Why Material Matters in Automotive Wire Connectors

Automotive wire connectors are crucial in vehicles, ensuring smooth electrical flow. The material used significantly impacts their performance and safety. High-quality materials enhance the longevity and efficiency of car components, contributing to overall vehicle safety and efficiency. There are various automotive wire connectors types, such as crimp, solder, and push-on, each requiring specific materials to function properly. Understanding the importance of material selection is key to ensuring safe and effective vehicle performance.

Understanding Automotive Wire Connectors

Function and Role in Vehicles

Automotive wire connectors are very important for cars. They help electricity move easily between parts. This smooth flow is needed for everything to work well in a car.

Electrical Connectivity

Wire connectors keep electrical links strong and steady. They join wires tightly, so power flows without stopping. This is especially important when lots of electricity is needed.

Signal Transmission

Besides power, wire connectors also send signals. They help different car parts talk to each other, like sensors and computers. This makes sure the car works right and listens to the driver.

Automotive Wire Connectors Types

There are different types of automotive wire connectors for different jobs in cars. Each type has special uses that make it good for certain tasks.

Crimp Connectors

Crimp connectors are popular because they work well and are easy to use. You squeeze a metal piece around the wire to hold it tight. This way, they conduct electricity well and don't shake loose.

Solder Connectors

Solder connectors make a lasting link by melting solder on the wire joint. This makes them strong and perfect for reliable connections. Soldering keeps resistance low and helps electricity flow well.

Push-On Connectors

Push-on connectors let you connect or disconnect quickly. They're great when you need to unplug often. These fit snugly and work where space is small.

Product Information:

Wire Connectors: Important for electric systems, with high conductivity.

Wire Terminals: Make things last longer with special coatings.

Scotch Locks: Fix things fast without taking apart or soldering.

Material Choice for Wire Connectors

Common Materials Used

Picking the right stuff for car wire connectors is key. Different materials give special benefits that make connectors work better and last longer.

Copper

Copper is a top pick for wire connectors. It lets electricity flow well, making power move easily. Copper doesn't rust, so it's good for long use in cars. It's also bendy, which helps during setup.

Aluminum

Aluminum is a lighter choice than copper. It still lets electricity pass while costing less. Aluminum doesn't rust much, which is great where it gets wet often. This material makes cars lighter, helping save fuel.

Brass

Brass mixes copper and zinc's perks, giving high conductivity and strength. It fights rust well, fit for tough car places. Brass connectors are used where strength and trust are needed.

Factors Affecting Material Choice

Choosing the right material needs thinking about some main things. These ensure connectors work well and safely in different conditions.

Conductivity

Conductivity matters for wire connector efficiency. Materials like copper and aluminum shine here, letting electricity flow smoothly. High conductivity cuts energy loss and keeps car systems working right.

Corrosion Resistance

Corrosion resistance keeps wire connectors strong over time. Wetness and other factors can cause wear out. Materials like copper, aluminum, and brass resist rust well, ensuring they last long.

Mechanical Strength

Mechanical strength shows how tough wire connectors are under stress. Strong materials stop damage from shakes and hits common in cars. Tough copper alloys and brass give needed strength to handle these tests.

How Material Affects Performance and Safety

Performance Points

Electrical Power

The material in car wire connectors affects power flow. Copper helps electricity move well because it conducts power easily. This means less energy is lost, making car parts work better. Aluminum is lighter but still lets power flow well, saving money.

Heat Holding

Heat holding is key for connector work. Brass and copper alloys handle heat without breaking. They stop overheating, keeping connectors steady in different situations. This protects the car's electric parts.

Safety Effects

Fire Risks

Picking the right material cuts fire risks. Materials like copper and aluminum don't rust easily, lowering chances of electric problems. This protection stops fires, keeping people safe.

Strength and Lasting

Strength and lasting are important for safety. Tough materials like brass stay strong against shakes and hits. This toughness keeps connectors working over time, helping cars stay reliable longer.

Future Trends in Material Innovation

New Materials

Mixed Materials

Mixed materials are getting popular in car making. They mix two or more things to make something stronger and lighter. These are great for cars because they help them use less fuel and work better. Mixed materials last long, so car parts don't need changing often.

Tiny Tech Uses

Tiny tech is changing how we make stuff. It works with very small pieces to make things better. In car wire connectors, tiny tech can make them conduct electricity well and not rust. This makes connectors work better and last longer. As tiny tech grows, it will bring new ideas for car materials.

Green Ideas

Earth-Friendly

Being earth-friendly matters more now in making cars. Car makers want to use stuff that doesn't hurt the planet much. Green materials help cut down on pollution from cars. By picking these for wire connectors, the car world can help keep the planet clean.

