Installing Car Wire Connector Types: A How-To Guide

Choosing the right automotive electrical connectors types is crucial for ensuring that your car's connections are safe and function properly. Selecting the wrong type can lead to issues, accounting for 45% of all failures. This highlights the importance of making informed choices. Follow the steps to install these connectors correctly, which minimizes errors and enhances the longevity of the connections. A proper installation prevents problems before they arise and helps maintain the safety and efficiency of your car's electrical system.

Getting Ready

Collecting Needed Tools

To start installing car wire connectors, you must have the right tools. The correct tools make the installation easy and quick.

Important tools for connector installation

Wire Strippers: Use these to take off the wire cover without harm.

Crimping Tool: This tool is key for attaching connectors to wires. A good crimp makes a strong connection.

Multimeter: Check the connection with this after you finish, to make sure it works.

Extra tools for better work

Heat Gun: This helps shrink tubes over connections, keeping them safe from water.

Connector Crimp and Depin Tool: Was $50.00, now $39.99. It helps crimp and remove pins from connectors.

Connector and Pigtail Repair Terminal Release Kit: Was $133.33, now $99.99. It fixes and releases terminals well.

Staying Safe

Safety is very important when working with electrical parts. Following rules keeps you and your car safe.

Safety steps to follow

Always unplug the car battery before starting any work to avoid shocks.

Wear safety goggles to keep your eyes safe from sparks or bits.

Use insulated tools to lower shock risk.

Making a safe workspace

Make sure your area is bright and tidy; less mess means fewer accidents.

Keep flammable things away from where you work; this stops fires.

Have a fire extinguisher close by in case of emergencies.

By getting needed tools and staying safe, you're ready for a successful car wire connector installation.

Checking Connectors

Look at Current Connectors

Before changing connectors, check their condition. This saves time and parts.

Spotting Damage or Wear

Look closely at connectors. See cracks, rust, or color changes? These show damage. If a connector is loose or wires are worn out, replace it. Bad connectors cause weak power flow and problems.

Deciding on Replacement

If you see damage, think about replacing it. Replace worn ones to stop future problems. Different cars need special connectors for best work. Picking the right one makes them last longer and work well.

Knowing Connector Details

Knowing your connector details is key. It helps pick the right one that fits your car.

Use Car Manual for Help

Check your car's manual first. It tells you what size and type of connectors you need. The manual helps match the right connector to your car's needs.

Find Connector Type and Size

Find out which type and size you need. Connectors do different jobs like engine control or lights. Each has its own strength and use. Knowing this helps choose well for safe connections.

By checking conditions and knowing details, you're ready to install correctly. This makes sure your connectors fit your car's needs safely.

Buying

Picking the Right Connector

Choosing the right connector is important. It keeps your car safe and working well. Match the connector to your car's needs. Different cars need different connectors. Always check your car's manual first. This helps you pick the right size and type for a good fit.

Matching connectors to Car Needs

Check Your Manual: Your car's manual tells you about needed automotive electrical connectors types. It gives details on size, type, and sometimes brand.

Know Its Job: Connectors do different jobs like engine control or lights. Knowing this helps pick the right one.

Think About Weather: Some connectors handle heat or wet places better. Choose ones that fit where you drive.

Quality and Brand Matter

Good quality and brands last longer and work better for automotive electrical connectors types. Pick brands known for being strong.

Eaton Automotive Connectors: They make good parts used by many big car makers.

TE Connectivity Automotive Connectors: Their products are tough for hard conditions.

Phoenix Contact Automotive Connectors: They offer smart solutions with great parts.

C&K Automotive Connectors: They provide strong, reliable connectors with weather protection.

Using real connectors from trusted brands keeps your car safe. Cheaper ones might break because they aren't tested well.

Where to Shop

Finding places to buy automotive electrical connectors types saves time and money. You can shop online or in stores.

Best Places to Buy

Local Auto Parts Stores: These have many connectors and help quickly if needed.

Online Shops: Sites like Amazon or eBay have lots of choices with reviews to guide you.

Maker Websites: Buying from Eaton or TE Connectivity means getting real products directly.

Tips for Good Deals

Compare Prices: Look at different places to get a good price on needed parts.

Find Discounts: Online shops often have sales or coupons during events.

Buy More Together: If needing many, buying in bulk lowers cost per piece.

