Installing Auto Wire Connector Types: A Comprehensive How-To

Automotive electrical connectors types are crucial components in car systems. They play a vital role in ensuring the smooth flow of electricity, which is essential for the proper functioning and safety of the vehicle. There are various types of automotive electrical connectors designed for specific purposes. Selecting the appropriate connector is important to prevent electrical issues, as faulty connections account for approximately 45% of car problems. It is recommended to use genuine parts and adhere to safety guidelines to maintain the optimal performance of your car's electrical wiring.

Understanding Car Electrical Connectors

Car electrical connectors are important parts of your car. They help electricity flow smoothly so everything works right. Knowing about these connectors helps you fix your car's electrical system.

Types of Car Electrical Connectors

Car connectors come in different shapes and sizes for specific jobs. Here are some common ones:

Butt Connectors

Butt connectors join two wires together. Use them to make a wire longer or fix a broken one. They hold wires tightly and are simple to use. Strip the wire ends, put them in the connector, and squeeze it tight.

Ring Terminals

Ring terminals attach a wire to a bolt or screw securely. You see them often on batteries or grounding spots. To use, strip the wire, put it in the terminal, and squeeze it tight. Then screw it onto where you need it.

Spade Terminals

Spade terminals let you connect wires quickly. They are good when you need to unplug wires often. Strip the wire, put it in the terminal, and squeeze it tight. The spade shape makes attaching easy.

Bullet Connectors

Bullet connectors snap together easily for quick connections. They have male and female parts that fit together snugly. Use them where wires need frequent connecting and disconnecting. Strip the wire, insert into the connector, crimp it, then snap together.

Picking the Right Connector

Choosing the right car electrical connector is key for safe connections. Think about these things:

Material and Size Choices

Connectors can be plastic or metal. Plastic is light and strong for most uses; metal is better for tough jobs because it's stronger. Pick based on what you need.

Wire Size Match

Make sure your connector fits your wire size (gauge). Wrong size can cause bad connections or failures later on! Always check if they match before using.

By knowing about different car electrical connectors types and picking right ones, you keep your car working well and safely.

Tools and Materials Needed

When using car wire connectors, having the right tools is important. These tools make work easier and help keep connections safe.

Important Tools for Connecting

To connect car wires well, you need some main tools:

Wire Strippers

Wire strippers are needed to get wires ready. They take off the plastic cover without hurting the wire. This tool makes sure enough wire shows for a good connection.

Crimping Tools

Crimping tools attach connectors to wires. They press the connector onto the wire tightly. A good crimper makes a strong hold, which is key for car wires.

Heat Guns

Heat guns shrink special tubes over connections. This adds extra cover and keeps water out. A heat gun helps seal tight, making connections last longer.

Suggested Materials for Safe Connections

Besides tools, some materials help keep connections strong:

Heat Shrink Tubing

Heat shrink tubing covers and shrinks when heated. It insulates and guards against things like water and dirt. Using it makes car wire connections more reliable.

Electrical Tape

Electrical tape wraps around wires to protect them. It stops short circuits and adds safety. Though not as tough as tubing, it's easy to use.

By having these tools and materials, you can connect car wires safely. This helps your car's electric system work better and stay safe.

Step-by-Step Installation Guide

Putting in automotive electrical connectors types needs careful work. Follow these steps for a strong and safe connection.

Getting the Wires Ready

Taking Off Wire Cover

First, remove the plastic cover from wire ends. Use a wire stripper to show about a quarter-inch of bare wire. This is important for a good connection. Be careful not to hurt the wire strands.

Twisting Wire Pieces

After stripping, twist the bare wires together. Twisting keeps them neat and helps fit into the connector easily. It also makes the connection stronger.

Connecting the Wire

Putting Wire in Connector

Push twisted wire into the connector fully. Make sure it touches metal inside for best electricity flow.

Crimping Connector Tight

Use crimping tools to lock connector onto wire tightly. Press hard for a strong hold. Crimping is great for car connectors because it's reliable.

Finishing and Securing Connection

Using Heat Shrink Tubing

Slide heat shrink tubing over connection area. Use heat gun to shrink it tight around connector, keeping water and dirt out.

Checking Connection Safety

Finally, check if everything is secure with no loose wires or gaps in cover.

Expert Advice: *Soldering can make very strong connections but needs skill.* Crimping is easier and works well for most car connectors.

By following these steps, you can put in automotive electrical connectors types safely and keep your car's system working well.

Installing car wire connectors right is very important. It keeps your car safe and working well. Good tools and materials help make strong connections. A user on a forum said using good wires and connectors matters a lot. Check websites like customconnectorkits.com for small wires. For big cables, try batterycablesusa.com. These choices make your car's electric system last longer and work better. Share what you know or ask questions in the comments. Your tips can help others with their car projects.

