How to Properly Install Car Harness Connectors at Home

Car harness connectors are important for car wiring systems. They help connect parts like stereos and sensors easily. You can also use them to connect to repair tools. But installing them wrong can be dangerous. Loose wires or wrong parts might cause fires or shocks. Installing them correctly keeps your car working and keeps you safe.

Key Takeaways

Use proper tools like soldering irons and wire cutters. This helps make the car harness connectors safe and secure.

Set up your workspace neatly before starting. This prevents errors and makes the job easier.

Check the connections using a multimeter or tester. This ensures the wiring works and helps find problems early.

Tools and Materials for Installing Car Harness Connectors

Important Tools for Wiring Harness Work

To install car harness connectors, you need proper tools. These tools make the job easier and safer. Here’s what you’ll need:

A soldering iron joins wires firmly and neatly.

Wire cutters and crimpers cut wires and attach connectors.

A helping hand tool holds wires steady while you work.

Dielectric grease protects wires from damage during installation.

A strong workbench gives space to organize your wires.

These tools help make your wiring safe and secure.

Materials Needed for Car Harness Connectors

You also need certain materials to finish your wiring project. These include:

Connectors, terminals, and wires for the harness.

Cable ties, sleeves, and shrink tubing to protect wires.

Electrical tape to cover and secure loose ends.

These materials help you build a strong and tidy wiring system.

Extra Tools for Faster Work

To save time, you can use extra tools. These tools make the process quicker:

Wire strippers remove insulation from wires easily.

A utility knife or razor blade can strip wires too.

A lighter softens insulation for easy removal.

These tools aren’t required but can make your work faster and simpler.

Preparation Steps for Wiring Harness Installation

Safety Precautions Before Starting

Before starting, make sure you stay safe. Check all wires to ensure they are covered to avoid short circuits. Place wires carefully so they don’t get in the way of moving parts. Always use the right tools and follow instructions to avoid damage.

Here are some extra tips to remember:

Leave space around the harness to avoid squeezing it.

Keep plugs of the same color separate to avoid mistakes.

Place connectors where you can reach them later.

Don’t bend the harness too much or let harmful stuff touch it.

These steps help make the installation safe and smooth.

Preparing the Vehicle and Work Area

A clean workspace helps you work better. Park your car in a bright spot. Disconnect the battery to avoid getting shocked. Clear away trash or mess to keep the area safe.

Inside the car, take off panels that block the wires. Use a sturdy table to organize your tools and materials. This setup helps you stay focused and work faster.

Organizing the Wire Harness Assembly

Good organization makes the job easier. Use strong materials to avoid problems later. Tools like cutters, crimpers, and soldering irons help you work neatly. Keep your area clean to avoid mistakes.

Follow the wiring plan carefully. Arrange wires neatly and secure them with ties or sleeves. Test the harness before installing to find and fix any problems. This ensures the system will work well when done.

Step by Step Guide to Installing Car Harness Connectors

Getting Wires Ready and Stripping Them

Prepare wires before starting the installation. Stripping wires properly helps them connect well. Follow these steps:

Use a wire stripper to take off a small part of the wire's cover.

Cut wires to fit the terminal size. This stops loose connections.

Work carefully during this step. Well-stripped wires last longer and prevent electrical problems.

Crimping Connectors Tightly

Crimping connects the terminal to the wire securely. Use a crimping tool to press the terminal onto the wire firmly. Make sure the terminal fits tightly but doesn’t harm the wire. A good crimp keeps the connector from coming loose. Test it by gently pulling the wire. If it stays, the connection is strong.

Attaching Wires to the Harness

When attaching wires, focus on safety and proper setup. Keep these tips in mind:

Separate plugs with the same color to avoid mistakes.

Place connectors where you can reach them later.

Extend engine wires slightly to handle shaking and avoid loose ends.

Protect wire joints from oil, water, and dirt for long-lasting use.

A neat connection helps the harness work correctly.

Securing and Routing the Harness

Routing wires correctly keeps them safe from harm. Don’t hide wires under carpets where they can get damaged. Instead, run them along the car’s edges. Use covers like tubes or sleeves to protect the harness. Secure wires with ties or clips to stop them from moving.

