Why OEM Automotive Electrical Connectors Matter

Car electrical connectors, particularly the various automotive electrical connectors types, are very important for safety and reliability. They fit perfectly with certain car models, which lowers the chance of electrical problems. These connectors are made to exact standards, ensuring high quality and good connections. Using these connectors helps car makers avoid expensive electrical issues and damage. The materials in these connectors are strong and last long, giving dependable performance. This makes them crucial for keeping car systems working well.

Benefits of Using OEM Automotive Electrical Connectors

Enhanced Durability

OEM connectors are very strong. They handle tough car conditions like heat, shaking, and wetness. Made from good materials, they last long. This means fewer replacements, saving time and money. With OEM connectors, cars stay reliable over time.

Reduced Risk of Electrical Failures

OEM connectors lower the chance of electrical problems. They fit perfectly with car systems. This stops issues like short circuits or loose wires. These problems can be dangerous or costly to fix. OEM connectors make sure the car's electrical system is safe and works well.

Ensuring Compatibility

OEM connectors match the car's systems exactly. They work well with all electronic parts in the car. This is important for things like power steering and music systems to work right. Using OEM parts avoids problems that other parts might cause. This keeps everything running smoothly and protects the car's warranty.

Types and Uses of OEM Connectors

Car Electrical Connector Types

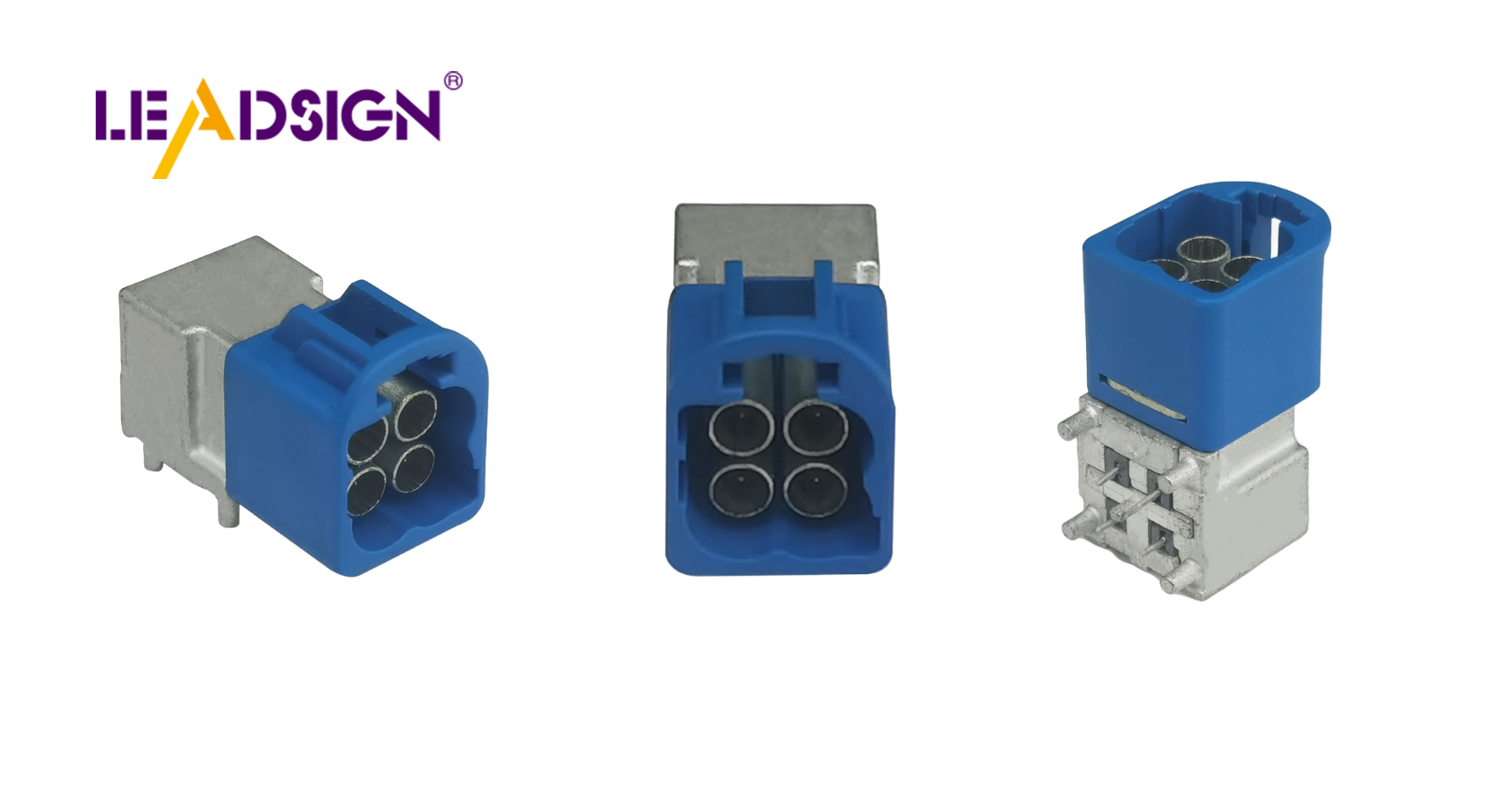

Car electrical connectors have different types. Each type has a special job in cars. OEM automobile connectors are made to fit car makers' exact needs. They are high quality and very reliable. These connectors come in many shapes and sizes, matching the car's brand and model. They can handle tough conditions like heat, water, and shaking. This makes them last long. The materials used are strong and don't wear out easily, giving steady performance over time.

Power Connectors

Power connectors help send electricity to parts inside a car. They manage high power levels well, making sure power spreads right. OEM connectors go through hard tests to work well in cars' tough conditions. They give a safe connection, lowering electrical problems risk. Made with good materials, these connectors last longer and keep things safe. This is why they are key for keeping the car's electric system working well.

Signal Connectors

Signal connectors move data between electronic parts in cars. They help systems like maps, music players, and driver helpers talk to each other smoothly. Wire connectors with OEM specs fit perfectly with OEM gadgets, stopping signal mix-ups or losses. These meet industry rules for good performance and safety checks. Using OEM signal connectors helps car makers keep systems working great and protects the car's warranty.

Specialty Connectors

