How to Install and Repair Automotive Electrical Connector Plugs in 2025

Car connector plugs are important for cars to work well. They help electrical parts communicate with each other. In 2025, installing and fixing them is more important. Cars now have more complex systems. Many cars use high-voltage systems, like 48 volts or higher. These systems power safety features and electric engines. Electric cars need special high-voltage plugs for safety and stability. These changes show why keeping plugs in good shape is key. Reliable plugs help cars perform their best.

Key Takeaways

Pick the correct car connector plug for your vehicle. Knowing the difference between terminal and blade plugs is important.

Stay safe when fixing car wires. Unplug the battery and follow safety rules to avoid harm.

Check and clean your car's plugs often. This easy task stops rust and keeps them working well.

Overview of Car Connector Plugs

Types of Car Connector Plugs

Modern cars use different types of electrical plug connectors. Each type has a unique job. Here are some common ones:

Terminal Connectors: These are simple and used for low-power tasks like lights and radios. They are cheap and easy to use but can rust and handle little power.

Blade Connectors: These are common in car wiring. They have flat metal pieces for strong connections. They come in many sizes and are dependable. But they might unplug by accident and can't handle much power.

Knowing these types helps you pick the right connector.

Common Applications in Vehicles

Car electrical plug connectors move power and signals between systems. As cars use more electronics, these connectors are even more important. They help systems like lights, radios, and sensors work properly. Good connectors keep your car's electrical parts running smoothly.

