Master the Installation of Car Harness Connectors in 2025

Auto harness connectors are key parts of car wiring today. They help different electronic systems, like cameras and screens, work together. Installing them the right way is very important. Bad connections can cause fires, damaged batteries, or power loss. Cars in 2025 will use faster data connectors, including advanced auto harness connectors. Learning this skill now will keep you prepared.

Key Takeaways

Pick the correct tools and materials for safe connections. Use waterproof wire connectors and heat-shrink tubing to protect wires.

Follow clear steps to install the connectors properly. Crimp, secure, and test wires to avoid future problems.

Learn about new car wiring tools and trends. Knowing wireless tech and smart tools helps you stay updated.

Tools and Materials for Installing Auto Harness Connectors

Having the right tools and materials is very important. Let’s make it simple so you’re ready to start.

Tools You’ll Need

Here are the main tools to help you:

Cable Tying Tools: These keep wires neat and tight. Automated ones are useful for big projects.

Wire Harness Fixtures: These hold wires steady, making spacing easier.

Ferrules: These small rings make wire ends stronger. Be gentle when crimping to avoid damage.

Cable Tie Mounting Units: These help attach cable ties quickly and easily.

Abrasion Resistance Products: These protect wires from damage and keep them working well.

Materials for Strong Connections

Using good materials keeps your connections safe and waterproof. Here’s what you’ll need:

Waterproof Wire Connectors: These stop water and dirt from ruining your wires. Choose ones with extra locks for better safety.

Heat-Shrink Tubing: This adds waterproofing and protects wires.

High-Quality Crimp Terminals: These make strong and lasting wire connections.

Labeling Materials: Labels help you find wires easily during repairs.

New Tools and Tech for 2025

Car wiring is improving fast, and 2025 has cool updates:

New Tech | What It Does |

|---|---|

Wireless Technology | Cuts down wiring by 90%, making work faster and easier. |

Hybrid Inline Connectors | Combines power, data, and signals in one, simplifying setups. |

Better Software Tools | Programs like Harness Builder 2025 save time by automating designs. |

These tools make installing waterproof connectors quicker and more accurate. Some even measure wire lengths for you and work with smart systems. Learning about these updates will keep you ahead.

Pro Tip: Always check your tools and materials before starting. Being prepared helps you make safe and waterproof connections.

Getting Wires and Connectors Ready

Before connecting, make sure your wires and connectors are ready. This step helps everything fit and work properly. Let’s go step by step.

Checking and Cleaning Wires

Look closely at your wires. Are they broken, worn out, or rusty? If so, replace them. Bad wires can cause problems like short circuits. Clean the wires to remove dirt or grease. Clean wires make better connections.

If you’re using a wire harness, check for loose or messy wires. Straighten them and secure them with cable ties. This keeps your workspace neat and makes the job easier.

Cutting and Stripping Wires Correctly

Use wire cutters to cut wires to the right length. If they’re too short, they won’t reach. If they’re too long, they’ll get messy. Cut them neatly and precisely.

When removing insulation, don’t damage the wire strands. Broken strands make weak connections. Use a wire stripper for clean results. If working with a harness, measure each wire to match the connector’s layout.

Tip: Measure twice before cutting. It saves time and avoids mistakes.

