How to Install Automotive Electrical Connectors Types

Properly installing automotive electrical connectors is essential for maintaining the safety and reliability of your vehicle. There are various automotive electrical connectors types, each designed for specific applications within a car. To effectively utilize these connectors, you will need basic tools and materials. Manufacturers rigorously test these connectors to ensure they function correctly and meet industry standards. By understanding the different types of connectors, you can make informed choices and ensure your vehicle operates smoothly.

Tools and Materials Needed

To put in automotive electrical connectors, you need the right tools. These make sure your work is safe and works well.

Important Tools

Wire Strippers

Wire strippers take off the plastic cover from wires. They do this without hurting the metal inside. Pick one that fits your wire size. This tool gets wires ready to connect.

Crimping Tools

Crimping tools join connectors to wires. The MSD ratcheting crimp tool is a favorite. It has parts you can change, pressing both metal and plastic at once. It makes connections look neat and fit well. A good crimper saves time and makes better work.

Multimeter

A multimeter checks voltage, current, and resistance. Use it to test if connections are good. This tool helps check your electrical system after setting it up.

Needed Materials

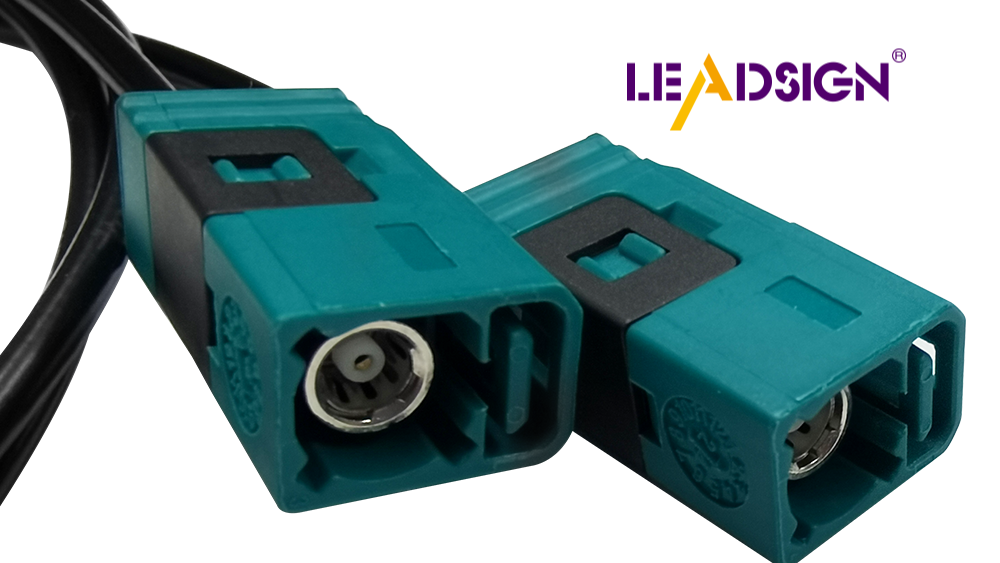

Different Connectors

Cars use many connector types. Have ones that fit your car's needs. Picking the right connector keeps things connected safely.

Electrical Tape

Electrical tape covers and protects connections. Wrap it around wires to keep out water and dirt. It's important for keeping your system working long.

Heat Shrink Tubing

Heat shrink tubing adds more protection to connections. Slide it on, heat it up, and it shrinks tight around them. This keeps them strong against weather.

With these tools and materials, you can install automotive electrical connectors easily. Each thing helps make sure your car's electric parts work safely.

Step-by-Step Installation Process

Putting in automotive electrical connectors needs care. Follow these steps for a safe connection.

Getting Wires Ready

Removing Wire Cover

First, take off the wire cover. Use wire strippers to do this without scratching the metal inside. This is important to show the wire for connecting. Only strip what you need to keep it safe.

Checking Wire Length

After stripping, look at the wire length. It should reach the connector easily but not be too long. Right length keeps things tidy and avoids problems.

Picking the Right Connector

Finding Connector Types

Find the right connector type for your job. Different automotive electrical connectors types do different jobs, like waterproof ones for wet places. Choosing right means it will fit and work well.

Matching Connector with Wire Size

Match connector with wire size (gauge). Gauge means how thick the wire is, and using a fitting connector is key for strong links. Wrong match can cause bad connections or breaks.

Joining Wires

Putting Wires in Connector

Put stripped wires into connector fully. Make sure they sit tight inside to keep a good link. This stops loose connections that might fail.

Crimping Connector

Use crimping tool to lock connector on wire. Crimping squeezes connector around wire tightly. Good crimp keeps connection strong in any condition. Practice makes perfect crimps every time.

Expert Tip: "Watch videos on making connectors and practice first. Ensure good crimps before starting." - Expert in Connectors

By doing these steps, you can put in automotive electrical connectors well. Each step helps your car's electric system stay safe and work right.

Making the Connection Safe

Keeping your car's electrical connections safe is important. It helps them last longer and work well. Follow these easy steps to make sure they stay secure.

Using Heat Shrink Tubing

Pick the Right Size: Get heat shrink tubing that fits over the connector and wire snugly. It should be a bit bigger than the connector so it fits tightly when shrunk.

Slide It On: Before you crimp, slide the tubing onto the wire. After crimping, move it over the connector to cover everything.

Heat Evenly: Use a heat gun to shrink the tubing evenly all around. This makes a tight seal that keeps out water and dirt.

Check for Gaps: Look at the tubing after shrinking for any gaps or loose spots. Good heat shrink should fit smoothly and tightly around everything.

Expert Tip: "Heat shrink adds extra protection, making connectors stronger against weather."

Adding Electrical Tape for More Safety

Wrap It Up: After using heat shrink, wrap electrical tape around it all. Start at the wire and go towards the connector, overlapping each layer a little bit.

Make It Tight: Pull the tape tight as you wrap it to stick well. This gives more insulation and safety.

Cover Everything: Be sure to cover any open wire or parts of connectors with tape. This stops dirt and water from getting in.

Check Your Work: Look at your tape job for any loose ends or gaps. A good wrap should be tight and even, giving extra security.

By doing these steps, you make your car's electrical connections stronger and safer against weather problems.

Tips and Things to Think About

When putting in car electrical connectors, focus on details. This helps you do it right. Here are some tips to help you.

Mistakes People Make

Crimping Too Much or Not Enough

Crimping joins the wire and connector. If you crimp too much, it can break things. If you crimp too little, the connection is weak. Use the right tool and press just enough.

Picking Wrong Connector Type

Wrong connectors don't fit well. They might not work right. Different connectors do different jobs, like keeping water out. Always pick the right one for your job.

Pro Tips for Doing It Right

Checking Connections Twice

After you're done, check all connections again. Make sure they are tight and in place. A quick look can stop problems later.

Keeping Connections Safe

Good insulation keeps dirt and water away from wires. Use heat shrink tubing and tape to cover wires well. This keeps connections strong for a long time.

Follow these tips to avoid mistakes when installing car electrical connectors. This way, your car's electric system will work well.

First, you learned to get wires ready. Next, pick the right connectors. Finally, make sure connections are tight and safe. These steps keep your car's electrical parts working well.

"I used them because my car needed them," said a car fan. This shows why knowing about connectors is important.

Practicing these skills makes you better at fixing cars yourself. Over time, changing old connectors or tidying up wires will feel easy. Enjoy learning and getting better at taking care of your car.

See Also

Essential HSD Connectors for Automotive Sector

Navigating Ford Fakra Connector Selection

Significance of FAKRA Connectors in Auto Uses