The Critical Importance of OEM Auto Wire Connector Types

Car wire connectors, a key category among automotive electrical connectors types, are very important in cars. They help send power and data smoothly, which is essential for vehicles to function properly. Choosing the right car electrical connectors enhances safety and performance. These connectors are designed to withstand tough conditions, ensuring their longevity. The global demand for these connectors highlights their significance in the automotive industry. Utilizing OEM solutions allows car manufacturers to meet the evolving needs of new vehicles while maintaining high safety standards.

Benefits of Using OEM Automotive Electrical Connectors

Durability

Resistance to environmental factors

OEM connectors are very strong. They handle tough weather like heat, cold, and wetness. These connectors stay good in hard situations, helping cars run well. Their strong build stops them from breaking down, which keeps the car's electric parts working.

Longevity in automotive applications

OEM connectors last a long time in cars. They are made to be durable, so you don't need new ones often. This helps the car's electric system last longer. Using OEM connectors means cars work well for years, saving money on fixes and making owners happy.

Reliability

Consistent performance under various conditions

OEM connectors work well no matter what. They keep electric connections steady, which is important for modern cars to run smoothly. These reliable connectors help important systems like power steering and safety features work right. This makes driving better and keeps cars safe.

Compatibility with automotive systems

OEM connectors fit perfectly with car systems. They are made to match the car's electric setup easily. This fit makes sure everything works together without problems. Choosing OEM connectors means cars run as they should, making drivers feel secure.

Safety

Prevention of electrical failures

Safety is key in car design. OEM connectors stop electric problems from happening. They make tight connections that lower the chance of wires coming loose or shorting out. This is crucial for keeping the car's electric parts safe and sound.

Protection against short circuits and fires

OEM connectors guard against shorts and fires. Their design stops sparks and overheating from happening. This protection keeps both the car and people inside safe. By using these connectors, makers follow strict safety rules, cutting down on accidents caused by electric issues.

Types of OEM Automotive Electrical Connectors

Blade Connectors

Common uses and advantages

Blade connectors are often used in cars. They help parts like lights work well. These connectors are easy to use and save time when putting them in. They carry electricity well and don't rust, so they last long.

Installation considerations

When putting in blade connectors, make sure they fit tight. This stops them from coming loose. Pick the right size for the car's needs. Check them often to see if they wear out.

Pin Connectors

Applications in modern vehicles

Pin connectors are important in new cars. They connect parts like engines and safety systems together. This helps the car work safely and smoothly.

Benefits over other types

Pin connectors are small but strong. They stay connected even if the car shakes or bumps around. They send signals well, which is key for high-tech car parts.

