Master the Installation of PCB Board to Wire Connectors in Easy Steps

Installing pcb board to wire connectors is straightforward. By following the right steps, you can master this essential skill, ensuring your electronic projects function flawlessly. Proper installation of pcb board to wire connectors enhances device reliability and performance. Using a clear guide will help you avoid mistakes and achieve professional-level results. Whether you're a beginner or experienced, these steps will set you up for success. Let’s make the process of working with pcb board to wire connectors simple and enjoyable for you!

Key Takeaways

Gather all necessary tools and materials before starting to ensure a smooth installation process.

Prepare your PCB board by cleaning it and checking for damage to ensure strong connections.

Use a wire stripper to expose wire ends and tin them with solder for better connectivity.

Follow a step-by-step guide for connecting wires to the PCB and securing connectors properly.

Test all connections with a multimeter to ensure functionality before powering on your project.

Regularly inspect and maintain your connections to prolong the life and reliability of your projects.

Practice soldering techniques on scrap materials to build confidence and skill before working on important projects.

Tools and Materials You’ll Need

Before starting, collect all tools and materials first. Having everything ready makes the job easier and faster. Here’s what you need.

Important Tools for PCB Board to Wire Connectors

To work with PCB board to wire connectors, you need good tools. These tools help connect parts correctly and make your work better. Here’s a list:

Soldering Iron: This tool helps join wires strongly.

Wire Strippers and Cutters: Use these to remove wire covers and cut wires.

Crimping Tool: This secures wires into crimp connectors tightly.

Tweezers: Small tweezers help hold tiny parts easily.

Magnifiers: A magnifying glass helps you see small details clearly.

Anti-Static Mat with Wrist Strap: This stops static electricity from damaging parts.

Solder Removal Tools: Fix mistakes or remove solder using these tools.

Damp Sponge: Clean the soldering iron tip with this sponge.

These tools will make your work simple and neat.

Materials Needed for Circuit Boards

You also need certain materials for mounting circuit boards. These items help create strong connections that last long. Prepare these things:

Wire Connectors: Pick connectors that fit your project needs, like crimp types.

Wires: Choose wires of the right size and coating for your task.

PCB Board: Make sure it’s clean before starting your work on it.

Solder: Use good-quality solder for solid connections between parts.

Workspace Setup: Work in a clean, bright area with fresh air. This keeps you safe while working.

With these materials ready, you can confidently mount circuit boards!

Getting Ready

Before starting, make sure everything is prepared. Good preparation helps avoid mistakes and makes the process easier. Let’s split this into two simple parts.

Getting the PCB Board Ready

First, check your PCB board for damage or dirt. A clean board is important for success. Use a soft brush or air to remove dust. If there’s grease, clean it with alcohol and a lint-free cloth.

Then, look at the solder pads on the board. Make sure they are clean and shiny. If needed, lightly polish them with fine sandpaper or a fiberglass pen. This helps solder stick better and makes strong connections.

Next, find where your components will go on the board. Use your circuit diagram to guide you. Mark these spots if needed to stay organized during installation. Also, check that connectors align properly with PCB holes.

Lastly, set up your workspace. Work in a bright area with fresh air. Use an anti-static mat to protect the PCB from static electricity. Wear an anti-static wrist strap to keep parts safe from damage.

Getting Wire Connectors Ready

Pick wire connectors that fit your project needs well. Make sure they match your wires and PCB specifications, like crimp connectors for strong connections.

Remove insulation from wire ends using a wire stripper tool. Expose about 1/4 inch of wire but don’t harm the strands inside. Add solder to these ends to make them stronger and easier to connect.

Check connectors for any problems like dirt or rust. For crimp connectors, ensure you have the right crimping tool for them. If using screw-type connectors, make sure screws work correctly and tighten easily.

Finally, prepare an enclosure if needed for your project setup. Ensure it has enough space for both PCB and connectors inside it neatly. Align mounting holes properly so everything fits well together.

Step-by-Step Installation Guide

Installing pcb board to wire connectors needs care and focus. Follow these steps for smooth work and strong results.

Connecting Wires to the PCB Board

First, get the wires ready. Use a wire stripper to remove 1/4 inch of insulation. Be gentle so you don’t break the wire strands. After stripping, add a little solder to the bare ends. This step, called tinning, makes wires stronger for better connections.

Next, find the right solder pads on your PCB board. Check your circuit diagram to know where they go. Hold the tinned wire on the pad with tweezers. Heat both the pad and wire together using a soldering iron. Add solder until it flows well and sticks firmly. Take away the iron and let it cool by itself. Do this for all wires.

Expert Tip: "Placing parts on printed circuit boards needs careful work for good connections."

Check each joint again to make sure there are no weak spots or loose wires. Strong joints are key for making your project work well.