Matching Wire Harness Plug Connectors

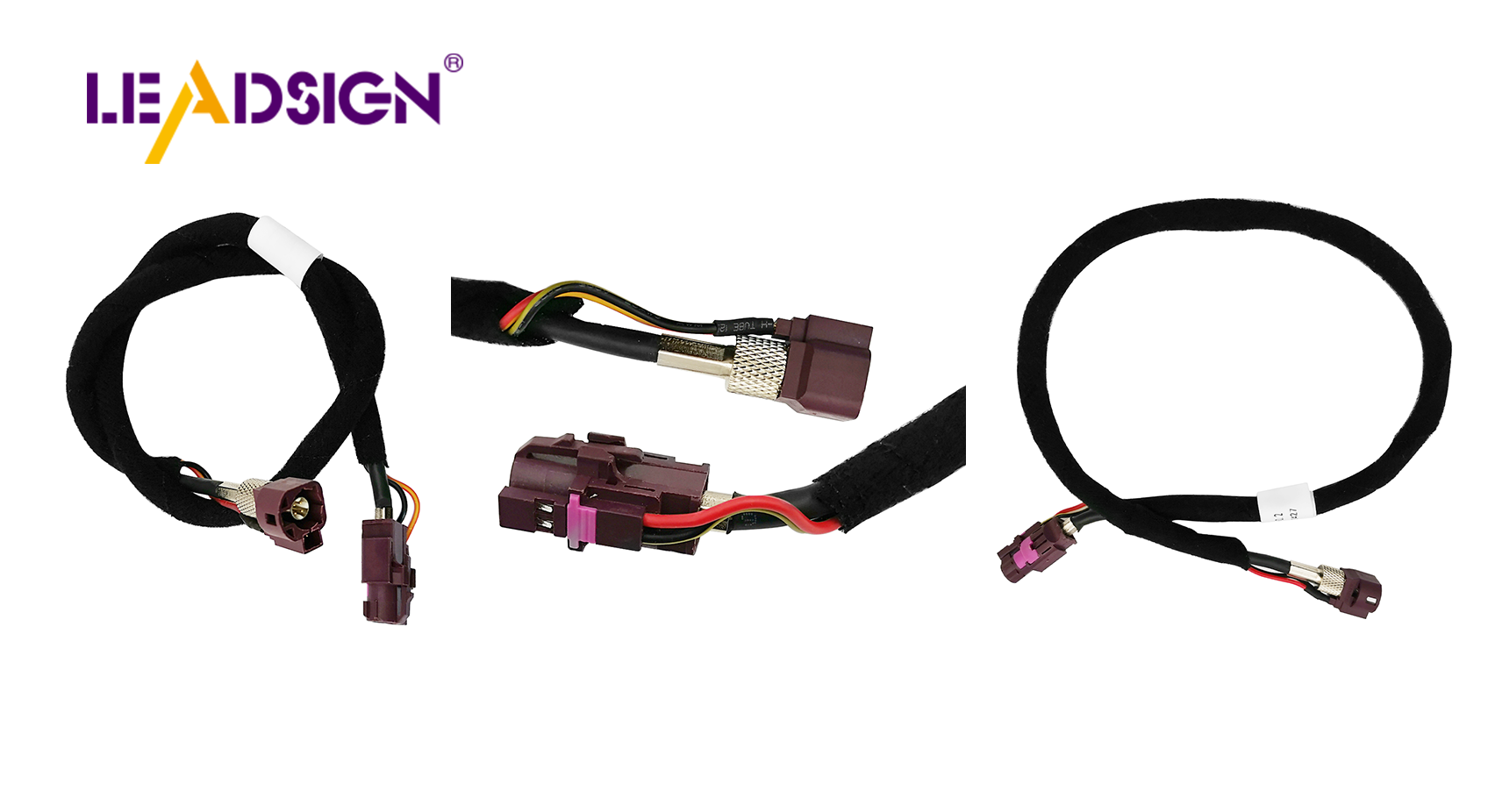

Connectors come in different types. Check that your wire harness plug connectors match your wires and devices. Look at the pin layout, size, and type. Using the wrong connector can cause system errors.

For advanced connectors like HSD connectors, make sure they work with high-speed data. These are great for modern car electronics, like cameras and screens.

Pro Tip: Keep a guide for your connectors nearby. It helps avoid mistakes and saves time.

Step-by-Step Guide to Installing a Wire Harness Plug Connector

Installing a wire harness plug connector can feel hard. Breaking it into steps makes it easier. Follow these steps for a strong connection.

Crimping the Wires for a Secure Connection

Crimping keeps wires tightly connected to the connector. Here’s how to do it:

Choose a crimp terminal that fits your wire and connector. Look for features like insulation or plating.

Use a ratchet crimping tool for better accuracy and strength.

Carefully strip the wire insulation to expose the correct length.

Put the bare wire into the crimp terminal barrel.

Place the terminal in the crimping tool and press firmly.

Check the crimp to make sure it’s tight and not damaged.

If using heat-shrink tubing, slide it over the crimp. Use a hot air gun to seal it for extra safety.

Inserting Pins into the Connector

After crimping, insert the pins into the connector housing. Match each pin to its correct slot. Push it in until you hear or feel a click. The click means the pin is locked. If you need to remove a pin later, use a special tool to avoid breaking the connector.

Securing the Connector and Testing the Connection

Once the pins are in, secure the connector with its locks. These locks stop it from coming apart by accident. Test the connection next. Use a multimeter to check if signals pass through the wires correctly.

