Innovations Shaping the Future of Vehicle Connectors

We depend on vehicle connectors for future transportation needs. These parts help electric cars manage high voltages safely. They also support smart driving systems and share data for entertainment. Car makers now use lighter, eco-friendly materials for connectors. This improves gas mileage, cuts pollution, and makes them last longer in tough weather.

Key Takeaways

High-voltage connectors are essential for electric and hybrid vehicles, enabling safe power transfer and supporting the growing demand for electric cars.

The shift to eco-friendly materials in vehicle connectors not only reduces pollution but also enhances performance, making cars lighter and more efficient.

Smaller, robust connectors are revolutionizing modern car designs, allowing for more technology in less space while maintaining reliability and functionality.

High-voltage connectors for electric and hybrid vehicles

High-voltage connectors are important for electric and hybrid cars. They safely move power between the battery, motor, and systems. As more cars go electric, the connector market will grow. By 2030, it may reach USD 9.14 billion. This shows the need for strong connectors for high power. But making these connectors is not easy. They need shielding to stop signal problems. Big cables also need smart designs to fit in small spaces.

Managing heat and safety issues

Handling heat is key for high-voltage connectors in electric cars. Fast charging and high power can cause overheating. New materials like Sarlink® TPVs help with heat and recycling. These are better than old materials like EPDM rubber. They work well for electric car heat needs. Cooling systems are also added to keep connectors safe and reliable.

Connectors in EV charging systems

Connectors are crucial for EV charging systems. They move power in batteries and charging ports. Fast-charging stations need better connectors for quick power transfer. Some stations now charge up to 350 kW. Smaller connector designs help stop overheating and improve charging speed. These changes make electric cars more popular. As the market grows, connectors will help improve charging and green transport.

Smaller Connectors for Modern Cars

Tiny connectors for packed car systems

Modern cars have more tech in less space. Small connectors help save room and cut weight. This matches the need for smaller, efficient car systems. Lighter designs also improve gas mileage and lower pollution.

New small connectors have tiny parts that still work well. These changes let even the smallest connectors handle complex car electronics.

Making small connectors strong and long-lasting

Shrinking connectors is tricky. They must be small but tough. Makers use special materials and smart designs to solve this. Small connectors can resist heat and shaking. This keeps them working in tough conditions.

Tiny connectors also need to keep signals clear and save power. Engineers use new ways to crimp wires and lock parts. This makes them strong without losing function.

Examples of tiny car connector parts

Some small car connectors are already in use. Mini50 connectors save half the space of older ones and resist heat well. stAK50h connectors mix signal and Ethernet in a small size, great for modern cars. PicoMQS connectors link parts like lights and steering. They resist shaking and carry up to 4 amps, working well in hard jobs.

These examples show how smaller connectors are making cars smarter and better.

Wireless Connectivity and Smart Vehicle Systems

Helping cars talk to everything around them

Wireless connectors help cars connect with everything nearby. They send data smoothly using Wi-Fi and cellular systems. This lets cars talk to other cars, roads, and even people. It makes driving safer by avoiding crashes. It also helps traffic move better by guiding cars. With these connectors, driving becomes smarter and safer.

Using IoT and self-driving tech in cars

The Internet of Things (IoT) is changing how cars work. Car makers now use IoT to make driving easier. These systems link car parts to share data and fix problems early. Self-driving cars also need IoT and fast connectors to work well. This mix of tech is now common in new cars. It helps create smarter cars that can drive themselves.

Wireless connectors for better car entertainment

Wireless connectors are improving in-car entertainment systems. They now send data faster for better music and videos. These connectors make car designs simpler and keep data safe. For example, MATE-AX connectors send data super fast, up to 20GHz. They also help with smart driving tools and fun features. This makes every ride smooth and enjoyable.

Eco-Friendly Materials in Vehicle Connectors

Using greener and recyclable materials

The materials in car connectors help protect the environment. Companies now use eco-friendly options like bioplastics and special metals. These materials lower pollution and follow strict green rules. For example, a bio-based plastic used in connectors cuts carbon emissions by 50%. This helps make cars lighter and better for the planet.

Switching from gold to nickel alloy in connectors is a big step. Gold mining creates 800 kg of CO2 per ounce, but nickel alloy makes only 0.2 kg. This change can save 7.8 million kg of CO2 each year. Choosing recyclable materials reduces waste and helps keep Earth clean.

