Understanding the Importance of Standards in Types of Wire Connectors Automotive

Automotive electrical connectors types are crucial components in car electrical systems. They play a vital role in facilitating communication and power flow within vehicles. These connectors come in various types to cater to different automotive requirements. Adhering to industry standards, such as USCAR-20, is essential. These standards ensure the safety, reliability, and compatibility of automotive connectors, making them durable in harsh conditions and well-suited for integration with other vehicle components. As automotive technology advances, understanding the different types of automotive electrical connectors becomes increasingly important.

Types of Wire Connectors in Cars

Car electrical connectors are key for smooth power and signal flow. They come in different shapes to fit car needs. Knowing these helps pick the right one.

Common Types

Crimp Connectors

Crimp connectors are popular because they are easy to use and reliable. They work by squeezing a metal piece around the wire for a tight fit. This makes sure the connection is strong and conducts electricity well. The LV214 standard checks crimp strength to find mistakes and keep quality high.

Solder Connectors

Solder connectors make a lasting link by melting solder on the wire and end piece. They conduct electricity well, perfect for steady connections. But, they take more skill and time than crimp ones.

Push-On Connectors

Push-on connectors, or quick-connects, let you connect fast without tools. They're used where you need to unplug often. These give a solid link and are common in car systems.

Special Connectors

Weatherproof Connectors

Weatherproof connectors handle tough weather like rain, dust, or heat changes. They have seals to keep water out, great for outside or under-the-hood use. These help car systems last long.

High-Temperature Connectors

High-temperature connectors work in hot places using materials that don’t melt easily. They’re important in engine areas where it gets really hot.