Features to Consider in 2025

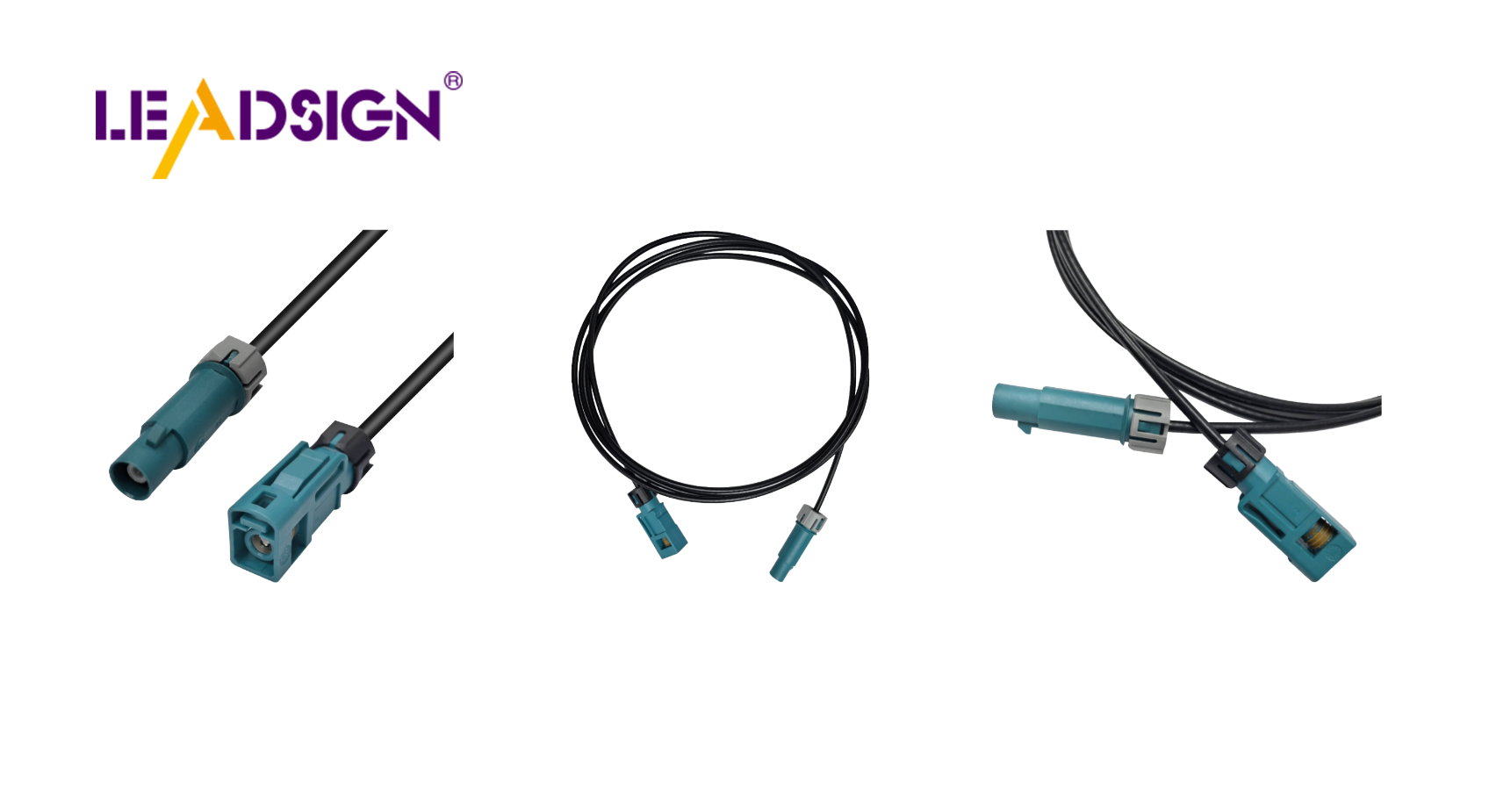

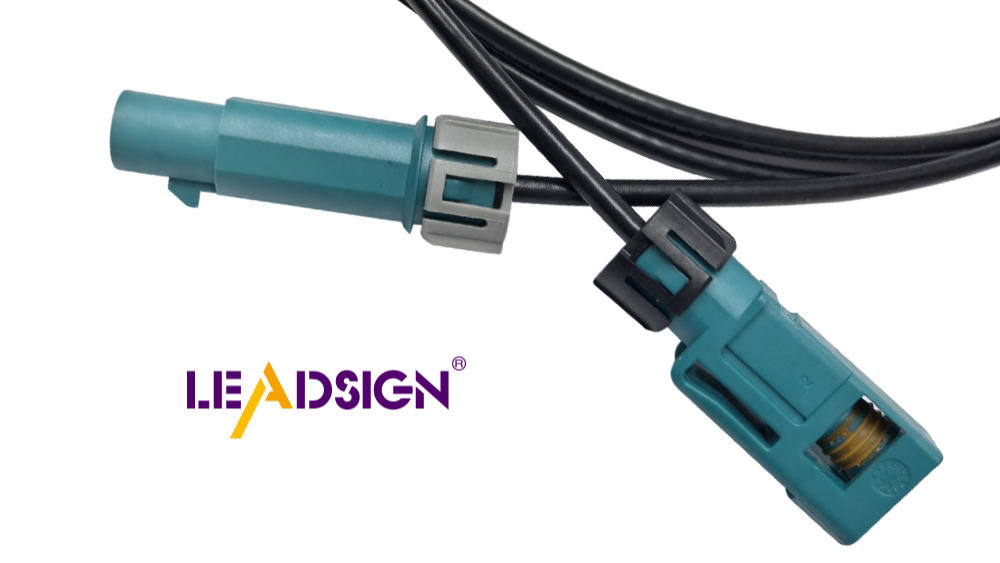

In 2025, choose car connector plugs that are reliable and efficient. Pick ones with locks to stop accidental unplugging. Waterproof connectors protect against weather damage. High-tech connectors, like FAKRA, work for GPS, Bluetooth, and keyless entry. They are fast, strong, and secure, making them great for modern cars. Choosing these features ensures your car stays updated and works well.

Tools and Safety for Installation and Repair

Essential Tools for Car Connector Plug Installation

Using the right tools makes the job easier. Gather these items before starting:

A crimper (Part# 11-001) to secure wires tightly.

A wire brush to clean rust from old connectors.

Heat shrink tubing to cover and protect soldered wires.

Good dielectric grease to keep connections safe from damage.

These tools help you work on car wiring accurately and safely.

Safety Measures to Follow

Safety is very important when fixing car wiring. Always disconnect the battery before starting work. This stops shocks or accidents. Be careful of airbags when working under the dashboard. Turn off the circuit and wait a few minutes first. Never work on wiring while the car is running. This prevents injuries and power surges. Following these rules keeps you and your car safe.

Preparing Your Workspace for Installation

A clean workspace makes installation easier. Pick a bright area with enough room to move. Keep tools nearby to avoid delays. Use a mat that doesn’t conduct electricity to stay safe. Make sure the area is dry to protect electrical parts. A good workspace helps you focus and finish the job smoothly.

Step-by-Step Guide to Installing Car Connector Plugs

Getting Wires and Pigtail Connectors Ready

Before installing a pigtail connector, prepare the wires first. Follow these steps:

Turn off the power. Use a tester to ensure no electricity flows.

Take out the switch or outlet from its box. Strip the wire ends to show the metal.

Cut the pigtail wire to the right length. Remove its insulation. Make sure it matches the original wire size.

