How to Install Automotive Wire Connectors: A Step-by-Step Guide

In car electronics, good wire connections, including various automotive wire connectors types, are very important. They keep your car safe and working well. More cars now have smart systems, so good wiring is needed. Wire connectors are useful because they last long and are easy to use. They keep wires connected safely, which is important for smart car features. To begin, you need some basic tools and materials. Different types of wire connectors, including automotive wire connectors types, help make the job smooth.

Tools and Materials Needed

To start installing automotive wire connectors, you need some tools and materials. Let's list them:

Important Tools

Wire Strippers

Wire strippers take off the wire cover without harm. Pick one that matches your wire size. This gives a neat strip.

Crimping Tool

A crimping tool connects wires firmly. It squeezes to make a strong hold. Use the right size for tight connections.

Heat Gun

A heat gun shrinks tubing over wires. This protects from water and damage. It's useful for making wiring last longer.

Needed Materials

Wire Connectors

Wire connectors, like automotive wire connectors, keep connections safe. Choose based on your needs and wire size.

Heat Shrink Tubing

Heat shrink tubing adds protection. It seals out water and dirt. Use with a heat gun for best results.

Electrical Tape

Electrical tape gives extra safety. Wrap it around wires for more insulation and strength. It's an easy way to secure your work.

By having these tools and materials, you're ready for any car wiring job. The right gear makes work easier and better.

Preparing the Wires

Getting your wires ready is a crucial step in installing automotive wire connectors. Let's dive into how you can do it right.

Stripping the Wire Insulation

Before you connect wires, you need to strip off the insulation. This exposes the metal wire inside, which is necessary for a good connection.

Choosing the Right Length

First, decide how much insulation to remove. You don't want to strip too much or too little. Usually, about half an inch is enough. Check your connector's instructions for the exact length. This ensures a snug fit.

Proper Technique for Stripping

Use your wire strippers for this task. Place the wire in the correct slot on the stripper. Squeeze the handles and pull gently. The insulation should come off cleanly. Avoid nicking the wire itself. A clean strip makes for a better connection.

Inspecting the Wire

After stripping, take a moment to inspect the wire. This step helps you catch any issues before they become problems.

Checking for Damage

Look closely at the exposed wire. Make sure there are no cuts or frays. Damaged wires can lead to poor connections or even short circuits. If you find any damage, cut the wire back and strip again.

Ensuring Cleanliness

Dirt or grease on the wire can interfere with the connection. Wipe the wire with a clean cloth if needed. A clean wire ensures a strong and reliable connection.

By preparing your wires properly, you set the stage for a successful installation. These steps might seem small, but they make a big difference in the quality of your work.

Installing the Wire Connectors

Your wires are ready. Let's put on the connectors. This makes sure they stay connected well.

Picking the Right Connector

Choosing the right connector is very important.

