Why Automotive Electrical Connectors Types Matter

Automotive electrical connectors types play a crucial role in modern cars. They facilitate communication between different components of the vehicle. With up to 700 connectors and over 3,000 wires in a single car, the significance of these connectors is evident. The increasing number of connectors is a result of the growing complexity of electronic components and safety features in vehicles. The transition from traditional copper cables to advanced plastic fiber cables has significantly enhanced the performance and speed of cars.

Understanding Automotive Electrical Connectors Types

Automotive electrical connectors types are key parts in cars today. They help different systems talk to each other easily. These connectors come in many shapes, each with its own job. Knowing about these types helps pick the right one for a car's needs.

Common Connector Types

Blade Connectors

Blade connectors are very popular in cars. They have a flat piece that fits into a slot. This makes them easy to plug and unplug, perfect for when you need to disconnect often. You can find blade connectors in fuse boxes and relay panels, where they keep circuits connected well.

Pin Connectors

Pin connectors are also common. They have pins that go into matching holes. These can handle many connections at once, so they're good for complex wiring. Pin connectors are used in control units and modules to move signals and power between parts.

Specialized Connector Types

Coaxial Connectors

Coaxial connectors are special for sending high-frequency signals. They have a center wire with layers around it to stop signal loss and interference. This makes them great for radios and GPS systems, working well even in tough conditions.

Fiber Optic Connectors

Fiber optic connectors use light to send data fast without losing quality. They're used more now in advanced driver-assistance systems (ADAS) and infotainment systems because they move lots of data quickly, which is important for modern cars.

Product Information:

Rectangular Connectors: Good for big connections because of their shape; found in control units.

Bullet Connectors: Have a round shape; easy to disconnect; used in simple circuits.

Round Connectors: Best for outside lights; protect from weather; allow turning.

Automotive electrical connectors types make sure car systems work well and safely. By learning about these types, people who work on cars can choose better options, making cars run better and safer.

Rules and Guidelines

Car connectors must follow strict rules to be safe. These rules help make sure connectors work well in cars. Knowing these rules helps pick the right connectors for cars.

Safety Rules

Safety rules are very important for making car connectors. They make sure connectors can handle tough car conditions.

ISO Rules

The International Organization for Standardization (ISO) makes global rules for car connectors. ISO rules ensure connectors can deal with heat and wetness. They also focus on how well electricity flows through them. By following ISO, makers can create safe and good connectors.

SAE Rules

The Society of Automotive Engineers (SAE) has more specific car connector rules. SAE checks if connectors can handle shaking and bumps. These rules make sure they stay connected tightly. By using SAE, makers improve connector strength and trustworthiness.

Fit and Trust

Fit and trust are key when choosing car connectors. Rules here ensure different brands work together easily.

Working Together Rules

Working together rules make sure different brand connectors fit without problems. These help put parts together smoothly in a car, making fixing easier too. By following these, makers ensure their parts fit many systems.

Testing Steps

Testing steps check how well car connectors perform under stress. Tests include heat, water, dirt, and shaking challenges. By doing these tests, makers promise their parts are strong and reliable.

Challenges and Innovations

The world of automotive electrical connectors types is always changing. This brings both problems and chances to invent new things. As cars get more tech, we need better connectors. This part looks at design problems makers face and the smart fixes they find.

Design Challenges

Miniaturization

Making things smaller is a big problem in car making. Cars have more gadgets now, so we need tiny, light connectors. Makers try to shrink wires for more data use. The MultiCat Connector shows this with its small size and light build, fitting tight spaces in engines. It works well even in hot places up to 150˚C.

Environmental Resistance

Automotive electrical connectors types must handle tough conditions like heat, water, and shaking. To last long, makers think about power needs and strong builds. Connectors must stay strong in different weather by using good designs and materials.

Innovations in Connector Design

Smart Connectors

New ideas have made smart connectors that use cool tech to help car parts talk better. These can check their own health and tell us how they're doing right away. This helps fix things faster and stops sudden breakdowns.

Advanced Materials

Using new advanced materials has changed how automotive electrical connectors types are made. Now they use stuff that's strong, conducts electricity well, and fights bad weather. These materials make sure connectors last long while being light but tough for today's cars.

In short, the challenges and new ideas in automotive electrical connectors types show how hard the industry works to make cars better and safer. By solving design issues and trying out new tech, makers keep improving car connections.

Picking the right car connectors is very important. They help keep cars safe and working well. Connectors move electricity and signals in cars. They affect things like music systems and engines. Using the right connector makes cars work better and safer. As more sensors and safety tools are used, connectors matter even more. People should think about which connectors to use when buying or fixing cars. This helps make sure everything works safely and properly in their vehicles.