See Also

An Extensive Overview of HSD Connectors

Fundamentals of HSD Connectors in Automotive Sector

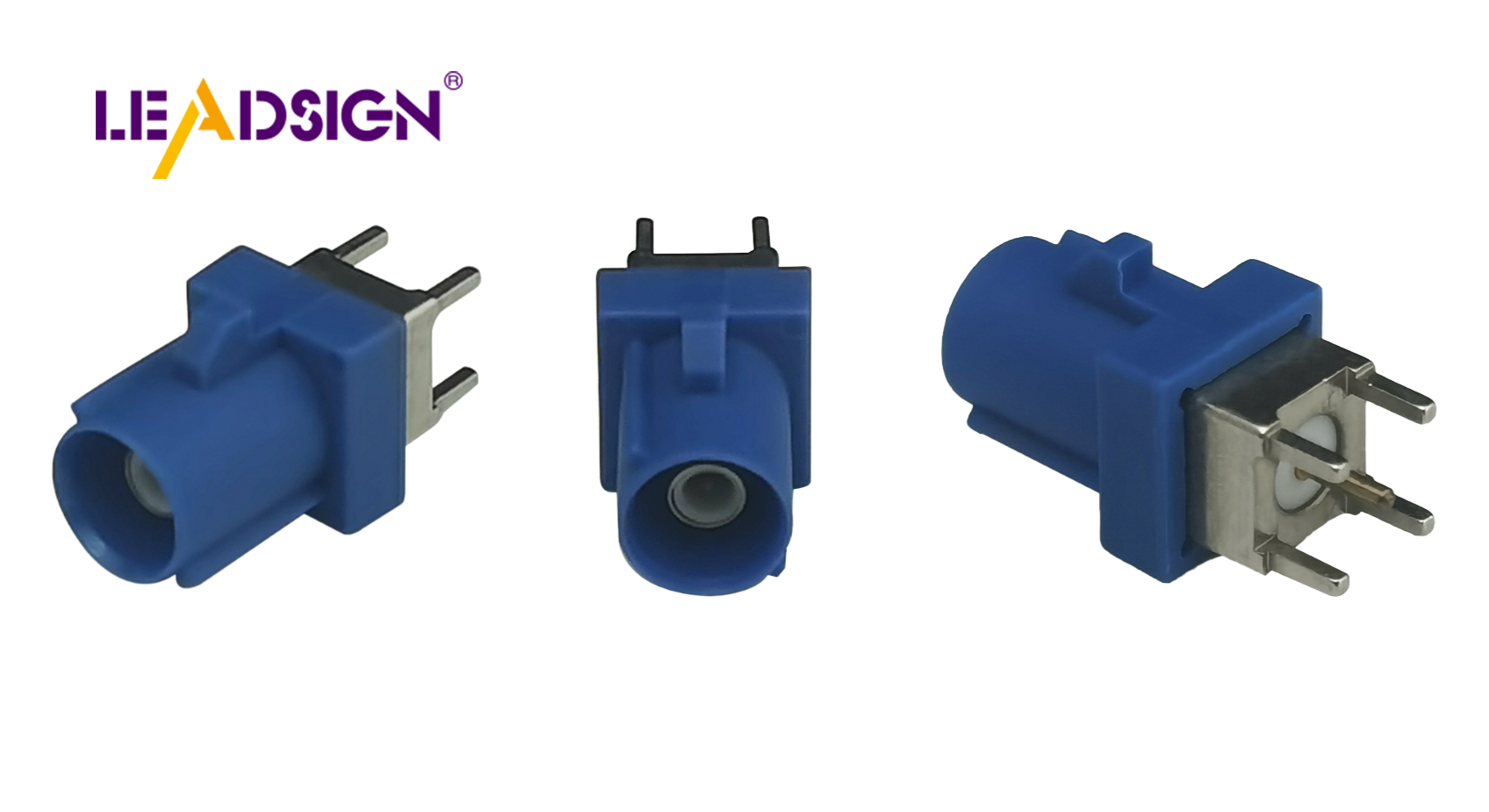

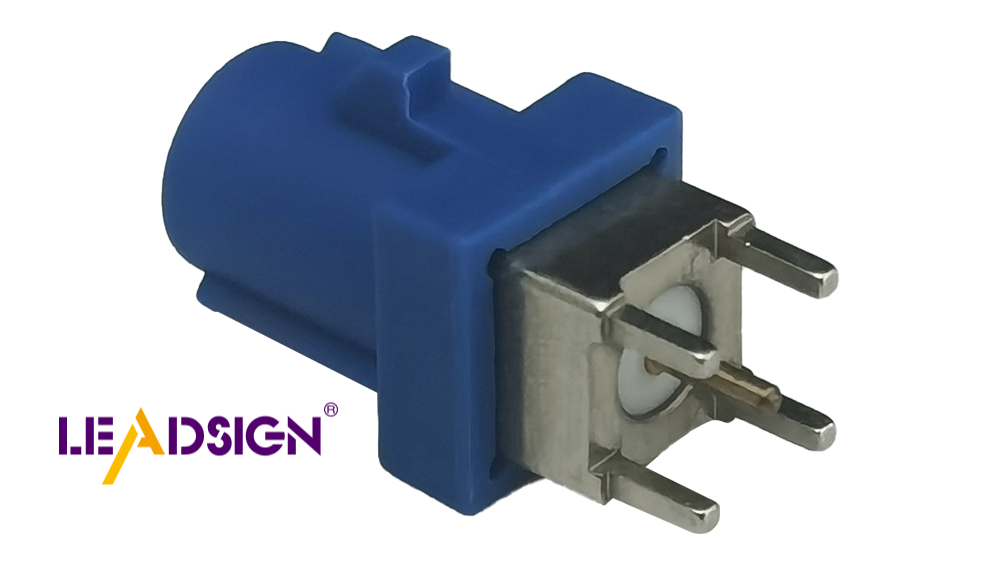

In-Depth Look at Fakra Female Connectors