When passing wires through the firewall, use rubber rings to prevent damage. Keep wires away from heat sources by at least six inches. Wrap wire bundles neatly with tape or ties for easy checking later. Following these steps keeps the harness safe and tidy.

Testing and Troubleshooting the Wiring Harness

Checking Connections for Continuity

Testing makes sure your wiring harness works properly. Use these tools to check connections:

Multimeter: This tool measures voltage, current, and resistance. It finds wiring problems.

Continuity Tester: A simple tool that shows if electricity flows between two points. It lights up when the path is complete.

Wire Harness Tester: A special device that checks for breaks, insulation issues, and short circuits.

To test, connect the tool to the harness and follow its steps. If a break is found, check wires and connectors for damage or loose ends.

Finding and Fixing Common Problems

Problems can happen during installation. Here’s a table of common issues and fixes:

Problem | Solution |

|---|---|

Wires not prepared correctly | Cut and strip wires carefully. Use tools to avoid mistakes. |

Wires placed in wrong spots | Use boards to check for missing or misplaced wires. |

Labels are unclear | Make clear labels to avoid confusion while assembling. |

Bad crimping or soldering | Use the right tools and methods for strong connections. |

Missing or wrong parts | Check instructions to ensure all parts are correct. |

Tying wires too tight or loose | Tie wires firmly but not too tight to avoid damage. |

Fixing these problems quickly helps your harness work well.

Keeping the Installation Reliable for a Long Time

To make your harness last longer, follow these tips:

Place the harness on stable paths to stop extra movement.

Secure it with ties or clamps to avoid rubbing or shaking.

Add strain relief to protect wires and connectors from stress.

Cover the harness with tubing to guard against spills or chemicals.

Use good-quality materials that match the car’s environment.

These steps keep your wiring harness safe and working for years.

Tips for a Successful Wire Harness Assembly

Best Practices for Smooth Installation

Follow these tips for an easy installation:

Use good-quality connectors and tools to avoid damage.

Label wires clearly before starting to prevent confusion.

Plan the wiring layout ahead to save time and avoid mistakes.

Keep wires tidy with ties or sleeves for safety and easy fixes.

Test the harness often to find and fix problems early.

Tip: Work in a clean, bright area to stay focused and avoid errors.

Mistakes to Avoid During the Process

Avoid these common errors to save time and effort:

Using bad or wrong connectors can cause wiring problems.

Not checking pins may lead to weak connections.

Skipping proper tools can harm wires and connectors.

Forgetting to test might leave hidden issues unfixed.

Reusing single-use connectors often causes failures.

Stripping wires wrong can damage the wiring.

Picking the wrong size connectors stops circuits from working.

Twisting too much or removing too much cover can expose wires.

Note: Check your tools and materials before starting to avoid delays.

Maintenance Tips for Wiring Harness Longevity

Take care of your harness to make it last longer:

Arrange wires neatly to avoid damage and for easy access.

Twist insulation properly to stop shorts and protect wires.

Handle breakouts gently and add strain relief to protect them.

Route wires on safe paths to reduce wear and movement.

Use ties or clamps to stop rubbing on sharp edges.

Add strain relief at connections to reduce stress on wires.

Shield the harness from chemicals with strong materials.

Reminder: Check wires often for damage. Fixing small issues early prevents big problems later.

Putting in car harness connectors the right way keeps your car's wiring safe and working well. Go through each step carefully to avoid errors. Covering wires properly keeps them safe from heat and water. Fastening and placing wires neatly stops problems like short circuits. Checking connections early helps find and fix issues. Take your time and stay focused to finish the job successfully.

FAQ

What does a car harness connector do?

It connects electrical parts in your car. This helps systems like GPS, sensors, and radios work together properly.

Should I use old connectors for new wiring?

No, old connectors might not work well or could fail. Always pick new ones for safe and strong connections.

How can I check if my harness works?

Use a multimeter or tester to check connections. Make sure wires are secure, covered, and not broken.

