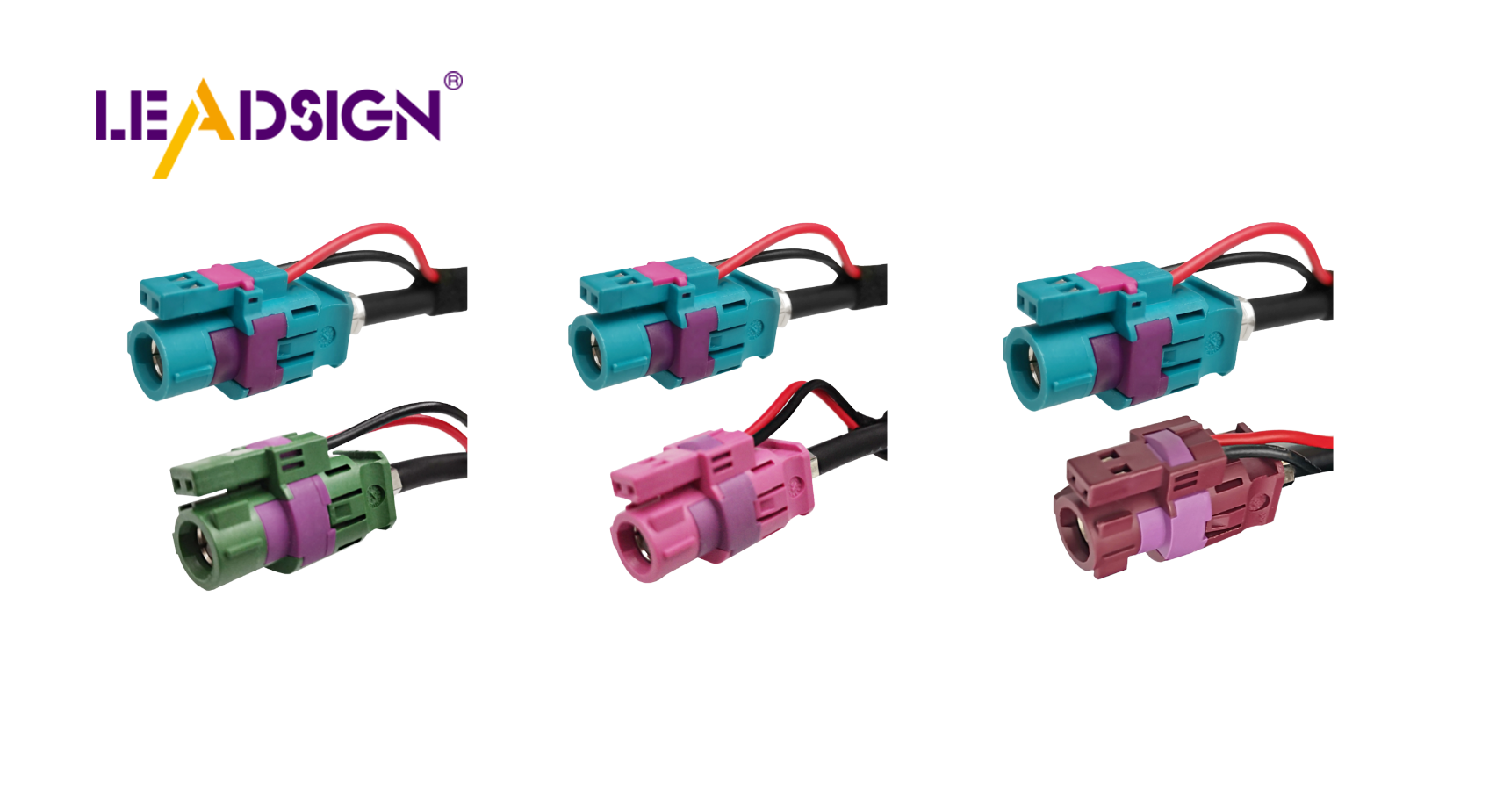

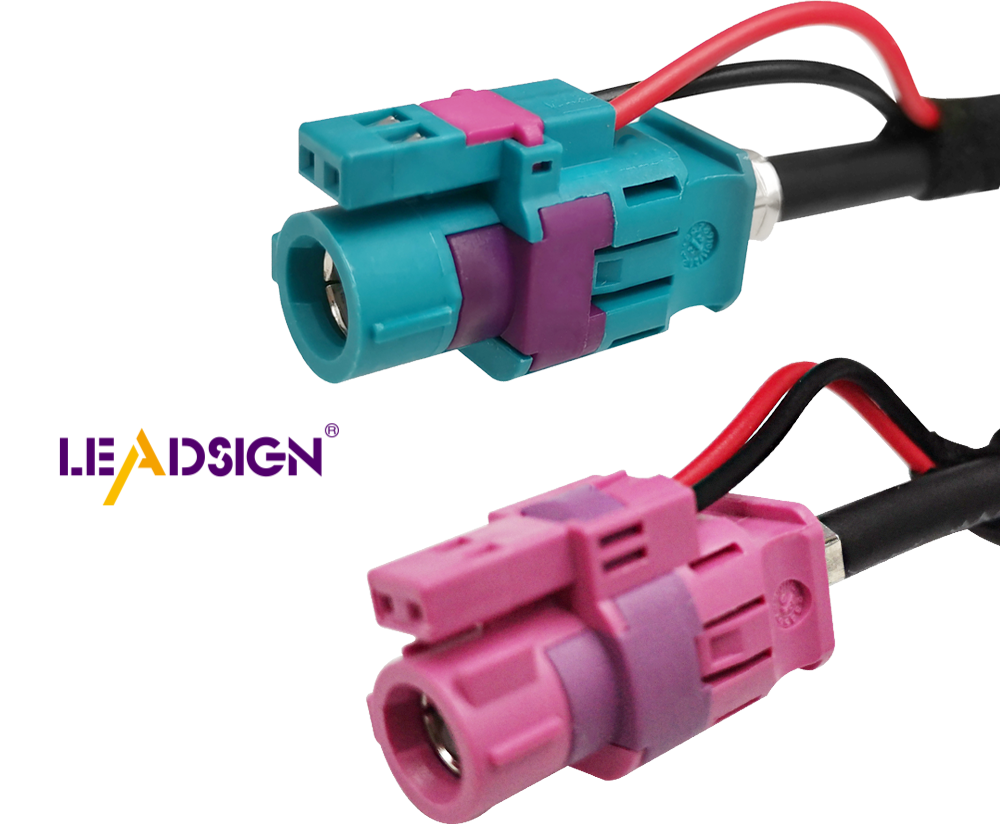

Everything You Need to Know About HSD Connectors

Understanding Ford Fakra Connectors: A Complete Guide

Fakra HSD LVDS 4 Pin Connector: Your Wiring Handbook