Making connector production less harmful

Old ways of making connectors hurt the environment. They used dangerous materials and wasted energy. Now, companies use safer materials like recyclable metals instead of cadmium. Recycling programs reduce leftover scraps, and energy-saving methods cut pollution. Designing connectors to be reused keeps them out of landfills. These changes make production cleaner and smarter.

New ideas for eco-friendly connectors

New designs are making connectors better for the planet. Special silver materials work well in electric cars and lower pollution. Bioplastics and advanced metals replace older materials, making connectors stronger and greener. These improvements help fight climate change and improve car technology. By using these solutions, we can protect the planet while advancing car design.

Stronger Connectors for Tough Conditions

Materials that handle heat and rust

Tough conditions need materials that resist heat, rust, and damage. Metals like stainless steel, aluminum, and brass are strong and don’t rust easily. Special plastics like PEEK and PTFE resist chemicals, making them great for harsh places. Rubber and silicone seals are flexible and block dirt or water. These materials help connectors work well even in hard situations.

New ideas like nanocrystalline nickel alloy improve durability. This alloy replaces gold, cutting harm to the environment but staying strong. It uses thinner layers and recycled tungsten to make it. Nanostructured silver is twice as hard as regular silver. It resists wear and makes connectors last longer and stay eco-friendly.

Coatings that protect better

Coatings help stop connectors from wearing out or rusting. Zinc or nickel coatings block harmful chemicals. New electroplating methods make connectors resist rust even more. Palladium coatings are tough and last a long time. Extra treatments make the palladium stick better to the base material.

These coatings make connectors last longer and work well in rough places. Using better materials and methods, makers create connectors that stay strong under pressure.

Tests to check reliability

Tests make sure connectors work in extreme conditions. Heat tests check if they handle temperature changes. Vibration tests see if they survive shaking. Rust and moisture tests check for damage from water or chemicals. Electrical tests measure how well they carry power. Repeated-use tests ensure they last a long time.

High IP ratings show connectors are safe from dirt and water. Passing these tests means connectors will work well for a long time. These checks ensure your car’s systems stay reliable, no matter the weather.

The car connector market is changing quickly with new trends. Electric cars are becoming more popular, and fast data sharing is needed. Smaller connectors are also in demand for modern car designs. These changes make cars safer and better for the environment. They also help self-driving systems work well. New improvements will lead to smarter and greener transportation.

FAQ

What are vehicle connectors, and why do they matter?

Vehicle connectors join car parts to share power and data. They help cars work well, supporting safety, entertainment, and electric car features.

How do eco-friendly materials help vehicle connectors?

Eco-friendly materials cut pollution and can be recycled. They make connectors stronger and keep car systems working while protecting nature.

Can small connectors handle new car technology?

Yes, small connectors use smart designs and strong materials. They save space and support features like entertainment and self-driving systems.