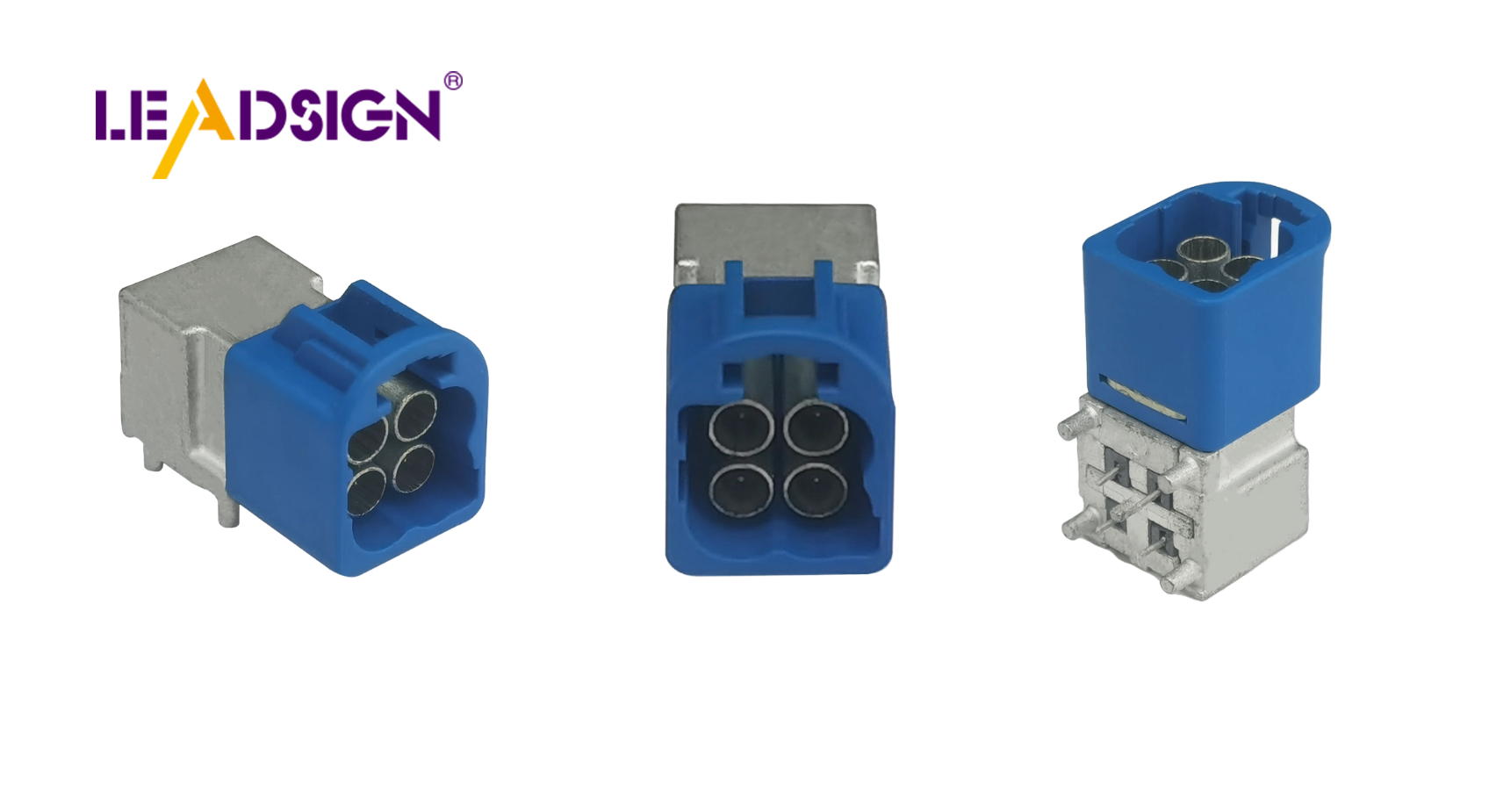

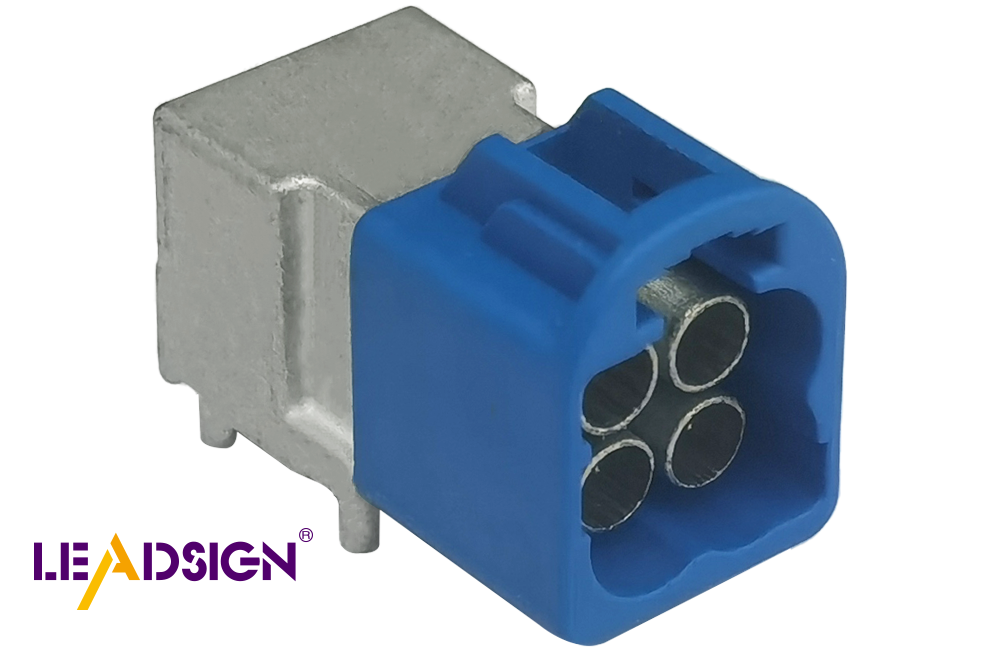

High-Speed FAKRA-Mini Connectors

Description and uses

High-Speed FAKRA-Mini connectors are new and fast. They send lots of data quickly, good for things like GPS and self-driving tech.

Advantages and limitations

These small connectors save space inside cars. They fit into many systems easily but need careful handling to work best.

Uses of OEM Connectors in Different Fields

Car Industry

Part in making cars

OEM connectors are key in making cars. They help all electric parts work well. Makers use them to keep quality and safety high. The big need for these connectors shows their worth. Using OEM connectors means cars meet tough rules. This makes sure they run well and safe.

Value in fixing cars

In fixing cars, OEM connectors are important. They give good solutions for repairs and upgrades. Fixers like them because they fit right with car systems. This lowers the chance of electric problems. Using them keeps cars working like new, making owners happy.

Gadget Industry

Uses in gadgets people buy

OEM connectors are used a lot in gadgets. They link parts in things like phones and laptops. These connectors make gadgets work better and last longer. By using them, makers can make products more reliable, which users like.

Benefits like better connections

Gadget makers gain from OEM connectors by getting better links. These help send data fast, needed for new devices. They also last long and handle bad weather well. This makes them great for many gadget uses. With these connectors, makers can boost product quality and stay ahead.

Best Ways to Install OEM Automotive Electrical Connectors

Choosing the Right One

Picking connectors for what you need

It's important to pick the right OEM car electrical connectors. Technicians should check what each job needs. Think about how much power is needed and where it will be used. Also, see if there's enough space. By choosing the right ones, connections work well and stay strong.

Making sure they fit with car systems

