How to Install Automotive Wiring Connector Types for Beginners

Automotive electrical connectors types are crucial for your car's electrical system. They facilitate the smooth transmission of electric signals and power between various components. Proper installation of these connectors is essential for maintaining the safety and optimal functionality of the vehicle. Incorrectly installed connectors can lead to electrical issues, impacting the performance of your car. Understanding the various automotive electrical connector types empowers you to make informed decisions during installation. These connectors serve as the foundation of car systems, linking components such as lights and sensors to ensure the efficient and safe operation of your vehicle.

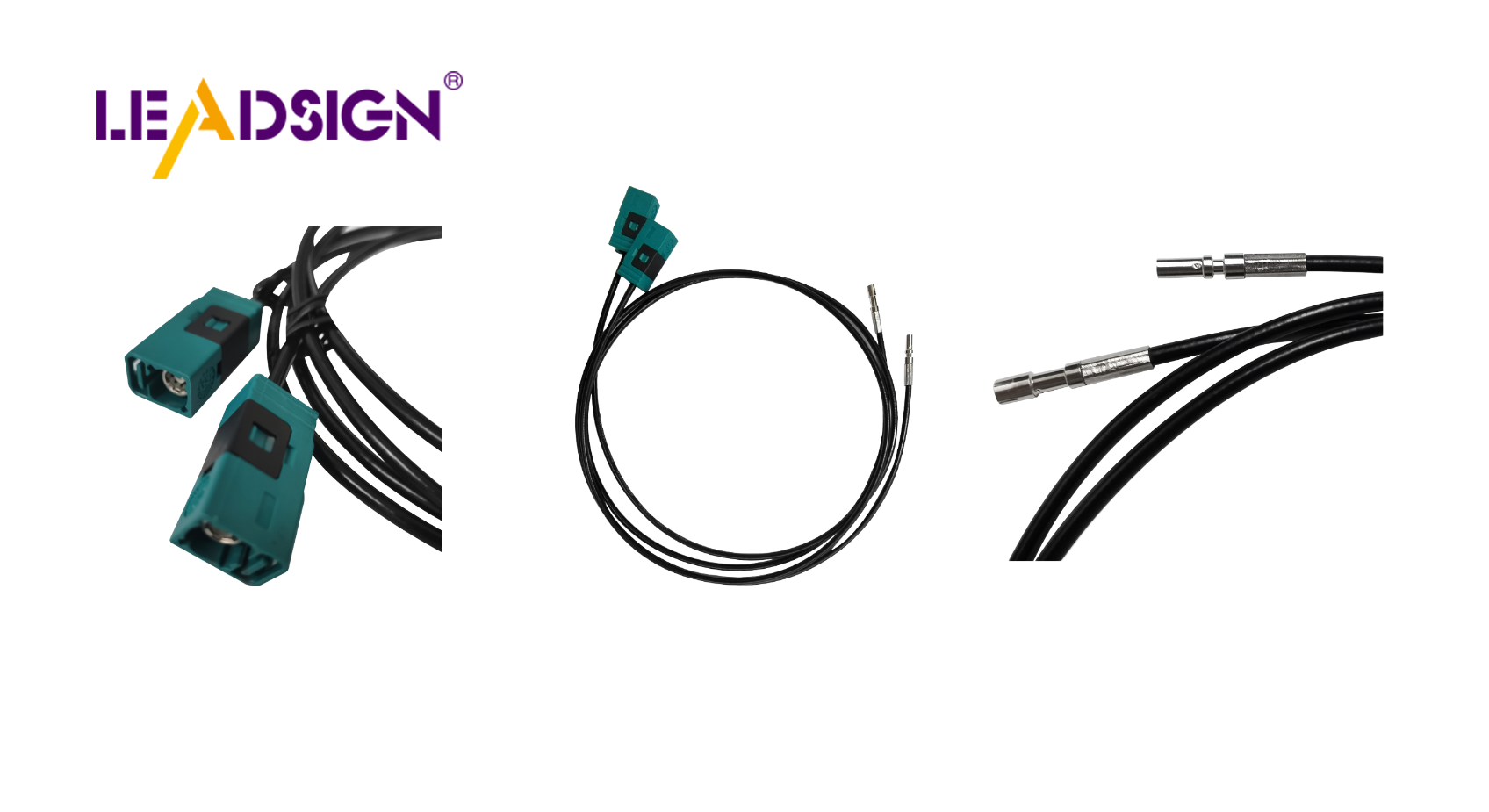

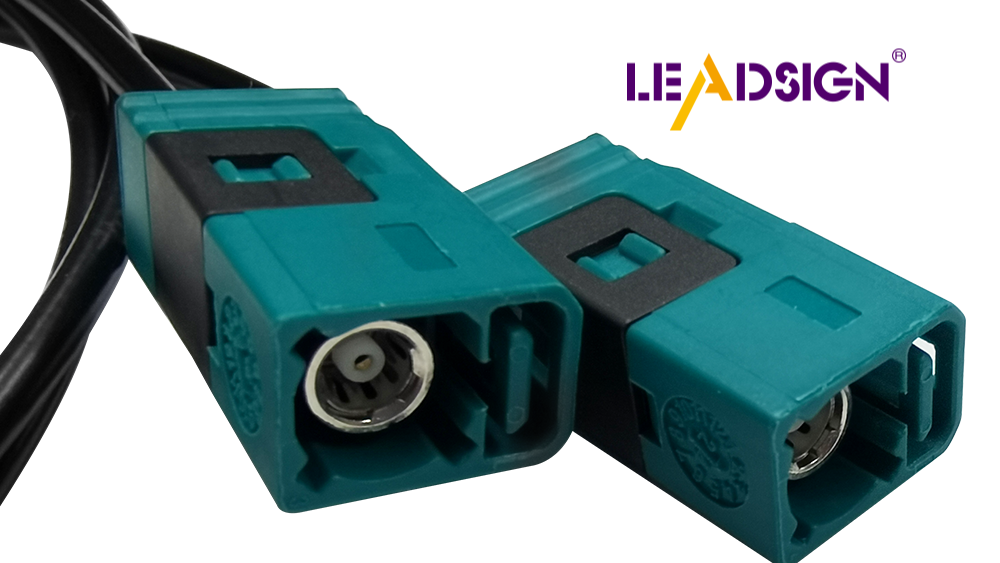

Understanding Automotive Electrical Connectors Types

Automotive electrical connectors types are important for your car's electric system. They come in different shapes, each made for a special job. Knowing these helps you pick the right one.

Overview of Automotive Electrical Connectors Types

Blade Connectors

Blade connectors are flat metal pieces that fit into slots. They are easy to use and reliable, often found in fuse boxes where strong connections matter.

Bullet Connectors

Bullet connectors look like small cylinders fitting into sockets. They make it simple to connect or disconnect wires, useful for trailer wiring.

Butt Connectors

Butt connectors link two wires end-to-end. They're great for making wires longer or fixing broken ones by crimping them together.

Ring and Spade Terminals

Ring and spade terminals attach wires to screws or studs. The ring goes around the screw tightly, while the spade can be removed easily without unscrewing fully.

Tools Required for Installation

To install automotive electrical connectors types, you need specific tools. These tools help make sure your connections stay strong.

Wire Strippers

Wire strippers take off wire insulation without harming the inside part, getting it ready for crimping or soldering.

Crimping Tools

Crimping tools press connectors onto wires firmly. A Sargent Crimper is popular for American car connections, making them strong and lasting.

Heat Shrink Tubing

Heat shrink tubing adds extra protection to connections. After crimping, put it over the joint and heat it so it seals tight against water and stress.

Multimeter

A multimeter checks voltage, current, and resistance in circuits. It tests if your connections work well and safely after installation.

By learning about these automotive electrical connectors types and using the right tools, you can handle car wiring projects confidently. Good installation boosts performance and keeps you safe on roads.

Step-by-Step Installation Guide

Installing automotive electrical connectors types needs careful work. This guide will help you make sure everything connects well.

Preparing the Wires

Before connecting, get the wires ready. This is important for success.