Look for Free Shipping: Some shops ship free over certain amounts, saving money.

By choosing the right parts from good sources, your car stays safe and works well.

Installation

Easy Steps to Install

Putting in a new car wire connector is simple. Follow these steps for success.

Taking Out the Old Connector

Unplug the Battery: First, unplug the car battery to stay safe from shocks.

Find the Connector: Look for the old connector you need to change. Remember wire colors and spots.

Cut Wires Carefully: Use cutters to cut wires from the old connector. Leave enough wire for new use.

Strip Wire Ends: Take off about a quarter-inch of cover with strippers. This shows copper for connecting.

Remove Old Connector: If clips or screws hold it, take them out to free the connector.

Putting On the New Connector Right

Get New Connector Ready: Make sure it fits your car's needs. Check your manual if unsure.

Add Seals First: For waterproof ones, put seals on wires before pins go on.

Crimp Pins Firmly: Use crimp tool to fix pins on stripped ends tightly.

Place Pins in Housing: Put crimped pins into new connector case until they click in place.

Fix New Connector In Place: Attach it where needed in your car using clips or screws if needed.

Checking It Works

After putting in the new one, check that it works right.

Making Sure It's Safe and Steady

Plug Battery Back In: After placing new connector, plug battery back in.

Test with Multimeter: Use this tool to check connection works and no shorts exist.

Look Over Connection: Check visually that all wires are lined up and tight.

Fixing Usual Problems

Check Loose Parts: If shaky, recheck crimping and pin placement.

Confirm Wire Spots: Make sure wires match notes from removal time.

Spot Any Damage: Look at wires and connector for damage that could cause issues later.

Expert Tip: Experts say good crimping keeps connectors working well long-term, stopping future electrical problems and keeping cars running smoothly.

By following these easy steps, you can put in car wire connectors safely and keep your car's electric parts working well.

To put in car wire connectors right, do these steps: get the tools you need, stay safe, check old connectors, buy the right new ones, and install them carefully. Keeping your car's wires working is important. Look at connectors often for damage and change them if needed. Use good quality parts to make sure they work well. If you have trouble or don't know what to do, ask a pro for help. Car electric connectors are key for keeping your car safe and running well. Take care of them to stop surprise problems.