Connectors must fit with car systems. OEM connectors are made to fit perfectly in cars. This stops problems and makes sure everything works together smoothly. Technicians should check that connectors match the car's needs to keep things working right.

How to Put Them In

Steps for safe connections

To make safe connections, follow these steps:

Get wires ready: Carefully take off the cover without hurting the wire.

Pick the right connector: Make sure it fits the wire size and job.

Crimp or solder it: Use proper tools to join wire and connector strongly.

Check it over: Look for loose wires or bad crimps that might cause issues.

Seal it up: Use heat shrink or tape to keep out water and dirt.

Avoiding mistakes when installing

Avoiding mistakes is key for good connector work. Don't tighten too much as it can break parts. Don't use wrong tools that might bend connectors badly. Training and following rules help stop these errors.

Keeping Them in Good Shape

Regular checks for damage

Checking connectors often keeps them lasting long. Look for rust or broken parts regularly. Using special grease stops rust from building up on terminals, keeping them working well.

Tips to make them last longer

To make connectors last longer:

Keep them clean: Remove dirt that can scratch or rust them.

Use protective sprays: Spray anti-rust stuff on them for protection.

Store properly: Keep in dry places so they don't get ruined.

By doing these things, technicians ensure OEM car electrical connectors work well, keeping cars safe and efficient.

OEM connectors are very important for car safety and work well. They help power and data move smoothly, which keeps cars reliable. As more cars need strong parts, OEM connectors keep getting better. Future changes will make them last longer and work better.

To fix connector problems, check them often for damage. Make sure they are put in right. Learning about connectors is important too. This helps workers know the newest ways to use them, keeping car tech top-notch.

See Also

Why Fakra Connectors Matter in Today's Automotive Sector

The Significance of HSD Connectors for Cars Today

Fakra Connectors: Essential Components for Modern Vehicles