See Also

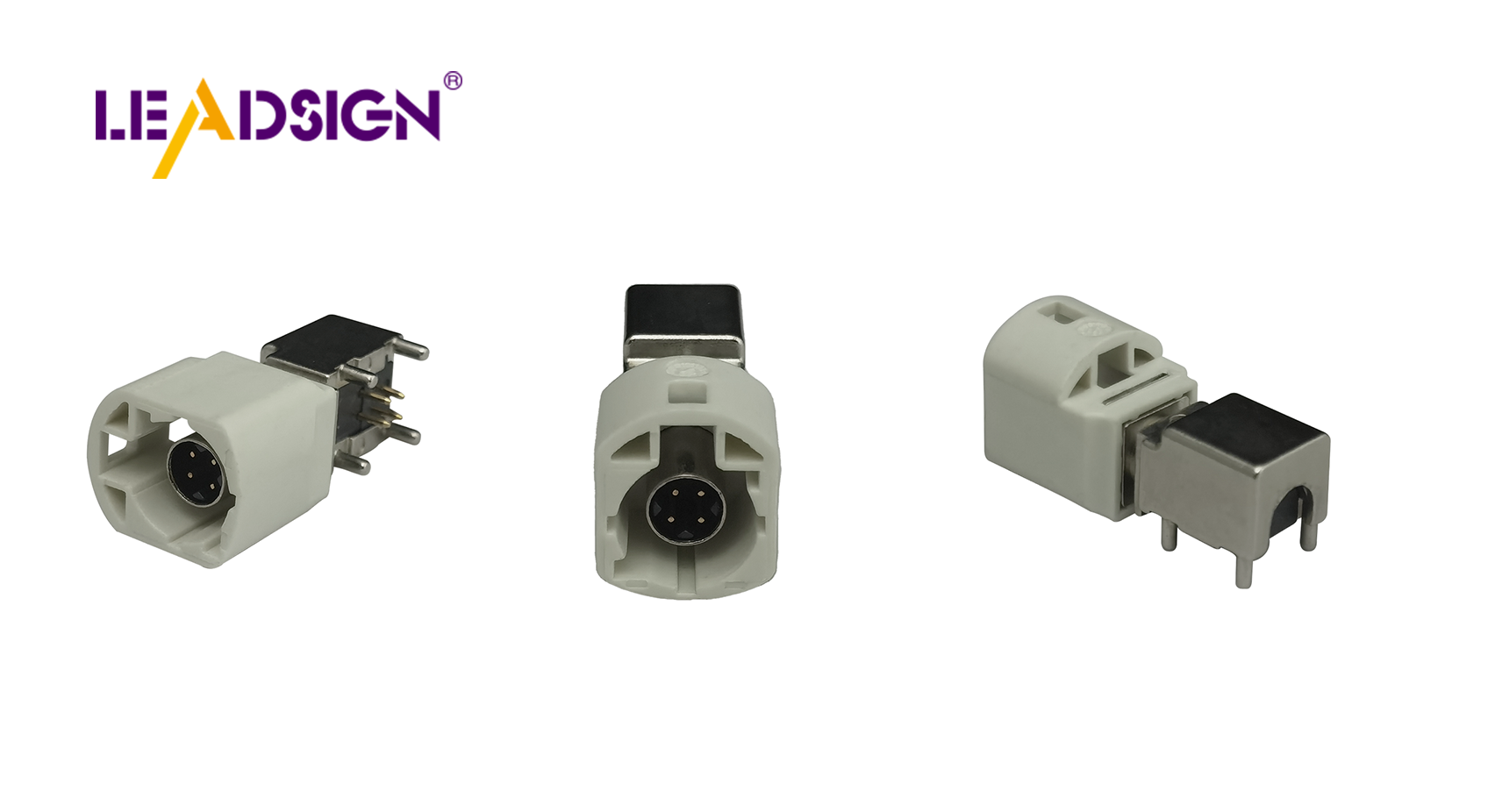

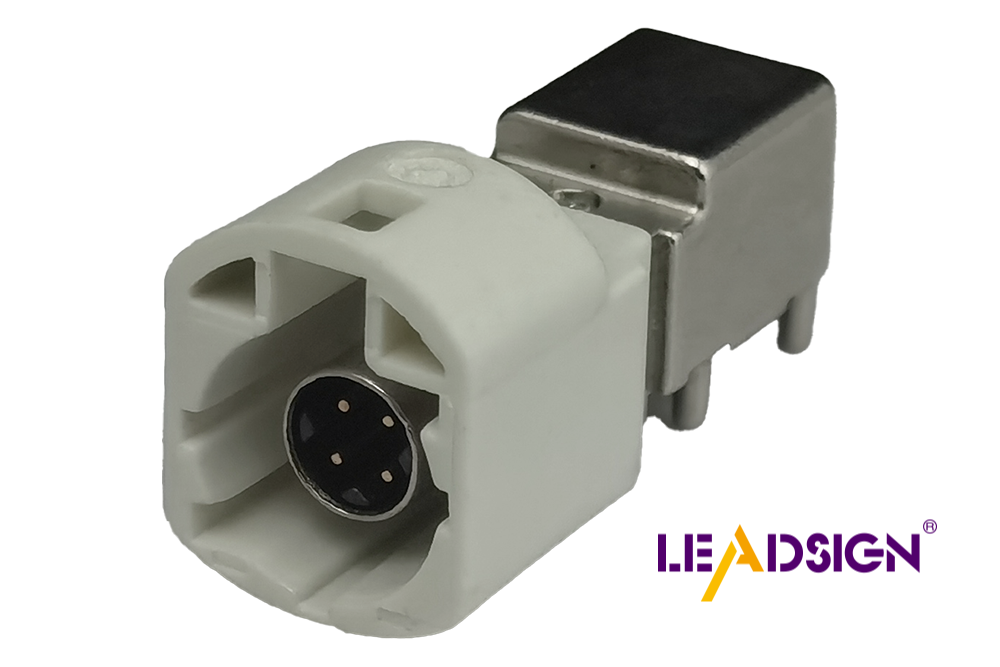

Significance of Fakra Auto Connectors in Contemporary Cars

The Significance of Fakra Connectors in Auto Sector

The Value of HSD Connectors in Auto Sector