How to Install and Secure Auto Wire Connector Types

Wire connectors automotive type are crucial for your vehicle's electrical system. They ensure secure connections between various components. However, improper installation can lead to issues such as electrical failures or safety hazards. Imagine driving and suddenly losing power due to a faulty connection. This highlights the importance of understanding wire connectors automotive type. By mastering their installation, you can prevent problems and maintain your car's optimal performance.

Understanding Wire Connectors Automotive Type

When fixing your car's electrical parts, know the different wire connectors automotive type. These connectors keep wires connected safely. Whether fixing, restoring, or building a custom car, knowing connector types and uses is key.

Common Wire Connectors Automotive Type

Butt Connectors

Butt connectors link two wires end-to-end. Use them to make a wire longer or connect without changing direction. They are easy and strong. Strip wire ends, put them in the connector, and crimp tight.

Ring Terminals

Ring terminals attach a wire to a stud or screw securely. You often see them in battery links or grounding jobs. The ring shape keeps it from coming loose easily. Slide over the stud and tighten with a nut.

Spade Terminals

Spade terminals, also called fork terminals, allow easy on-off connections. They're great when you need to remove connections often. The fork slides under a screw for quick securing or removal. Loosen the screw, slide in place, and tighten.

Choosing the Right Connector for Your Needs

Picking the right connector depends on many things. Think about what your project needs and if it fits your car's systems.

Factors to Consider

Wire Size: Match connector with wire size.

Environment: Think about moisture or heat exposure.

Current Load: Pick one that handles the electric load.

Compatibility with Vehicle Systems

Your car's system may have special needs. Always check if the connector fits your car’s systems well. This ensures top performance and avoids problems. Using correct wire connectors automotive type keeps your car’s electrical links strong.

Step-by-Step Installation Process

Installing car wire connectors needs careful work. Follow these steps for a safe and strong connection.

Getting Ready to Install

Collecting Tools

Before starting, get all your tools ready. You need:

Wire cutters

Crimp tool

Heat shrink tubes

Electric tape

Multimeter for checking

Having these tools helps make the job easier and faster.

Staying Safe

Safety is very important. Wear goggles to protect your eyes from bits flying around. Disconnect the car battery to stop shocks. Work in a place with fresh air so you don’t breathe bad fumes.

Putting on the Connectors

Cutting Wire Coating

First, cut off about a quarter-inch of plastic from each wire end. Use wire cutters carefully so you don’t hurt the wires inside. Good cutting is key for a strong link.

Adding the Connector

Put the bare wire into the right connector type. Make sure it fits tightly inside. This step is crucial for a solid connection.

Securing with Crimp Tool

Use a crimp tool to lock the connector onto the wire firmly. Press hard so it stays tight. A tight fit stops wires from slipping out and keeps connections stable.

Checking Your Work

Testing Fit Tightness

After crimping, pull gently on the wire to see if it’s attached well to the connector. If it slips out, crimp again until it holds tight. A snug fit means better performance.

Testing Electrical Flow

Use a multimeter to check if electricity flows through well. Set it to continuity mode and touch probes to both ends of the wire. A beep means it's good; no beep means check again.

By doing these steps, you can install car connectors confidently, keeping your vehicle's electric parts safe and working well.

Securing the Connectors

Securing connectors right helps your car's electric system last. Good connectors stop bad links, shorts, and fires. Here are ways to make sure your connectors stay safe.

Techniques for Securing Connectors

Using Heat Shrink Tubing

Heat shrink tubing fits tightly around connectors. After crimping, slide it over the link. Use a heat gun to shrink it down. This makes a waterproof cover, keeping water out and stopping rust. It also adds more insulation to stop shorts.

Applying Electrical Tape

Electrical tape is another way to secure connectors. Wrap tape tightly around the link. Cover all bare wire parts. This stops dust from getting in and adds more insulation for a strong connection.

Preventing Common Issues

Avoiding Loose connections

Loose connections can cause electric problems. To stop this, make sure connectors fit tight. After crimping, gently pull the wire. If it moves, crimp again until it's firm. A snug fit keeps your car's electric system working well.

Protecting Against Moisture and Corrosion

Water and rust can harm connectors over time. Use heat shrink tubing or tape to seal them off. This keeps water out and stops rusting. Check your connectors often for damage or wear signs. Replace any rusty ones to keep things running smoothly.

By using these methods, you can keep your connectors safe and working well longer. This boosts how well your car's electric system works too! Always use good quality connectors for safety.

You now know how to put on and secure car wire connectors well. This keeps your car's electrical system safe and working right. Check them often to avoid big, costly problems. Using good connectors makes your car's wires last longer and work better. Bad connections might cause shorts or fires. Try harder wiring projects next to learn more. This will make you better at fixing cars and improve how they run. Keep learning for safer driving!