Securing the Wire Connectors to the PCB

After attaching wires, secure your connectors next. For crimp connectors, push wires into their terminals first. Use a crimping tool to lock them tightly in place. Make sure they stay firm and don’t slip out.

For screw-type connectors, put wires into terminals and tighten screws carefully. Don’t over-tighten as it might harm wires or connectors.

Line up connectors with holes on your PCB board properly. Attach screws or clips gently to hold them steady in place. This keeps everything stable when running later.

Testing the Installation for Continuity and Functionality

When done securing parts, test if everything works right! Use a multimeter tool to check each connection’s flow (continuity). Touch probes at both ends of every wire; ensure circuits complete fully without breaks.

Turn on power now; watch if all parts function fine together! If something doesn’t work well yet? Look back at solder points or crimped areas again till fixed perfectly!

By following this easy guide, you’ll learn how-to connect things neatly while testing setups too! These steps help keep printed circuit boards working great always!

Solving Common Problems

Even if you prepare well, problems can still happen. Knowing how to spot and fix them keeps your project working. Let’s look at some common issues and their fixes.

Fixing Weak Connections

Weak connections can make circuits stop working right. You might see loose wires or parts not working sometimes. Check all solder joints first. If the solder looks dull or bumpy, it’s weak. Heat the joint again with a soldering iron and add a little more solder to fix it.

For crimp connectors, check if wires are held tightly. Loose crimps can stop electricity from flowing well. Use a crimping tool to press the wire firmly into place. For screw-type connectors, make sure screws are tight but don’t damage the wire.

Helpful Tip: Use a multimeter to test connections. It shows if electricity flows properly through each part.

Solving Short Circuits or Wrong Wire Placement

Short circuits happen when wires touch by mistake or extra solder connects pads together. Wires in the wrong spots also cause problems in circuits. Look closely at your PCB for extra solder bridges. Use a desoldering tool or braid to remove extra solder carefully.

If wires are in the wrong places, check your circuit diagram again. Make sure each wire goes where it should be connected. If there’s an error, remove the wire and attach it correctly this time. Keep wires tidy so they don’t touch accidentally.

Reminder: Keep your workspace clean! Dust or dirt can mess up your work and cause mistakes.

Avoiding Overheating While Soldering

Too much heat during soldering can harm parts of your PCB or connectors. To prevent this, use a soldering iron with adjustable heat settings. Set it to match the type of solder you’re using and work quickly but carefully.

If you smell burning or see discoloration, stop right away! Let things cool before continuing again later on. Clean your iron tip often with a damp sponge for better heat control while working.

When setting up circuit boards, always use an anti-static mat and wrist strap too! These keep delicate parts safe from static shocks that could ruin them forever.

Quick Tip: Practice on old materials before starting real projects! This helps you get better at soldering without risking important pieces.

By solving these problems step by step, you’ll make stronger connections and better projects every time! Troubleshooting is key for anyone learning about PCB board wiring skills.

Smart Tips and Tricks

When using PCB board to wire connectors, good habits help. They make your projects work better, stay safe, and last longer. Let’s look at some simple tips to improve your skills.

Easy Steps for PCB Project Success

Start with a clear plan for your project. Use a trusted guide to organize your steps. Gather all tools and materials before you begin working. This saves time and avoids mistakes.

Label wires and connectors to keep things clear. Use colored wires or small labels to know what goes where. Keep your workspace neat and clean for better focus and fewer errors.

Work slowly and carefully. Connect one wire or part at a time, then test it before moving on. Rushing can cause mistakes that are hard to fix later. Take your time for the best results.

Quick Tip: "Check your circuit diagram twice before soldering anything."

Staying Safe While Working on Circuit Boards

Safety is very important when working with circuits. Wear goggles to protect your eyes from hot solder splashes. Use an anti-static wrist strap to keep parts safe from static shocks.

Make sure there’s fresh air in the room while you work. Solder fumes can be harmful if breathed in too much. Use a fan or open a window nearby for ventilation. Don’t touch hot tools or parts—they can burn you quickly!

Keep flammable items away from where you’re soldering. Put tools back safely after use, and unplug the soldering iron when done.

Important Reminder: "Never leave a hot soldering iron alone—it’s dangerous!"

Keeping Your PCB Connections Strong Over Time

Take care of your connections so they last longer! Check them often for loose wires, rust, or damage like discoloration.

Clean dust off the PCB board with a soft brush or air spray now and then. For connectors, use special cleaners to remove dirt so electricity flows well.

Store finished projects in cool, dry places away from moisture that could cause problems like rust or shorts. If something moves often, secure its wires tightly so they don’t break over time.

Helpful Advice: "Inspect connections every few months if used regularly."