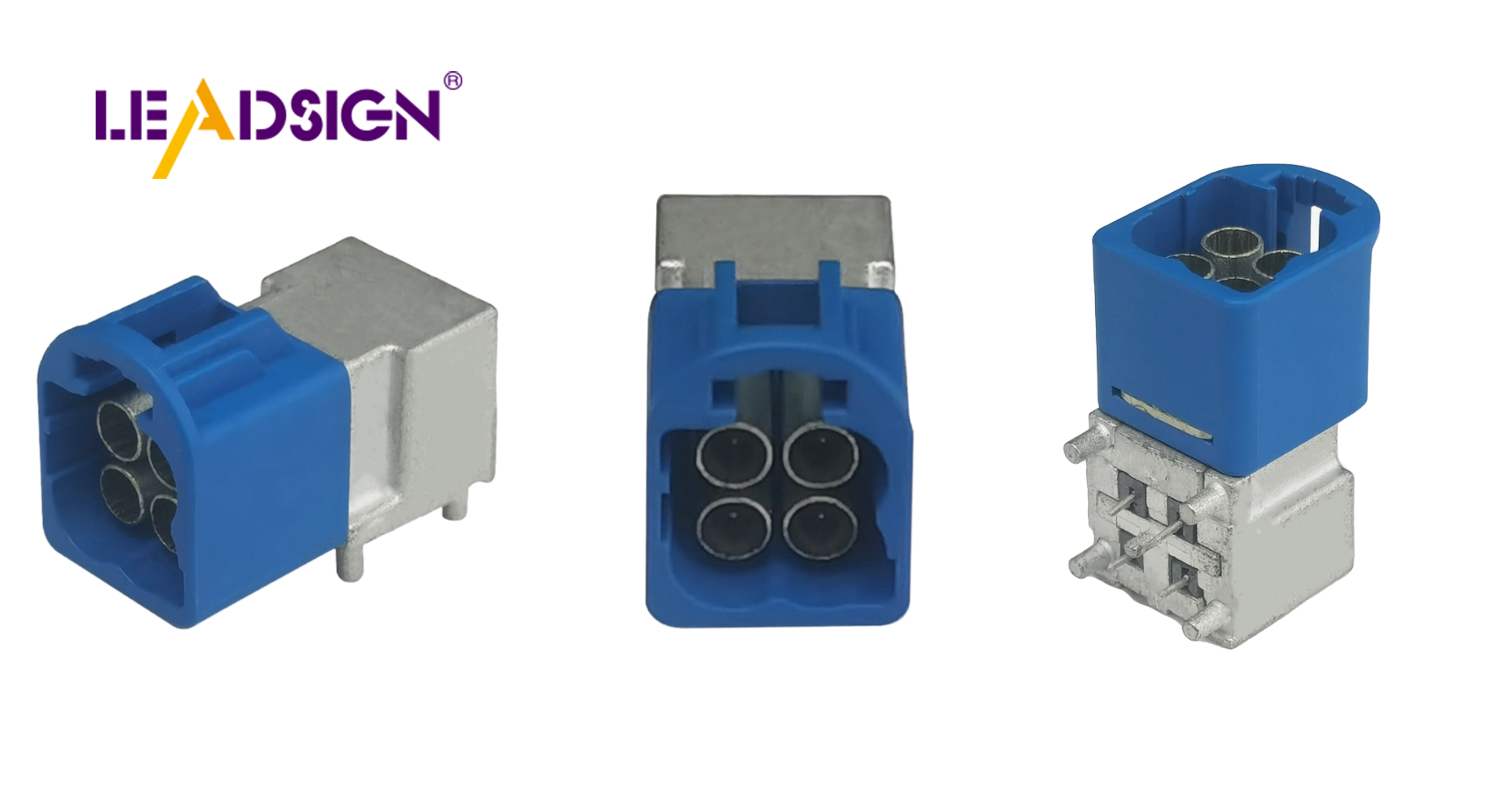

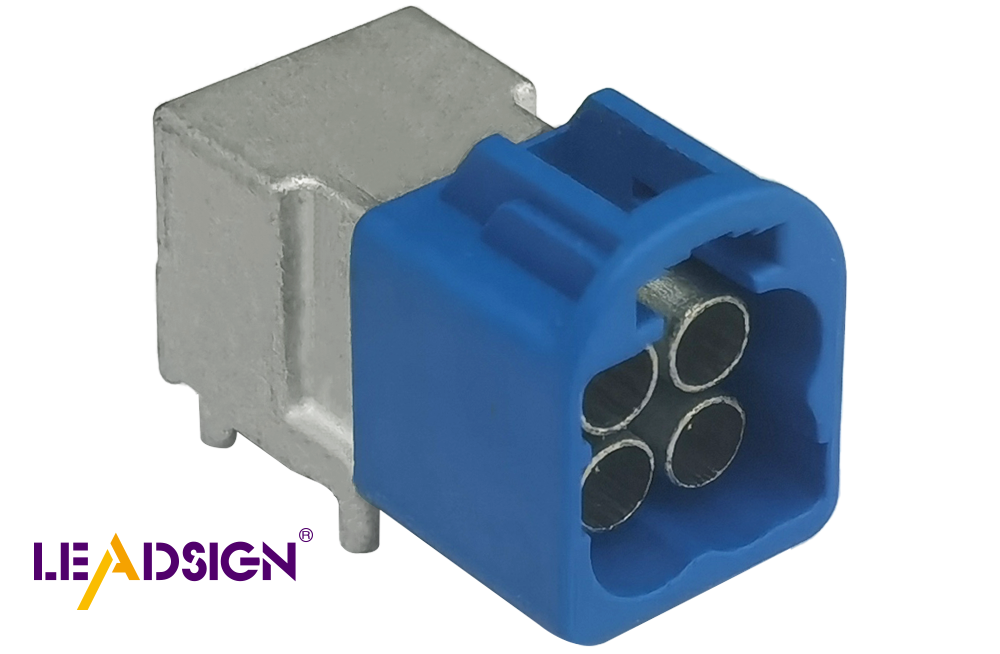

High-Speed Data Connectors

High-speed data connectors like those in HSD Connector setups move data fast in cars. They support things like LVDS, USB, and Ethernet for screens, cameras, etc., inside cars. The Wire Harness organizes these so they meet rules and work well.

Characteristics of Automotive Wire Connectors

Car wire connectors are important for vehicle systems to work well. Their materials and design make them effective and reliable in cars.

Material Composition

The materials used in car wire connectors affect how they work and last.

Conductivity

Conductivity is key for car wire connectors. Materials like copper help power flow easily. They cut energy loss, boosting the car's electrical system. Following rules, makers keep good conductivity for safe driving.

Durability

Durability matters too. Connectors face tough weather, heat, and shakes. Thermoplastics and metals that resist rust are used to make them last long. Industry Standards in Automotive Wire Harness Design stress using strong materials for safety.

Design Features

Design helps car wire connectors fit well and be easy to use.

Size and Shape

Connectors come in sizes to match car parts. Small ones fit tight spots; big ones handle more power. Makers think about the car's setup when designing them.

Compatibility

Compatibility is crucial for connector design. They must work with other parts smoothly. Standards like USCAR guide makers to ensure this, making sure connectors fit into different car systems well.

Importance of Standards in Automotive Wire Connectors

Standards are very important for car connector design. They make sure connectors are safe and work well, which is key for cars.

Safety and Reliability

Stopping Electrical Problems

Car connectors must stop electrical problems to keep cars safe. Rules like USCAR-20 help makers build strong connectors. These rules ensure connectors can handle shakes, heat changes, and wetness. This lowers the chance of electrical issues. By following these rules, makers create reliable connectors that prevent accidents or car troubles.

Keeping Performance Steady

Steady performance is crucial for car connectors. Standards make sure they send power and data reliably in cars. For example, connectors in engines or radios must work well always. By using standards, makers promise their connectors stay strong, helping cars run smoothly and safely.

Compliance and Regulation

Industry rules

Industry rules like UL 4, UL 13, and UL 44 matter a lot for car connectors. These cover things like cable safety to meet specific needs. Following these rules helps make sure connectors fit with other car parts easily, keeping cars working right.

Legal needs

Legal needs also affect making car connectors. Laws say they must be safe to use in cars. Meeting these laws keeps everyone safe and avoids legal trouble for makers.

Standards for car wire connectors are very important. They help keep cars safe and working well. These rules guide makers to build good and strong parts. This makes cars last longer. Following these rules stops problems and keeps cars safe. The car industry uses strict rules and ISO badges to stay safe and good. Makers must follow these rules to stay trusted and do well in business. So, using these standards is key to making better cars and keeping everyone on the road safe.

See Also

The Significance of High-Speed Data Connectors in Automotive

The Value of Fakra Connectors in Automotive Applications

The Role of Fakra Connectors in Contemporary Vehicles