See Also

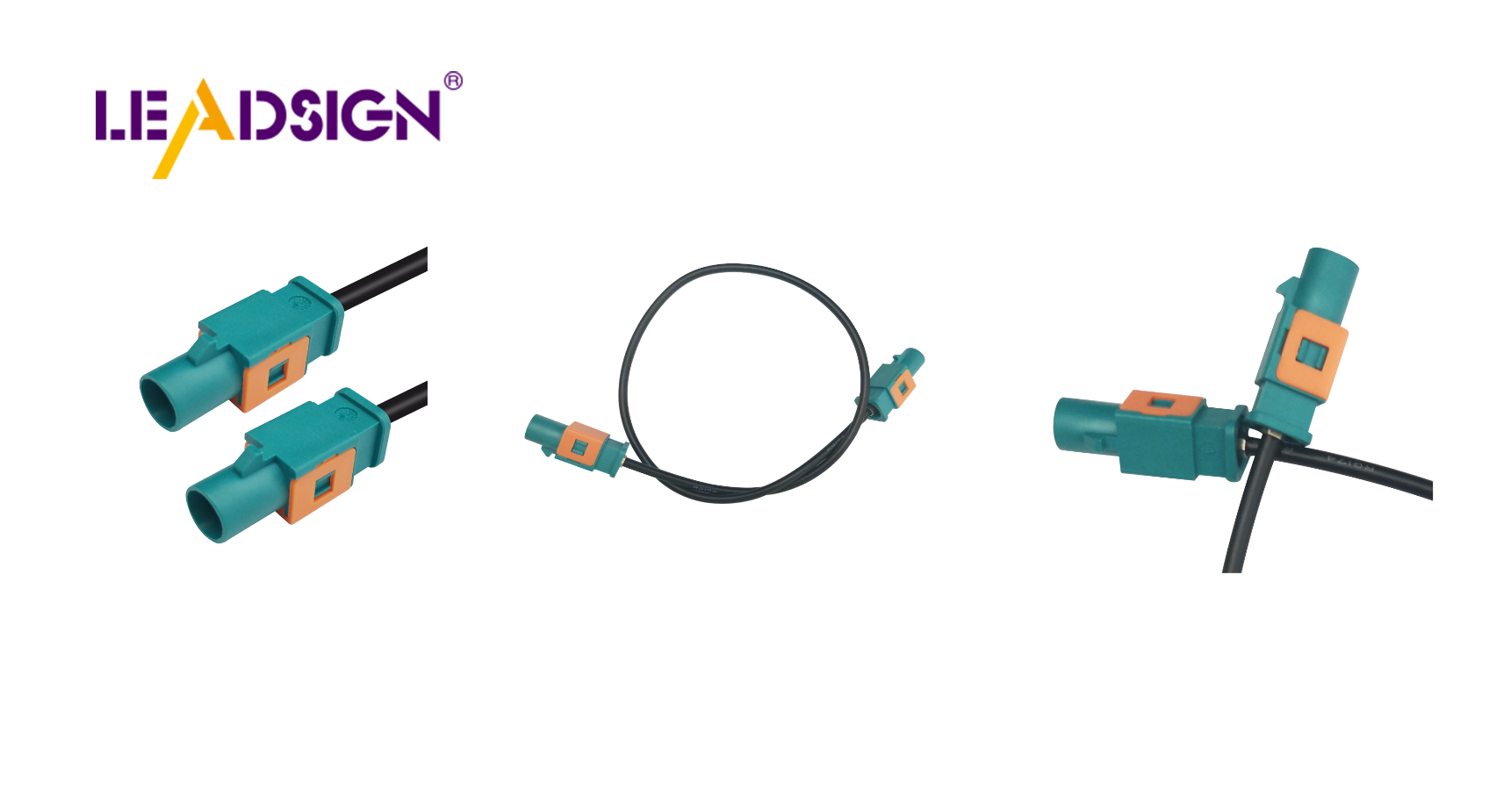

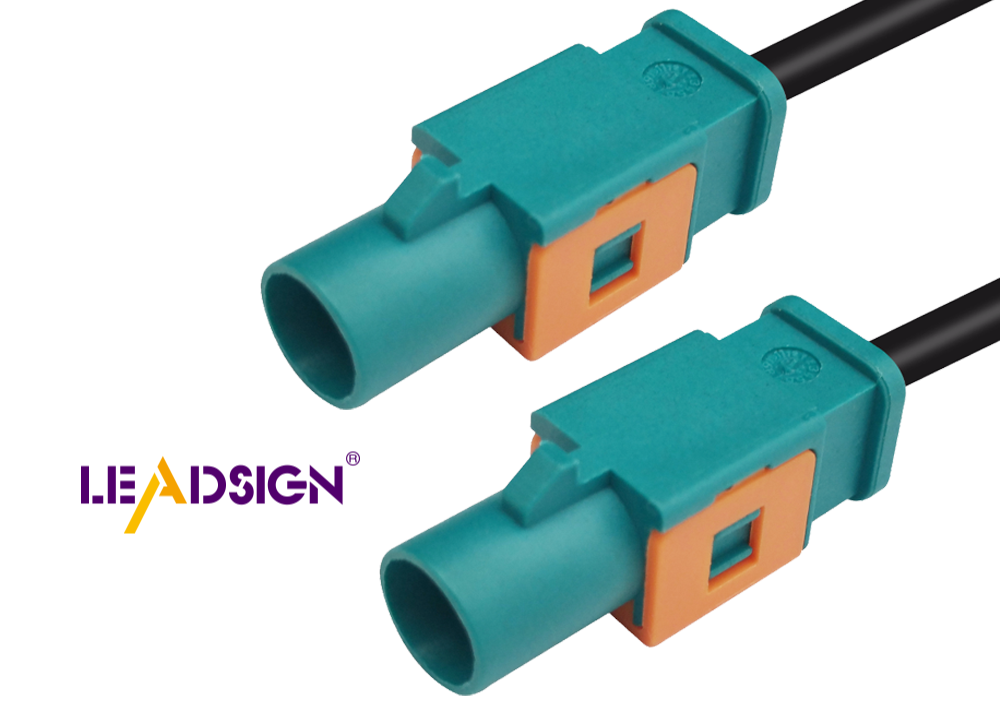

The Significance of FAKRA Connectors in Auto Industry

Essential Guide to HSD Connectors in Auto Sector

Maximizing Benefits: High-Speed FAKRA-Mini Connectors in Auto Sector