By following these easy tips, you’ll build strong projects that work great! With regular care, your designs will stay reliable for years ahead.

Now you know how to install PCB boards easily. Getting tools ready and testing connections are important steps. Following this guide helps your projects work better and last longer. Practice often to get better and feel more confident. Soon, you’ll be great at this skill and use it in new designs. Begin your next project now and notice how helpful clear steps are!

FAQ

What do PCB board to wire connectors do?

These connectors link your circuit board to other parts or devices. They make sure electricity flows well, helping your projects work smoothly. They also make it easy to build, fix, or upgrade your setup.

Can beginners install PCB board to wire connectors?

Yes, they can! This guide is perfect for beginners. Follow the steps to prepare, connect, and test with ease. Start with small tasks and practice often. You’ll get better quickly!

What tools are needed for this task?

Here are the main tools you’ll need:

Soldering iron for attaching wires.

Wire strippers to remove wire covers.

Crimping tool for crimp-style connectors.

Tweezers for handling tiny parts.

Multimeter to check if connections work.

These tools make the job simpler and give great results.

How do I pick the right wire connectors?

Choose connectors that fit your project’s needs. Crimp ones are strong and last long. Screw-type ones let you adjust easily. Always check if they match your PCB and wires before starting.

Why should wires be tinned first?

Tinning makes bare wire ends stronger by adding solder. It helps electricity flow better and keeps wires from splitting apart during use. This step ensures a good connection on the PCB.

What if my connections fail?

Don’t worry—check these common problems:

Look at solder joints for weak spots or loose ends.

Check for extra solder causing short circuits.

Make sure wires match their correct spots in the diagram.

Fix each issue carefully, one step at a time.

How can I avoid overheating while soldering?

Use a soldering iron with heat settings you can adjust. Set it based on your solder type and work steadily but not too slow. Clean the tip often so it heats properly without burning anything.

Should I test connections after installing them?

Yes! Testing is very important to ensure everything works right. Use a multimeter to see if electricity flows through all parts correctly. Only turn on power once all checks are done safely.

How do I keep PCB board to wire connectors in good shape?

Take care of them regularly! Clean off dust or dirt from both boards and connectors often. Look out for rust or loose wires too. Store finished projects somewhere dry and cool to avoid damage from moisture.

Where can I get more help if needed?

If stuck, don’t hesitate—ask questions! Leave comments below or visit online forums for advice from others who’ve done this before. Remember, even experts started as learners like you!

See Also

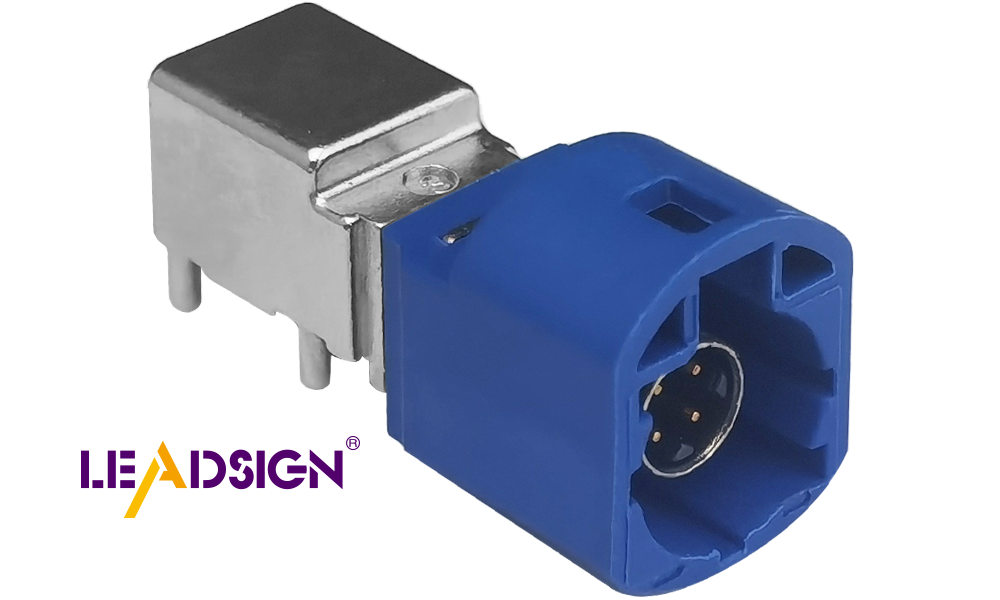

Exploring FAKRA Connectors: Key Benefits for PCB Use

Fakra Connectors Explained: Benefits, Uses, and Setup Advice

Why FAKRA PCB Connectors Are Essential for Automotive Needs

Understanding HSD Connectors: A Complete Overview

FAKRA PCB Connectors: Vital Role in Automotive Communication