Why Do Automotive Electrical Connectors Types Matter?

Automotive electrical connectors types are crucial for the proper functioning of vehicles. They play a vital role in ensuring that components are securely connected, enhancing the performance and safety of cars. These connectors are designed to withstand challenging conditions such as high temperatures and vibrations. The manufacturing process significantly impacts their durability and functionality. Understanding the various automotive electrical connector types enables manufacturers to select the most suitable ones for specific tasks. This ensures optimal performance and compliance with industry standards.

Understanding Automotive Electrical Connectors Types

Automotive electrical connectors types are key for cars to work well. They help electric systems run smoothly, even in tough spots. Knowing their types and how they work is important for makers and engineers.

Categorization by Performance Standards

T2 to T5 Temperature Ratings

These connectors are sorted by how well they handle heat. The T2 to T5 ratings show the temperatures they can take.

T2 Standard: Good for passenger parts, works from -40 to 100℃.

T3 Standard: Best for engine parts, handles -40 to 125℃.

T4 Standard: Made for hot engine areas, works from -40 to 150℃.

T5 Standard: Fits many uses, takes heat from -40 to 175℃.

These ratings make sure connectors fit different car parts' needs, boosting trust and workability.

Relevance to Specific Automotive Applications

Each rating matches certain car uses. For example, T2 is used where it's not too hot inside the car. But T5 is used near engines where it gets very hot, keeping systems steady and working well. This helps makers pick the right connector for each job, making cars run better.

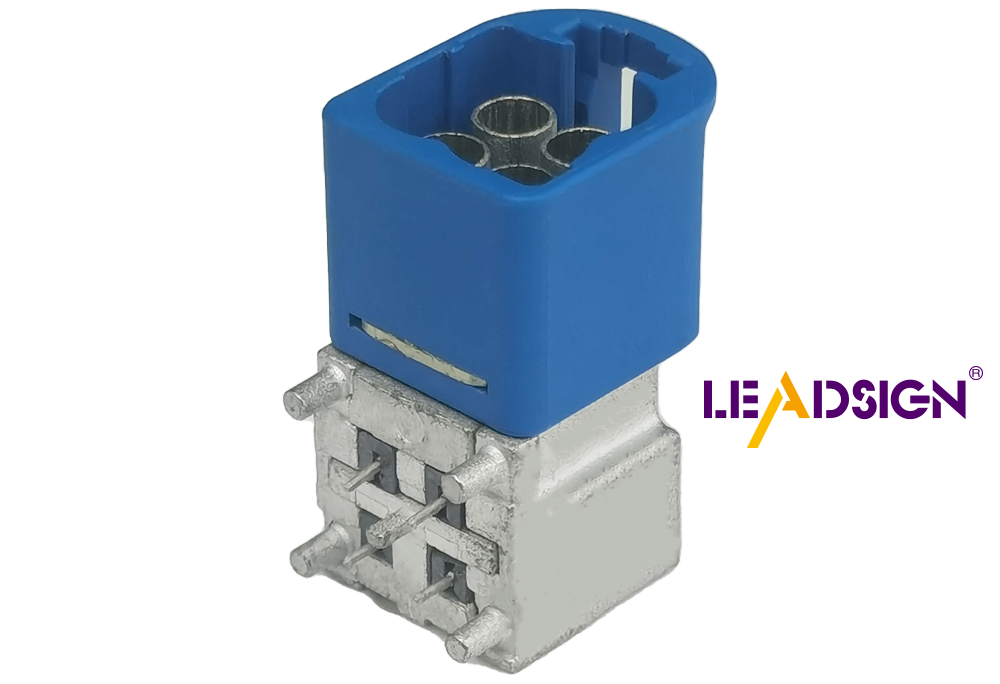

Mechanical Properties of Connectors

Durability and Reliability Factors

The strength and trust of these connectors depend on some features. They must handle shakes, wetness, and other things around them. Things like locks and strong cable grips keep them tough. These features ensure a good connection so the car's electric system doesn't fail.