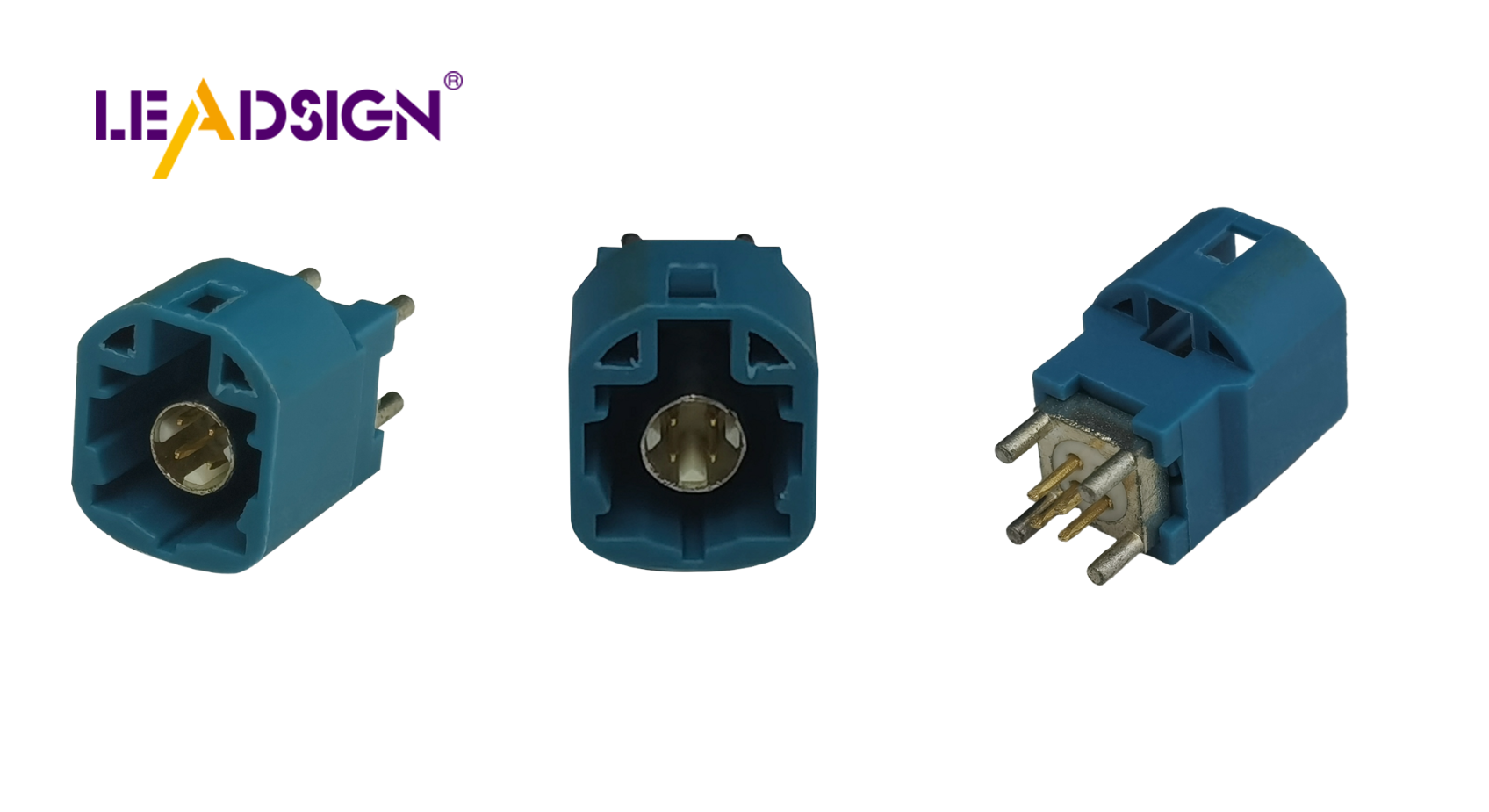

Types of Automotive Wire Connectors

There are different types of wire connectors. Each one does something different. Butt connectors join two wires. Ring connectors attach to a screw or stud. Pick what you need for your job.

Matching Connector to Wire Size

Make sure the connector fits the wire size. Check the package to see if it matches. Wrong sizes can cause bad connections. A good match makes it fit snugly and work well.

Putting on the Connector

Now, attach the connector to the wire.

Inserting the Wire

Put the stripped wire into the connector. Push until it hits metal inside. This makes a good connection. Make sure it's in all the way before you continue.

Crimping the Connector

Use a crimping tool to secure it. Put it in and squeeze tight. The crimp should hold strong so it doesn’t slip out.

Making Sure It's Secure

After attaching, make it more secure.

Using Heat Shrink Tubing

Slide heat shrink tubing over it. Use a heat gun to shrink it down. This keeps water and dirt out and makes it stronger.

Wrapping with Electrical Tape

Wrap electrical tape around for extra safety. It adds insulation and holds everything together better.

By doing these steps, your connection will last long and work well in your car's electronics.

You've learned to install car wire connectors step by step. Safe connections are very important for your car's safety and how well it works. They stop electrical problems and keep things running smoothly. Check and fix these connections often to keep them working well.

"Arrow Wire & Cable has been a big help in making sure our connections are safe and work well," says a happy customer.

By using these steps and tips, you can take care of your car's wiring easily. Keep your tools ready and always check on things for the best results.

See Also

Navigating Ford Fakra Connectors

Fundamentals of HSD Connectors for Autos

Significance of FAKRA Connectors in Auto Uses

Discovering Advantages of Fakra Auto Connectors

The Significance of Fakra Auto Connectors in Contemporary Cars