See Also

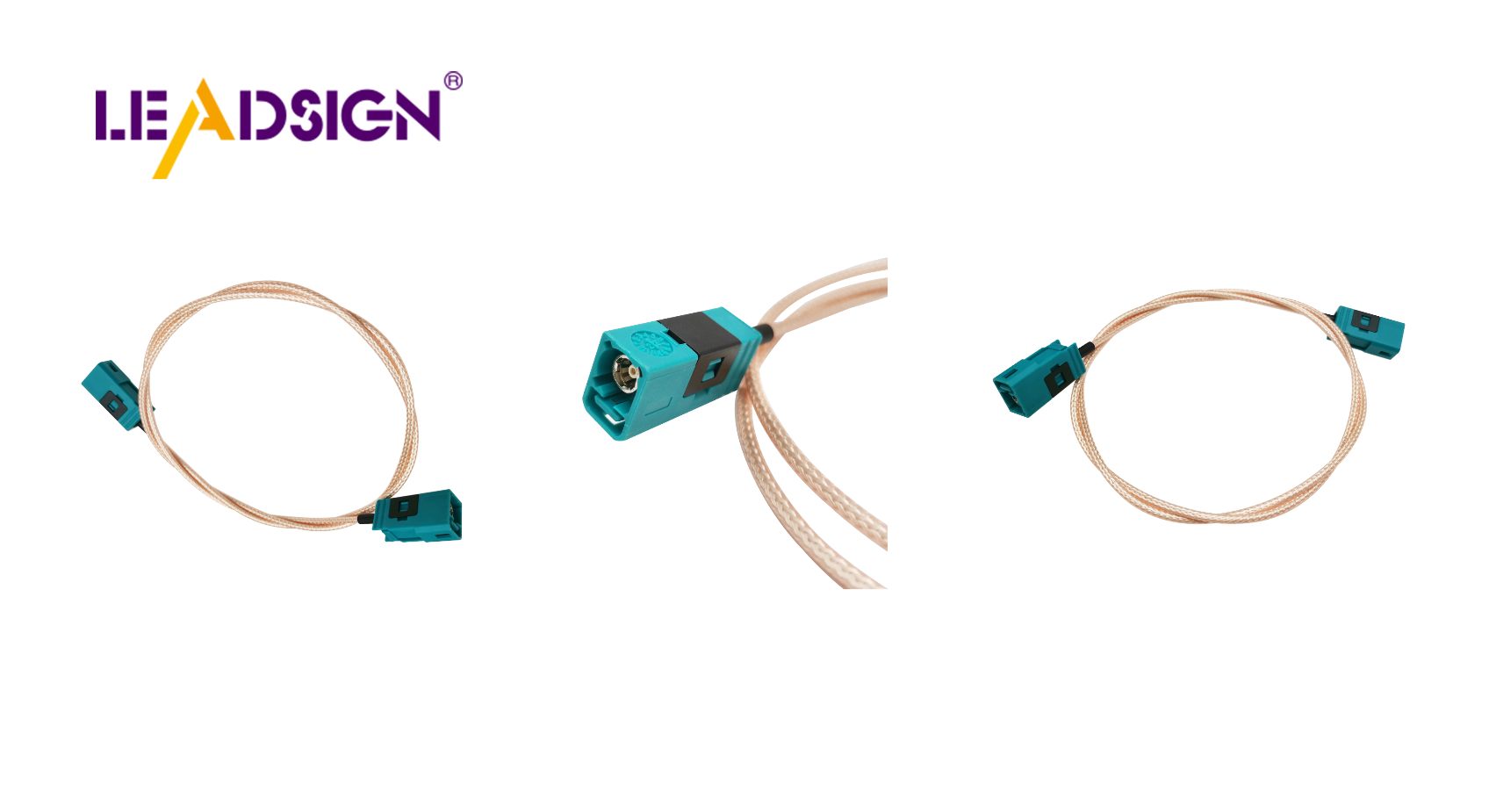

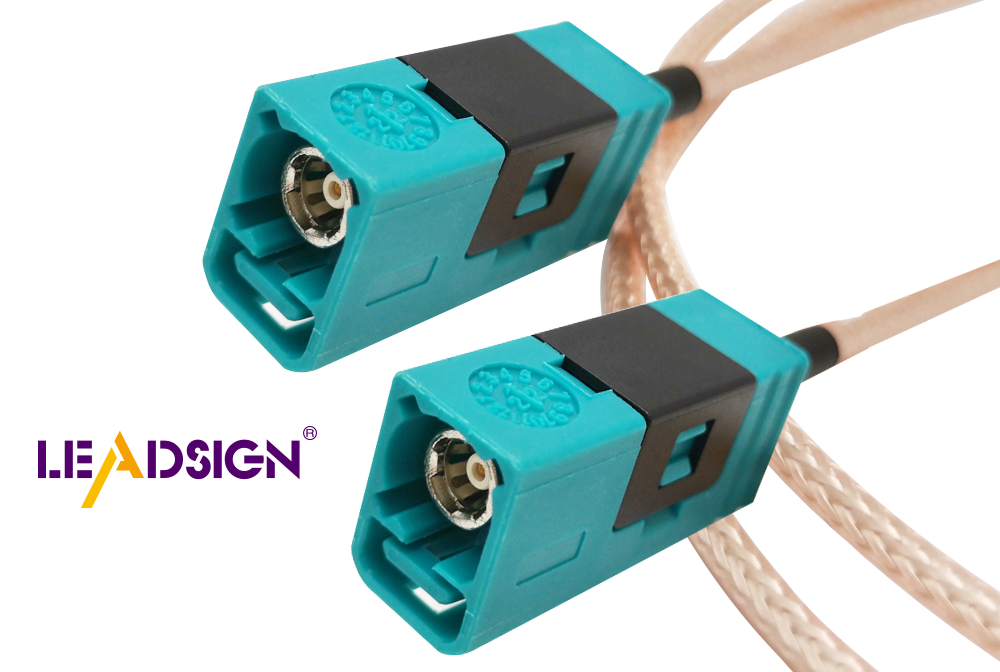

Understanding Ford Fakra Connectors: A Complete Overview

Fakra Connectors Explained: Benefits, Uses, and Setup Advice

Everything You Need to Know About HSD Connectors