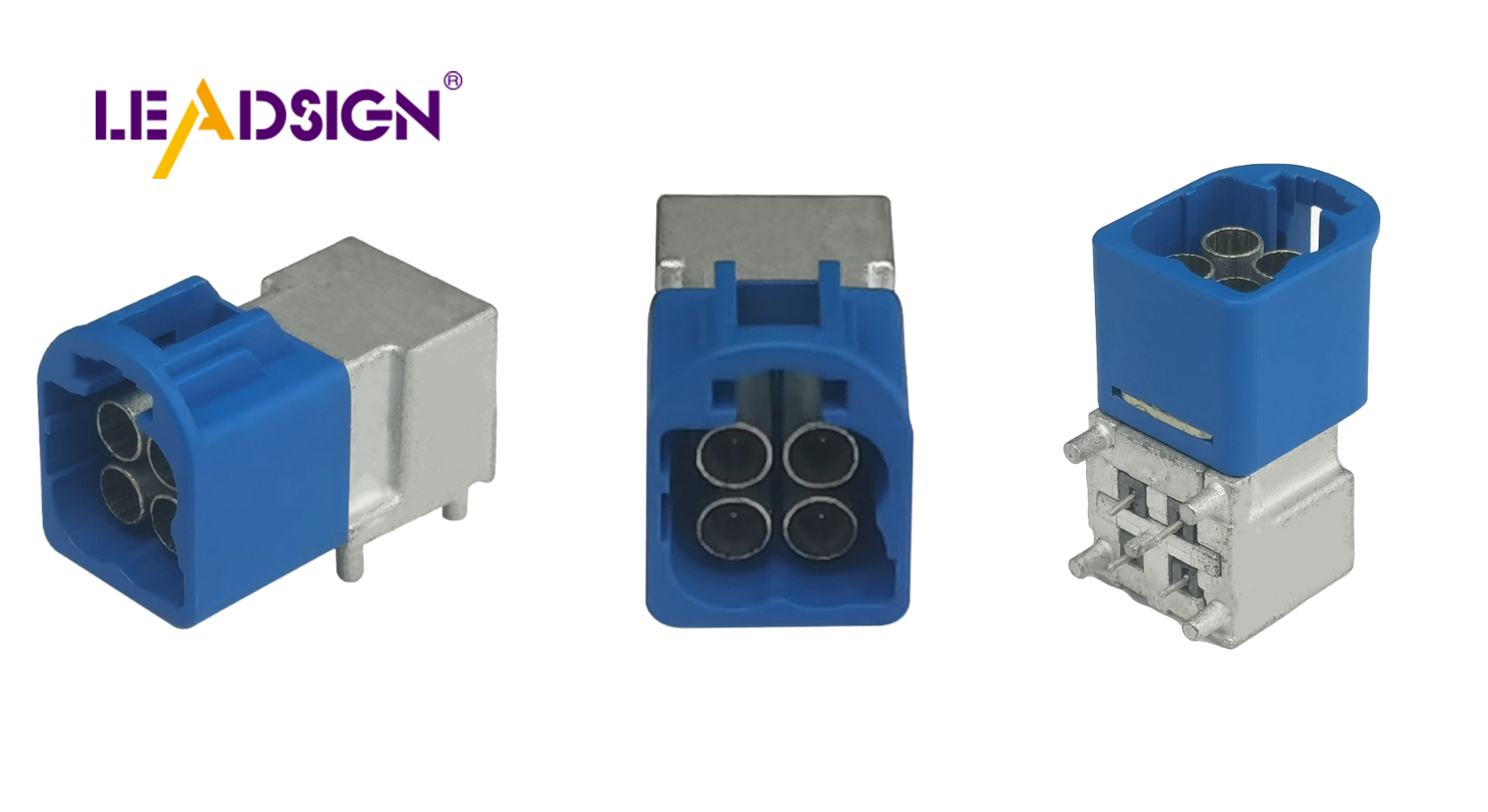

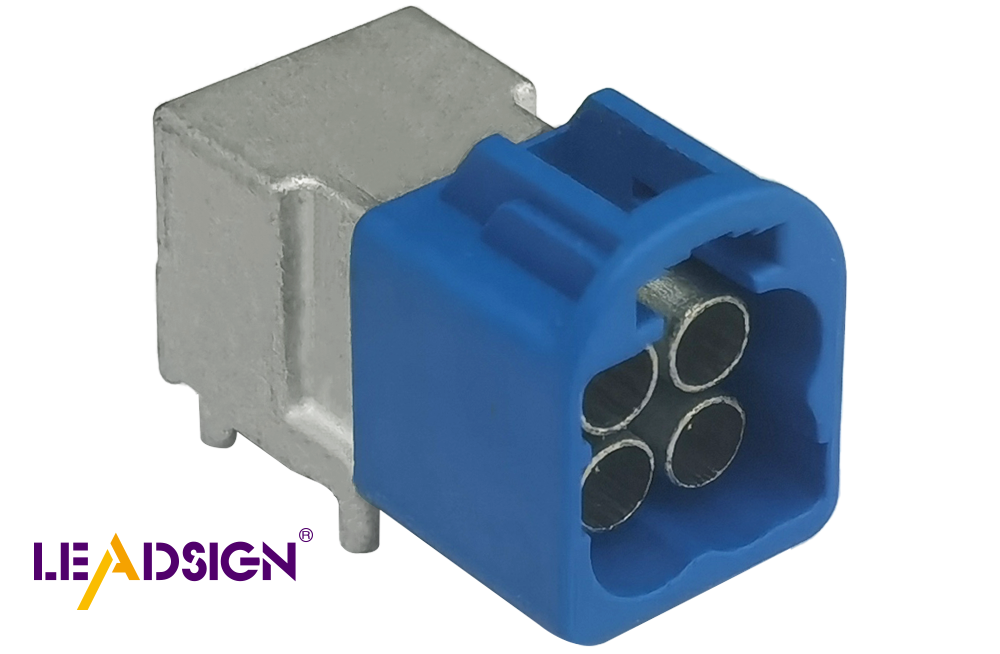

Material Composition and Design

What they're made of and how they're built affects how they work a lot. Makers use stuff that doesn't rust or wear out fast so they last long. Designs stop wrong connections with smart coding. For instance, IPEX Connectors and RF Connectors are made carefully for special needs in industries. These designs make them work better in cars where they're really needed.

Technical Aspects of Connectors

Car connectors are very important. They help cars work well. They let power and data move between parts. Knowing how they work helps makers choose wisely.

HSD Connector

Role in Fast Data Transfer

The HSD connector is special. It moves data fast. It works with things like cameras and USBs in cars. This makes sure cars get info quickly, helping them perform better.

Use in Cars and Phones

HSD connectors are useful in both cars and phones. In cars, they link radios and screens. In phones, they help with signals. Picking the right one is key for good performance.

Other Special Connectors

Use in New Cars

New cars need special connectors for cool tech like smart driving tools and electric engines. Right connectors make these systems safe and easy to use.

New Connector Ideas

Connectors keep getting better with new ideas. They are stronger, smaller, and last longer now. These changes help them work well in new cars for a long time. Staying updated on these changes is important for car makers.

Industry Rules and Following Them

Industry rules are key for making good car connectors. They help makers create connectors that work well, keeping cars safe and efficient.

Why USCAR 2 Rules Matter

The USCAR 2 rule, made by the Society of Automotive Engineers (SAE), is a big guide for testing car connectors. It covers all steps from making to using them. It checks low voltage (0 - 20 VDC) uses in cars, making sure they work well in different situations.

Making Sure They're Strong and Trusty