Specialty connectors are very important in cars. They do special jobs in the car's electric system. OEM automobile connectors often have these special parts for certain uses, making sure they work well and last long.

Custom Design: These connectors are made to fit car makers' needs exactly. They fit perfectly into the car, doing their job well in different conditions.

High-Performance Materials: The stuff used is strong against heat, wetness, and shaking. This makes them last longer and work better.

Specific Applications: Specialty connectors help with new car tech like self-driving and music systems. They make sure power and data move right, keeping everything working.

Rigorous Testing: Like other OEM parts, these go through hard tests to meet rules. This makes sure they can handle what modern cars need safely.

Enhanced Safety: Using these connectors helps stop electrical problems in cars. They give safe connections, lowering risks of shorts or other issues.

Best Practices for Installing OEM Connectors

Proper Handling and Installation Techniques

Handle OEM automotive connectors carefully. This keeps them working well. Always follow the maker's instructions when installing them. Use the right tools to avoid breaking them. Make sure connectors are clean before use. This helps make a good electrical link.

OEM wiring connections are made from strong stuff. They resist heat, water, and shaking. Install them properly to use these strengths. Don't bend or twist connectors too much. This can break them. Doing this keeps the car's electric system reliable.

Regular Maintenance and Inspection

Check OEM automotive connectors often to keep them working well. Car owners should look for damage regularly. Check for rust, loose parts, or breaks. Fixing these fast stops bigger problems.

Wire connectors with OEM rules keep electric links safe. Regular checks help meet safety rules and stop problems like shorts or fires. Keeping these in good shape helps cars run smoothly.

In short, following good steps for using and checking OEM automotive connectors boosts car safety and performance. Careful handling, proper setup, and regular checks are important for getting the most from these key parts.

OEM automotive electrical connectors are very important for car safety and how well they work. They make sure connections are strong and fit right, which is needed for the car's electric parts to work properly. Picking OEM connectors gives many good things, like being tough and lowering the chance of electric problems.

Expert Testimony: "Keeping electricity safe is super important, and wire connectors with OEM help keep these connections safe."

To get the most out of these benefits, it's key to follow best ways to put them in and take care of them. Checking them often and handling them right helps keep everything working well, making cars safe and good on the road.

See Also

Why HSD Connectors Are Crucial for Automotive Success

Fakra Connectors: Essential Components for Today's Vehicles

Fakra Connectors: Key Elements in Automotive Engineering

Understanding the Role of FAKRA Connectors in Cars

Boosting Data Transfer with High-Speed Automotive Connectors