Reuse and Trash

Reusing and trashing car stuff is key for saving nature. The stuff used in wire connectors decides how easy they are to recycle. Easy-to-recycle materials cut waste and save resources. Good trash methods stop bad stuff from hurting nature. As green ways grow, reusing and trashing will stay important when picking materials.

Choosing the right material for car wire connectors is important. It helps them work well, be easy to install, and last long. Car makers need these choices to keep cars safe and working well. As technology grows, new materials will appear. These changes promise better efficiency and being eco-friendly. Research and learning in this area are key. They help us improve and face future problems. By knowing more, people can make car systems safer and better.

See Also

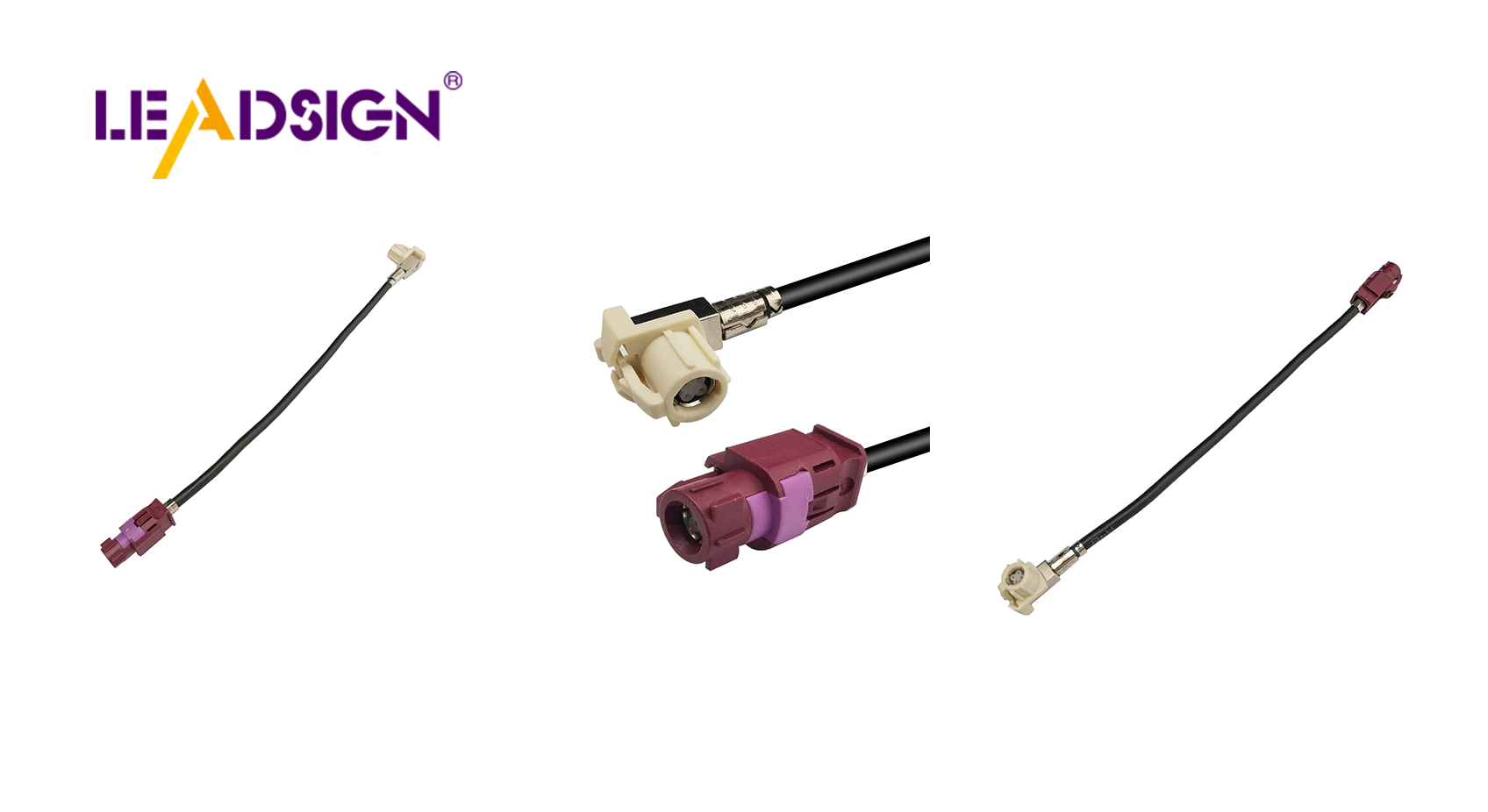

Significance of Fakra Connectors in the Auto Sector

The Significance of Fakra Connectors in Contemporary Cars

The Vital Role of FAKRA Connectors in Auto Uses