See Also

Transforming Vehicle Connectivity With HFM Connector Benefits

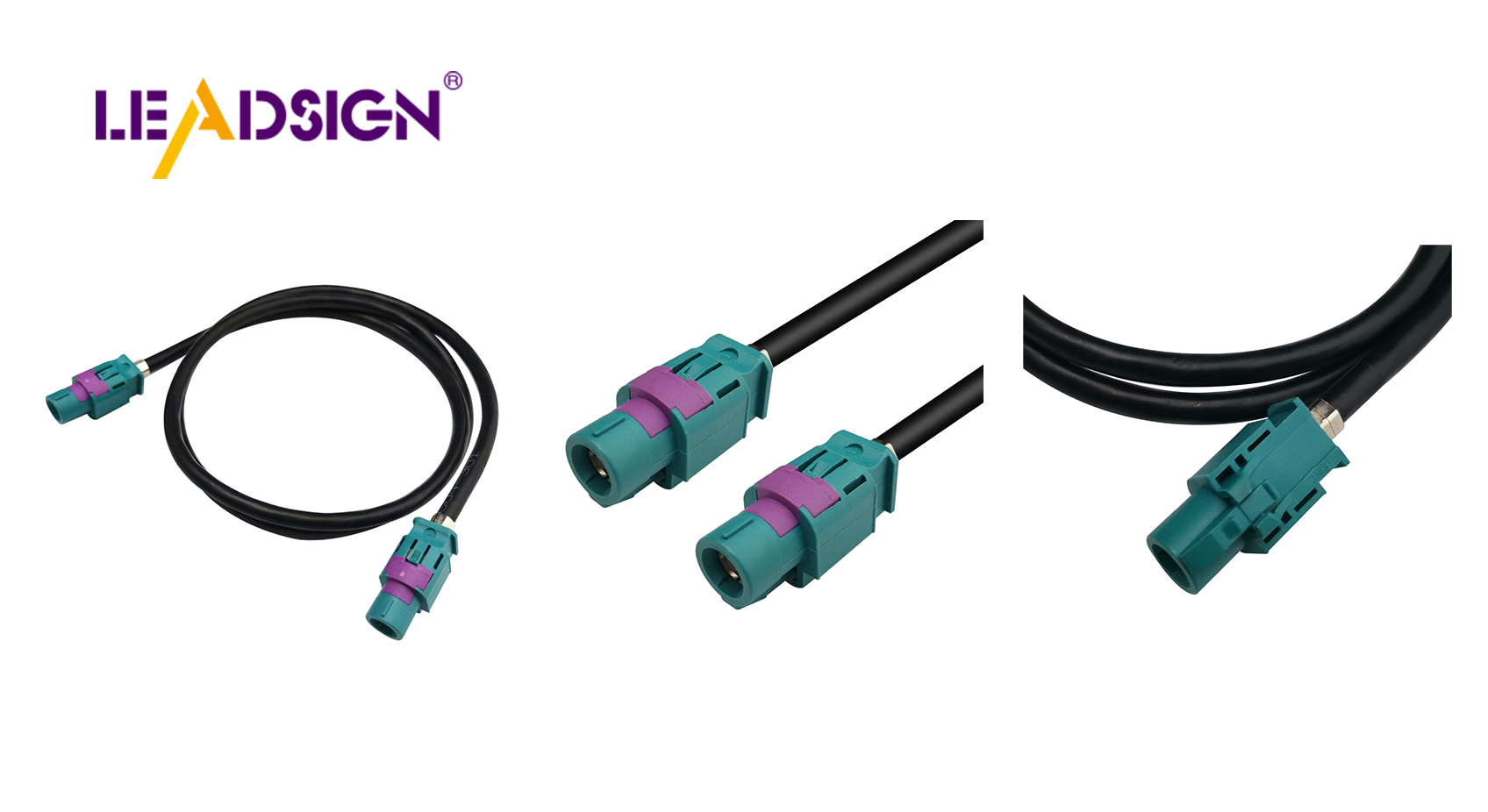

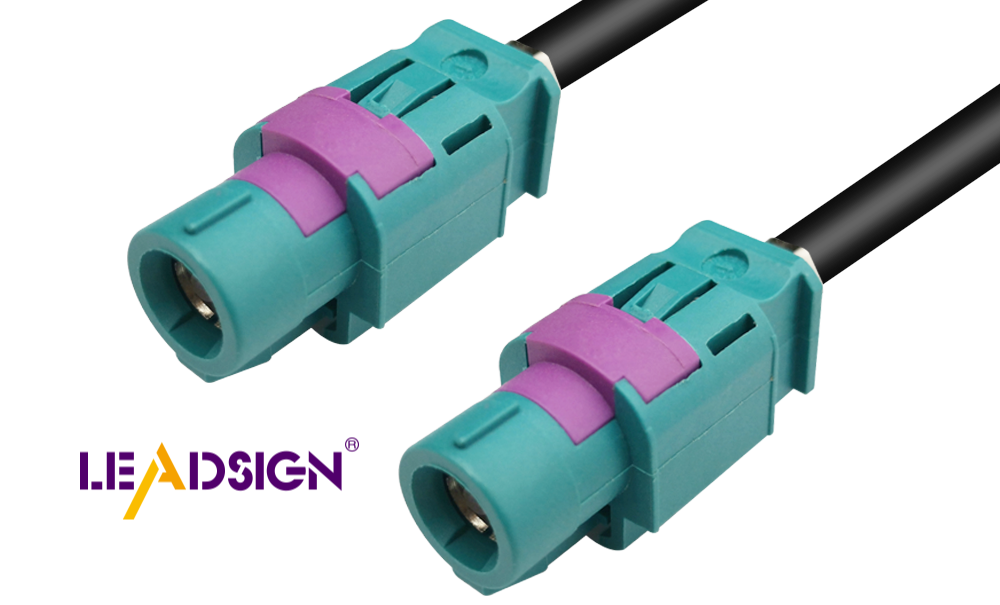

Exploring Mini FAKRA Connectors' Benefits For Today's Cars

Harnessing High-Speed FAKRA-Mini Connectors For Automotive Innovation

Boosting Data Transfer: The Significance of Fast Automotive Connectors