See Also

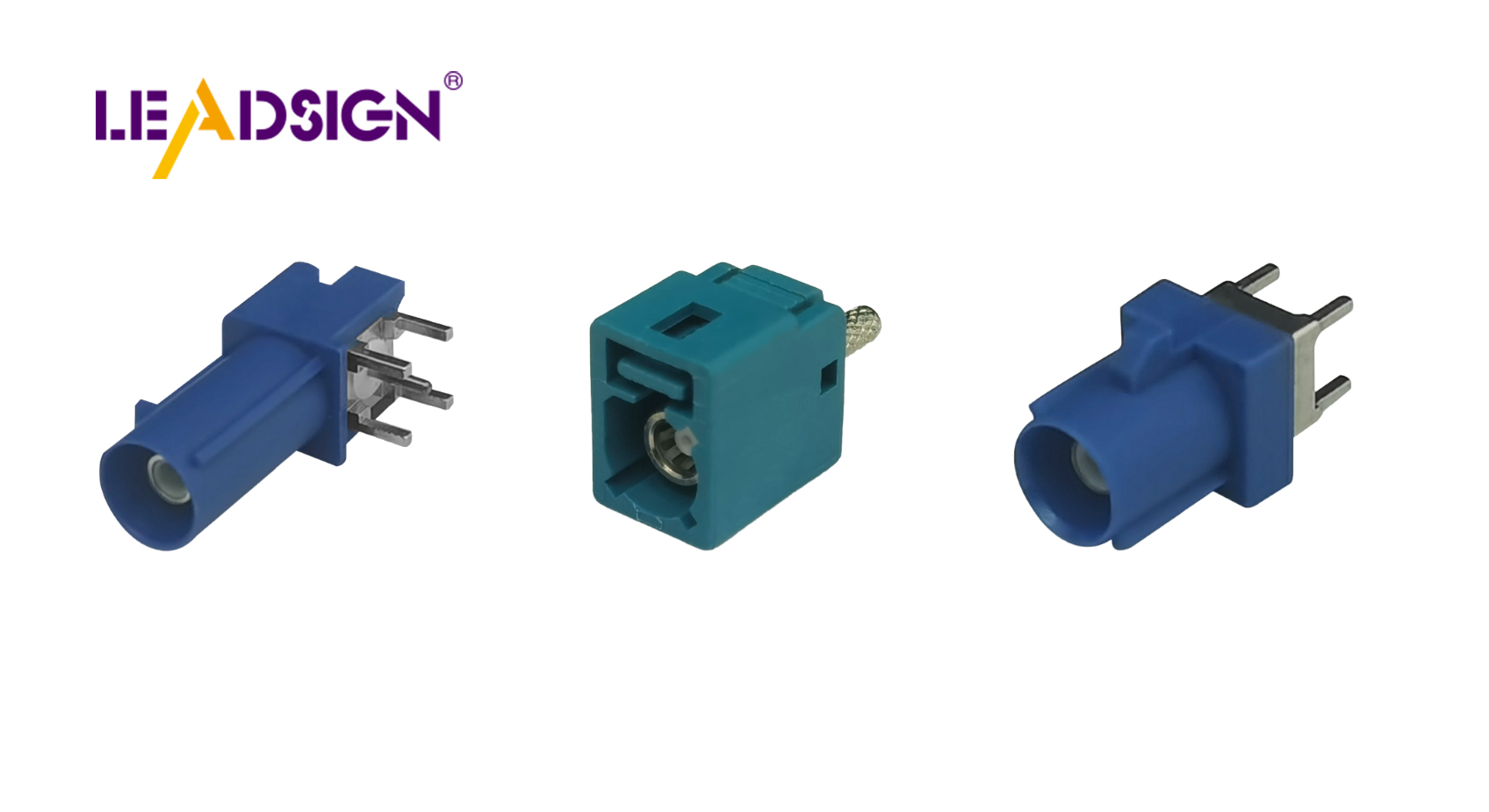

Understanding HSD Connectors Used in Cars Today

A Comprehensive Overview of Fakra Connectors for Honda

Why HSD Connectors Matter in Automotive Engineering