Installing Automotive Wire Connectors: A Step-by-Step Guide

In car electronics, good wire connections are important, especially when using various automotive wire connectors types. They help your car's systems work well and safely by providing strong and safe links, lowering electrical problems. These connectors make the job easier and better. You need some tools to start, like wire strippers and crimpers. With good prep, you can do great work on car projects.

Tools and Materials Needed

To start with car wire connectors, you need some tools. Let's see what you should have.

Important Tools

Wire Strippers

Wire strippers are very important. They take off the wire cover without harming the metal. Pick ones that fit your wire size for a clean strip.

Crimping Tool

A crimping tool is key for attaching connectors to wires. It presses them tightly together. Get one with settings for different sizes to make strong connections.

Heat Gun

A heat gun shrinks tubing over connections, protecting from water and more. It's like a snug coat for wires. Be careful not to overheat them.

Needed Materials

Wire Connectors

Wire connectors come in types like butt, ring, and spade terminals. Choose based on your needs for a stable connection.

Heat Shrink Tubing

Heat shrink tubing insulates connections by shrinking tight when heated. It stops short circuits and guards against damage.

Electrical Tape

Electrical tape wraps and insulates wires, adding protection and bundling them together. Keep some handy for quick fixes.

With these tools and materials, you're ready for wiring projects. The right gear makes it easier and looks professional. Happy wiring!

Preparing the Wires

Getting your wires ready is a crucial step. Let's dive into how you can do it right.

Cutting the Wires

Measuring the Required Length

First, measure the wire length you need. Use a ruler or tape measure. Make sure you have enough wire to reach your connection points without being too tight or too loose. This helps avoid stress on the wires.

Using Wire Cutters

Once you've measured, grab your wire cutters. Hold the wire firmly and cut it cleanly. A neat cut ensures a better connection later. Keep your fingers clear of the blades for safety.

Stripping the Wire Insulation

Selecting the Correct Gauge

Next, choose the right gauge for your wire. Check the wire's thickness and match it with your wire stripper's settings. This ensures you remove just the insulation without damaging the wire itself.

Proper Stripping Technique

Now, it's time to strip the insulation. Place the wire in the stripper at the correct gauge setting. Squeeze gently and pull the stripper towards the end of the wire. This should leave you with a clean, exposed wire ready for connecting.

By following these steps, you'll have your wires perfectly prepped for the next stage. Happy wiring!

Installing the Wire Connectors

Your wires are ready. Now, put on the connectors. This step helps your car systems work well.

Picking the Right Connector

Types of Connectors

There are different wire connectors. Butt connectors join two wires straight. Ring terminals hook wires to a bolt or screw. Spade terminals slide onto a bolt or screw. Each has its own job, so choose what you need.

Connector Fit

Make sure the connector fits your wire size and use. Check the package details. Using the wrong one can cause bad connections and problems.

Putting on the Connector

Inserting the Wire

Push the bare wire into the connector. The wire should touch metal inside for a strong link. If it doesn’t fit well, cut or strip more of it.

Crimping the Connector

Use a crimper tool to tighten the connector. Put it in the tool and squeeze hard. A tight crimp keeps it secure. Test by pulling gently; it shouldn’t move.

Securing Everything

Adding Heat Shrink Tubing

Slide heat shrink over where they connect. Use a heat gun to make it tight and safe from water and harm.

Wrapping with Electrical Tape

Wrap tape around for extra safety and neatness. It also keeps wires together, reducing mess and risks.

Follow these steps for safe connections that last long! Different connectors help in many projects, making them easy to do right!

Finishing the Setup

You're nearly finished! Let's check everything is right and working.

Checking the Connection

Making Sure It's Tight

First, see if the connector is tight. Pull it gently. It shouldn't wiggle or come off. A tight fit means your connection is strong.

No Bare Wires Showing

Look at the wires closely. Ensure no metal parts are visible. Bare wires can cause problems like short circuits. If you see any, cover them with tape or fix the connector.

Testing Your Work

Using a Multimeter Tool

Now, test your setup. Get a multimeter tool. Set it to check resistance or continuity. This helps you know if electricity flows well.

Checking Electricity Flow

Touch the multimeter ends to both sides of your connection. If it beeps or shows low resistance, your work is good. If not, look over your work again. Make sure it's all tight and secure.

By doing these steps, you make sure wire connectors are set up right in your car. This keeps things running smoothly and safely. Well done on finishing the job!