Protecting the Wiring with Insulation or Tubing

The last step is protecting your wires. Pick the right insulation or tubing for your project:

Key Features | Uses | |

|---|---|---|

Heat Shrinkable Tubing | Blocks dust, water, and rust. | Around connections |

Corrugated Tubing | Flexible and safe for tricky wiring paths. | Complex wire setups |

Expandable Braided Sleeving | Lets air flow and handles heat well. | Organizing cables |

Slide the tubing over the wires and connectors. For heat-shrink tubing, heat it evenly to make it fit snugly. This step keeps your wire harness safe and long-lasting.

Pro Tip: Always check your work before finishing. A good connection avoids future problems.

Avoiding Mistakes and Fixing Car Electrical Connectors

Even with good tools, mistakes can still happen. Knowing how to avoid and fix problems with car connectors saves time and stress.

Common Mistakes During Installation

Errors during installation can cause bad wire connections. Here are mistakes to avoid:

Connecting parts the wrong way can break the system. Always check alignment first.

Weak crimping makes poor connections. Use the right crimping tool.

Dirty wires block electricity. Clean them before crimping for better contact.

Skipping waterproofing lets water in, causing rust or melted connectors.

Tip: Work slowly and carefully. Rushing leads to more mistakes.

Fixing Loose or Broken Connections

If something doesn’t work, stay calm. Try these steps to fix it:

Use a multimeter to check for voltage drops in wires.

Make sure ground connections are tight and working well.

Look for rust or loose wires that might break the circuit.

Fix open circuits, then test again for voltage drops.

Pro Tip: Use a high-impedance multimeter for accurate results.

How to Repair Damaged Electrical Connectors

Follow these steps to repair broken connectors:

Take out damaged wires and pins from the connector. Open the cap and lock to reach them.

Use a tool to release pins without breaking anything.

Replace or fix wires. Soldering makes strong connections, while crimping works for bigger bundles.

Cover joints with heat-shrink tubing for safety. Keep wires away from sharp edges.

Note: If replacing a connector, pick one that matches the original to avoid problems.

By following these tips, you can fix most connector issues and keep your wiring safe.

Advanced Tips and Trends for 2025

Using Smart Tools for Better Accuracy

In 2025, smart tools make installing wire harnesses easier. They save time and help you avoid mistakes. Here’s how they help:

Tools that measure wire lengths ensure wires fit perfectly.

Automation software fills in missing details in documents for you.

Advanced machines work with testers and welders for easy splicing.

Design tools share data with systems like Berrylium for teamwork.

These tools make your work simpler and more accurate. Using them keeps you ahead in the fast-changing car industry.

Adding Heat-Shrink Tubing for Stronger Wires

Heat-shrink tubing is great for protecting wires. It’s made of a material that shrinks tightly when heated. This creates a seal that blocks water, dirt, and chemicals.

Here’s why it’s useful:

It shields wires from damage and rough conditions.

It makes electrical parts last longer.

It holds connections tightly in place.

To use it, slide the tubing over the wire before heating. Then, use a heat gun to shrink it evenly. This simple step keeps your wires safe and long-lasting.

Keeping Up with New Wiring Trends

Car wiring is changing fast, so staying updated is important. In 2025, new ideas like wireless tech and eco-friendly materials are popular. For example, smaller harnesses save space. Marelli’s Wireless Battery System cuts wires by 90%, giving more room for batteries.

By learning about these trends, you’ll handle new challenges and do great work.

Pro Tip: Read industry news and join workshops to learn about updates.

Learning to install car harness connectors takes time, but it’s important. Begin by getting your tools and wires ready. Carefully follow each step, like crimping, securing, and testing. Always check your work to make sure it’s safe and strong.

Keeping up with new tools and methods helps you stay ahead. You can:

Take classes to improve your skills.

Read magazines to learn about new trends.

Go to workshops to practice hands-on techniques.

With good preparation, focus, and a desire to learn, you can handle any wiring task with confidence.

FAQ

What’s the best way to avoid loose connections?

Use the right crimping tool and double-check your work. A secure crimp ensures the wire stays in place and works properly.

How do you test if a connection is working?

Use a multimeter to check for continuity or voltage. This tool quickly confirms if your connection is solid and functional.

Can beginners handle installing car harness connectors?

Yes! Start with basic tools and follow step-by-step guides. Practice makes it easier, and you’ll improve with each project.

See Also

Why HSD Connectors Are Essential For Automotive Applications

Exploring High-Speed FAKRA-Mini Connectors In Automotive Technology

Understanding HSD Connectors: A Guide For Automotive Use