Why Automotive Electrical Connectors Types Matter

Automotive electrical connectors types are crucial components in modern vehicles. They play a vital role in ensuring seamless connections between various car parts. With the increasing number of gadgets and technology in cars, the demand for advanced connectors is on the rise. These connectors adhere to standards like USCAR-20 to maintain long-term reliability. While they have a durable lifespan, they will eventually require replacement due to wear and tear. The type of connectors used significantly impacts the performance and safety of the vehicle by facilitating the smooth operation of all electrical components.

Understanding Automotive Electrical Connectors Types

Car electrical connectors are very important. They help different car parts work together well. These connectors handle lots of data and tough conditions. Knowing about them is key for car designers and repairers.

Power Connectors

Power connectors spread electricity in a car. They link the battery to parts, giving power to each one. These need to handle strong currents and heat or shaking. They have locks to stop them from coming loose, keeping power steady.

Signal Connectors

Signal connectors keep signals steady and clear. They join sensors and control units, sending low-power signals that manage car tasks. These need good contact to keep signals right, even when it's tough. Their design stops signal mix-ups.

Data Connectors

Data connectors help parts talk fast in a car. They connect control units, sensors, and actuators for quick info sharing needed for cool features. These must stand up to heat and shaking too. Shielding stops interference with data flow.

Specific Roles and Functionalities

Each connector type has special jobs in a car. Knowing these helps pick the right one for each use.

Role in Power Distribution

Power connectors send electricity around the car. They link the battery to systems so all get power they need. Design handles strong currents and tough spots like heat or shaking.

Role in Data Transmission

Data connectors let parts share info quickly in cars. This helps with advanced features by connecting control units, sensors, and actuators under harsh conditions like high temps or vibrations.

Role in Signal Integrity

Signal connectors make sure signals stay clear and stable between sensors and controls managing functions by stopping interference.