You've learned how to put on car wire connectors. This guide showed you each step, from getting tools to checking connections. Safe connections are important for your car's safety and work well. Different wire connectors help you find the right one for each job. Keep practicing to get better at using them. The more you use these connectors, the more sure you'll be. So, take your tools and try out different wire connectors. Enjoy wiring!

See Also

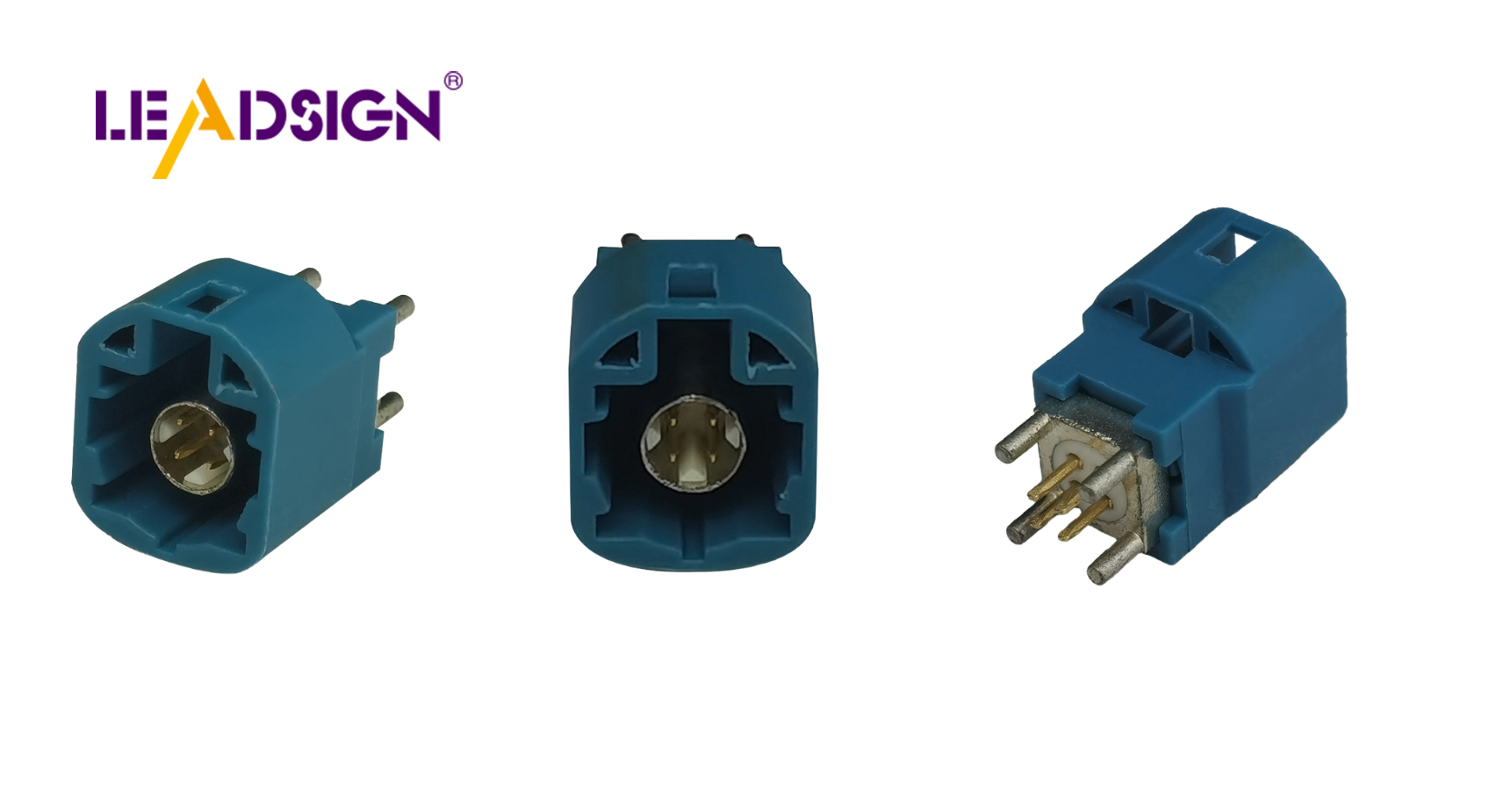

Exploring Ford Fakra Connectors: A Comprehensive Overview

Mastering HSD Connectors: An Extensive Overview

Essential HSD Connectors in Automotive: A Fundamental Look