Stripping the Wire Insulation

Pick the Right Tool: Use wire strippers to take off insulation. These tools keep wires safe.

Measure How Much: Take off about 1/4 inch of insulation from wire ends. This shows enough wire for a good link.

Check the Wire: Look at the wire after stripping it. Make sure there are no cuts or marks.

Choosing the Right Connector

Find the Connector Type: Pick the right automotive electrical connectors types for your job. Blade, bullet, and butt connectors do different things.

Think About Moisture: In wet places, use weatherproof connectors. They stop rust and last longer.

Match Wire Size: Make sure connector fits wire size right. Wrong size can cause bad links and problems later.

Attaching the Connector

After wires are ready, attach connector well.

Crimping the Connector

Put Wire in Place: Push stripped wire into connector snugly.

Use Correct Tool: Choose crimping tool for your connector type. Good tools make strong crimps.

Press Hard Enough: Squeeze crimper tightly to hold wire firm in place.

Expert Testimony: "Most including myself are in the crimp camp, it's key to have a good crimping tool and terminal type." - Anonymous User, Automotive Wiring Expert

Securing with Heat Shrink Tubing

Slide Tubing On First: Before crimping, put heat shrink tubing over wire to protect connection later.

Heat It Evenly: Use heat gun on tubing evenly so it seals tight around connection.

Look for Gaps: Check if tubing fits well against both wire and connector to block moisture and stress.

Testing the Connection

After connecting, test to see if it works right.

Using a Multimeter

Set Multimeter Up: Set multimeter to check continuity; this checks electricity flow through connection.

Test Connection Now: Put probes on each side of connection; a beep means it's working fine.

Check Voltage Too: Make sure voltage is what you expect; this shows connection is good inside too.

Ensuring a Secure Connection

Look at Physical Linkage: Pull wires gently; they should stay put if secure enough.

Redo Crimp If Loose: If loose feeling happens, re-crimp it tighter again for safety's sake!

Final Visual Checkup: See if any wires show or gaps exist in tubing; fix these before finishing up installation task!

By doing these steps carefully, you can install automotive electrical connectors types confidently! Good prep plus testing keeps car's electric system safe always!

Common Mistakes and Troubleshooting

When putting in automotive electrical connectors, you might make mistakes. Spotting these early helps save time and makes sure connections are strong.

Avoiding Common Errors

Incorrect Crimping

Crimping is key to attaching connectors to wires. If done wrong, the connection can be loose or fail. Always use the right crimping tool for your connector type. Press hard enough to secure the wire to the connector.

Tip: "Most including myself are in the crimp camp, it's key to have a good crimping tool and terminal type." - Anonymous User, Automotive Wiring Expert

Using the Wrong Connector Type

Picking the wrong connector can cause problems or damage. Each one has a job, so match it with what you need. Use weatherproof connectors where there's moisture. This stops rust and keeps connections lasting longer.

Troubleshooting Connection Issues

Even if careful, problems can happen. Knowing how to fix them is important.

Identifying Poor Connections

Bad connections come from wrong crimping or connectors. Signs include flickering signals or no power at all. Use a multimeter to check if electricity flows through well. No beep means something's wrong.

Fixing Loose or Faulty Connectors

If a connector is loose or bad, act fast. Take off the connector and look for damage. If okay, strip wire again and re-crimp with right tool. Tug wire gently; if it stays put, problem's fixed.

Insight: Handling delicate cables needs skill when working with connectors. Be gentle during installation to avoid harm.

By knowing these mistakes and fixes, you make wiring projects better. Good setup keeps your car's electric system safe and working well.

Now you know how to install car wiring connectors. This means learning about connector types, getting wires ready, and making sure connections are strong. Practice is important as you get better at this. Mistakes might happen, but they help you learn. As you feel more sure of yourself, try harder car wiring projects. These will teach you more and make your car work better. Keep trying new things and learning, and soon you'll be great at car wiring.

See Also

A Beginner's Overview of HSD Connectors for Automotive

An In-Depth Look at HSD Connectors in Automotive

Navigating Ford Fakra Connectors: A How-To