Mechanical Properties and Applications

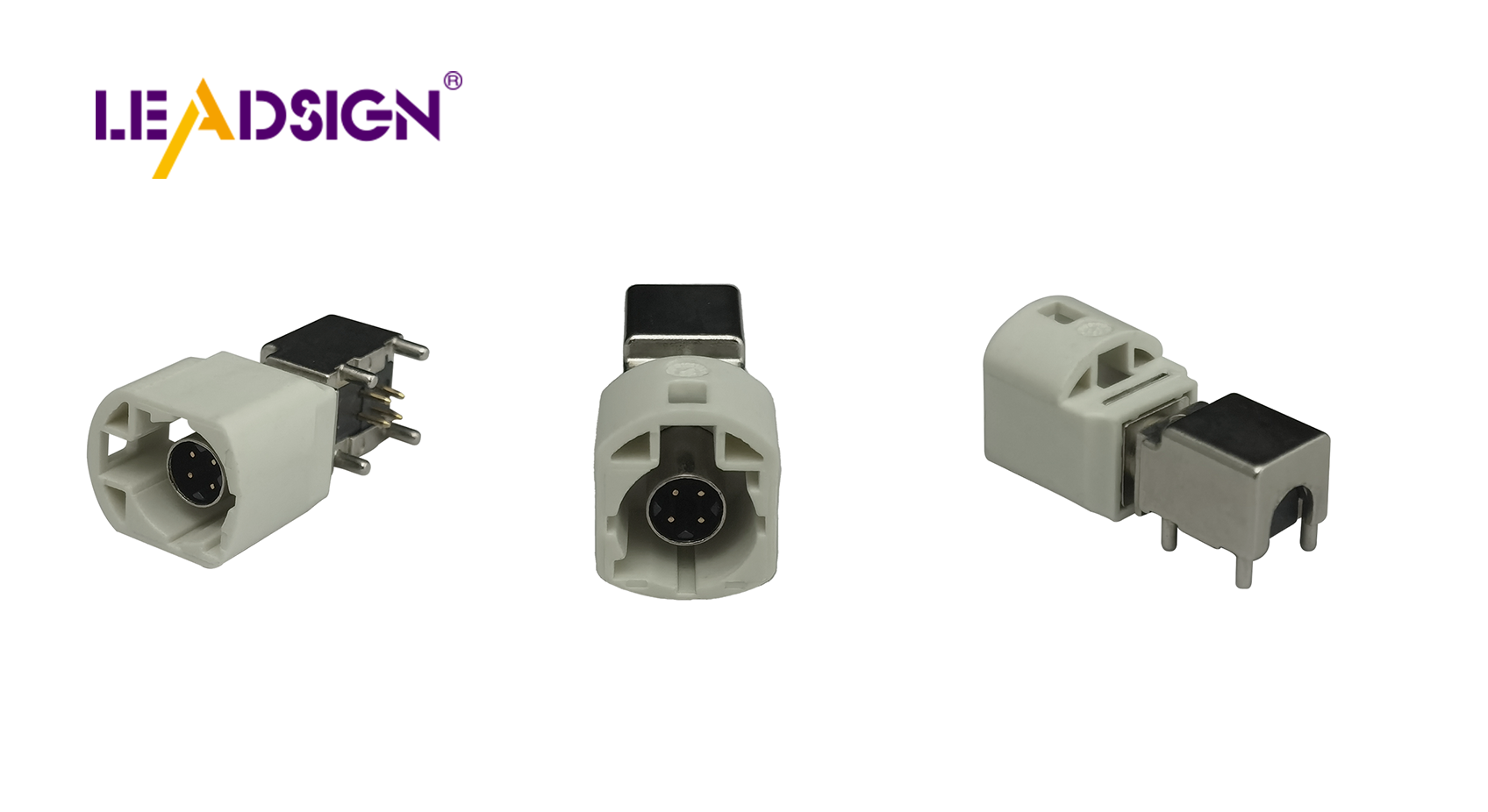

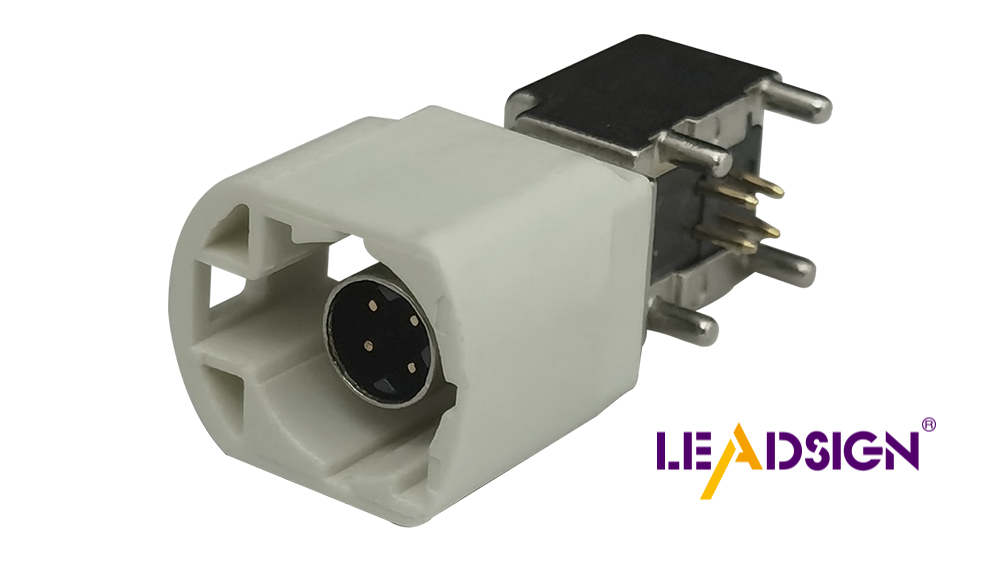

HSD Connector

Importance in Fast Data Transfer

The HSD connector is special for car data transfer. It helps send lots of data quickly in cars. This is important for things like cameras and USBs. The design keeps data moving fast without problems. It has locks and strong cables to stay connected even when it's tough.

Uses in Car Electronics

HSD connectors are used a lot in car electronics. They help with fast data sharing in systems like infotainment. They work with different USB types, making them useful for many devices. They are also used outside cars, like in radio stations. Their strong design makes them good for tough conditions.

Other Connector Types

Strong Build

Other car connectors are very strong too. They are made to handle hot temperatures and shaking in cars. This strength keeps them connected well, which is important for safety systems like airbags.

Weather Protection

These connectors also resist bad weather well. They have seals that keep water and dust out. This protection helps them last long, so car parts work well over time.

Factors That Affect Choosing Connectors

Picking the right car connectors is very important. It helps cars work well and stay safe. Many things affect this choice, and each one matters for how the car's electric parts work.

Reliability

Why It Matters for Car Performance

Reliability is key when choosing car connectors. They must work well in all conditions to keep the car running smoothly. For example, high-voltage connectors need to send signals without problems. How many times a connector can be used before breaking shows its reliability. Makers test them by checking contact resistance during use to ensure they work well.

How It Affects Safety

Safety is super important in cars, and connectors play a big part in it. They need to stay connected firmly to stop electrical problems that might cause accidents. In systems like airbags, reliable connectors mean quick and correct actions. So, picking reliable ones keeps cars safe.

Durability

What Materials Matter

The strength of car connectors depends on what they're made of. They should handle tough conditions like heat and shaking. Newer ones use materials that block interference and insulate well, keeping them working even in hard times.

Lasting Through Tough Times

Car connectors should last long in bad conditions without failing. This means handling temperature changes and stress from movement or rust-causing stuff. Strong connectors help parts last longer, needing fewer fixes or swaps.

Compatibility

Matching Electrical Needs

Connectors must fit the electric needs of what they connect to work right together. This means looking at voltage, current capacity, and signal clarity to avoid issues like lost signals.

Fitting Right Physically

Physical fit means connectors must match the space they go into in a car. They should fit size-wise with proper locks for easy fixing later on.

In short, picking car connectors needs careful thought about reliability, durability, and compatibility so cars perform better and stay safer.

Choosing the right car connectors is very important. They help cars work well and stay safe. Each type has a special job, like sending power, data, or signals. The connectors you pick affect how well these jobs are done. Car connectors must meet strict rules like USCAR-20 for strong design and materials. This helps them last in tough conditions and keep connections steady. Knowing why different car connectors matter helps makers make cars safer and more reliable.

See Also

Significance of Fakra Auto Connectors in Contemporary Cars

The Significance of Fakra Connectors in Auto Sector

The Value of HSD Connectors in Auto Sector