USCAR 2 rules stress being strong and trusty for car connectors. By following these rules, makers can make sure their connectors handle tough conditions like hot or shaky places. This strength is important to keep car systems working right, stopping problems that could be unsafe.

Testing How They Work: USCAR 2 has tough tests to see if connectors last in real life. These tests check things like heat changes, shaking, and getting wet.

Picking the Right Stuff: The rule helps makers choose materials that make connectors last longer. Using stuff that doesn't rust or break easily keeps them working for a long time.

Benefits of Following the Rules for Makers

Following USCAR 2 rules gives many benefits to connector makers. By doing this, they can do better in the market and earn trust from buyers.

Getting Into Markets: Sticking to known rules helps enter world markets since many places need these performance checks.

Buyer Trust: Products meeting USCAR 2 are seen as more reliable, boosting buyer trust and brand image.

Saving Money: By using standard tests and ways to make them, makers can avoid product returns and save money on fixes.

In short, industry rules like USCAR 2 are vital for good car connectors. They give a plan for makers to make connectors fit for today's cars, helping make safer and better car systems.

Automotive connectors are important for car safety and work well. They keep parts connected and handle tough conditions, making them reliable. Rules like USCAR 2 help makers create strong connectors. These rules make sure connectors meet strict tests, building trust with buyers. In the future, new connector ideas will change cars more. Makers need to know about new trends to stay ahead and be creative. By focusing on good quality and following rules, they can help make safer and better cars that fit what people need today.

See Also

Significance of Fakra Auto Connectors in Contemporary Cars

The Significance of HSD Connectors in Auto Sector

Importance of Fakra Connectors in Auto Sector