Use wire nuts to join the pigtail and old wires. Twist them tightly for a strong hold.

Attach the pigtail to the device. Wrap it around the terminal screws and tighten them well.

Check all connections. Make sure they are tight and neat.

Good preparation helps the pigtail connector work safely and properly.

Connecting and Securing the Plug

After preparing the wires, connect and secure the car plug. Here’s how:

Use a crimping tool to attach male pins to the wires. This step makes the connection strong.

Slide a seal over the wires. This keeps moisture and dirt out.

Push the terminals into the connector housing. Make sure they click into place.

Check that the terminals are tight. Loose ones can cause problems later.

Securing the plug well stops it from coming loose and ensures it lasts.

Testing to Make Sure It Works

Once installed, test the car plug to confirm it works. Try these steps:

Test with a light to see if power reaches the plug.

Look for wiring mistakes or broken parts.

Check for shorts or voltage drops that might cause trouble.

Testing ensures the plug works right and avoids future issues.

Fixing and Checking Car Connector Plugs

Finding Common Problems with Car Connector Plugs

Car plug connectors can have problems that stop them from working. Look for these signs:

Loose plugs can make power stop or flicker. Tighten or change the plug to fix it.

Rusty plugs lose power over time. Clean them often and use grease to stop rust.

Burned plugs happen from too much heat or bad connections. Replace them quickly and find out why it happened.

Knowing these problems helps you fix them early.

Fixing Broken or Rusty Pigtail Connectors

Fixing car wires often means repairing broken or rusty pigtails. Do this:

Clean the wires well to remove rust or dirt. Use a wire brush for tough spots.

Put on a new pigtail by cutting the wire ends and using wire nuts. Make sure they are tight and follow the guide.

Add grease to keep the fixed part safe from rust later.

Always stay safe when fixing wires. A clean fix makes the pigtail work right.

When to Change a Plug Instead of Fixing It

Sometimes, changing a plug is better than fixing it. Replace it if:

The plug is too rusty to clean.

The plug is burned and can't be fixed. Solve the problem that caused it.

The plug case or lock is broken. A new one fits better.

Changing bad plugs keeps your car working well and avoids problems later.

Maintenance Tips for Long-Term Reliability

Regular Inspection and Cleaning of Connector Plugs

Check your car's electrical plugs often to keep them working. Look for dirt, rust, or loose parts during inspections. Cleaning them is easy and helpful. Use rubbing alcohol or contact cleaner to remove dirt. Plug and unplug the connector a few times to clean it. For tough grime, mix baking soda and water into a paste. Scrub with an old toothbrush, rinse with distilled water, and dry with air. Add terminal grease to stop rust from forming. Another way is soaking plugs in vinegar, rinsing with baking soda water, and adding silicone grease. These steps keep your plugs clean and working well.

Protecting Plugs from Environmental Damage

Moisture, dirt, and heat can harm your car's plugs. Protecting them helps them last longer. Use waterproof plugs to block water damage. Apply grease to keep out dirt and moisture. Cover open plugs with heat shrink tubing for extra safety. If your car faces tough weather, check the plugs more often. Keeping them clean and sealed stops rust and makes them last.

Upgrading to Modern Connectors for Better Performance

New connectors can make your car work better. FAKRA connectors are strong and reliable. They work well with GPS, Bluetooth, and keyless entry. These connectors lock tightly to avoid coming loose. If your old plugs are worn out, replace them with modern ones. New connectors fit better with today’s car systems. Upgrading improves your car’s wiring and gets it ready for the future.

Installing and fixing connector plugs helps your car run well. Checking them often stops problems and keeps them reliable. Look at parts like the battery and alternator regularly. This finds issues early and saves money and time. Learn about new tech like electric cars and smart plugs. Staying updated helps your car stay ready for the future.

FAQ

What is a pigtail connector, and why is it important?

A pigtail connector joins wires to devices safely. It keeps connections steady, stopping power issues or system failures in your car.

How do you protect connectors from environmental damage?

Use waterproof plugs to stop water damage. Add grease to block moisture. Cover open parts with heat shrink tubing. Check often to avoid rust or dirt.

When should you replace a connector instead of repairing it?

Change a connector if it’s too rusty, burned, or broken. A new one works better and stops the same problems from happening again.

See Also

Understanding HSD Connectors Within Automotive Applications

A Comprehensive Overview of Ford Fakra Connectors

Why FAKRA Connectors Matter in Automotive Systems

Benefits of HFM Connectors for Automotive Solutions

Exploring High-Speed FAKRA-Mini Connectors for Automotive Use