The Necessity of OEM Connectors in Types of Wire Connectors Automotive

OEM connectors are very important in cars, as they are one of the key automotive electrical connectors types. They keep electrical systems safe and reliable. These connectors are carefully made for each vehicle's needs, and their design fits well with different car connector types. This helps the car's electronics work better and more efficiently. By following manufacturer rules, OEM connectors maintain the car's warranty and prevent potential hazards. They are manufactured to precise specifications to avoid connection problems, lowering repair costs and ensuring the car runs smoothly.

Benefits of Using OEM Connectors

Strong and Long-Lasting

Tough Against Weather

OEM connectors are very strong. They can handle tough weather. They work well in hot, cold, wet, and shaky places. This strength keeps them working right in cars. Special seals stop water and rust from getting in. OEM connectors are very strong.

Lasts a Long Time in Cars

OEM connectors last a long time. They are made to be tough for car use. This means you don't have to change them often. So, it costs less to keep the car working. Good materials help them last longer.

Fits Well and Works Great

Easy Fit with Car Parts

OEM connectors fit easily with car parts. This helps car electronics work well without problems. They match the car's original parts perfectly.

Better Work and Saves Energy

OEM connectors work well with high power needs. They are tested a lot to make sure they work for new car tech. These connectors help things like electric steering work better and save energy too.

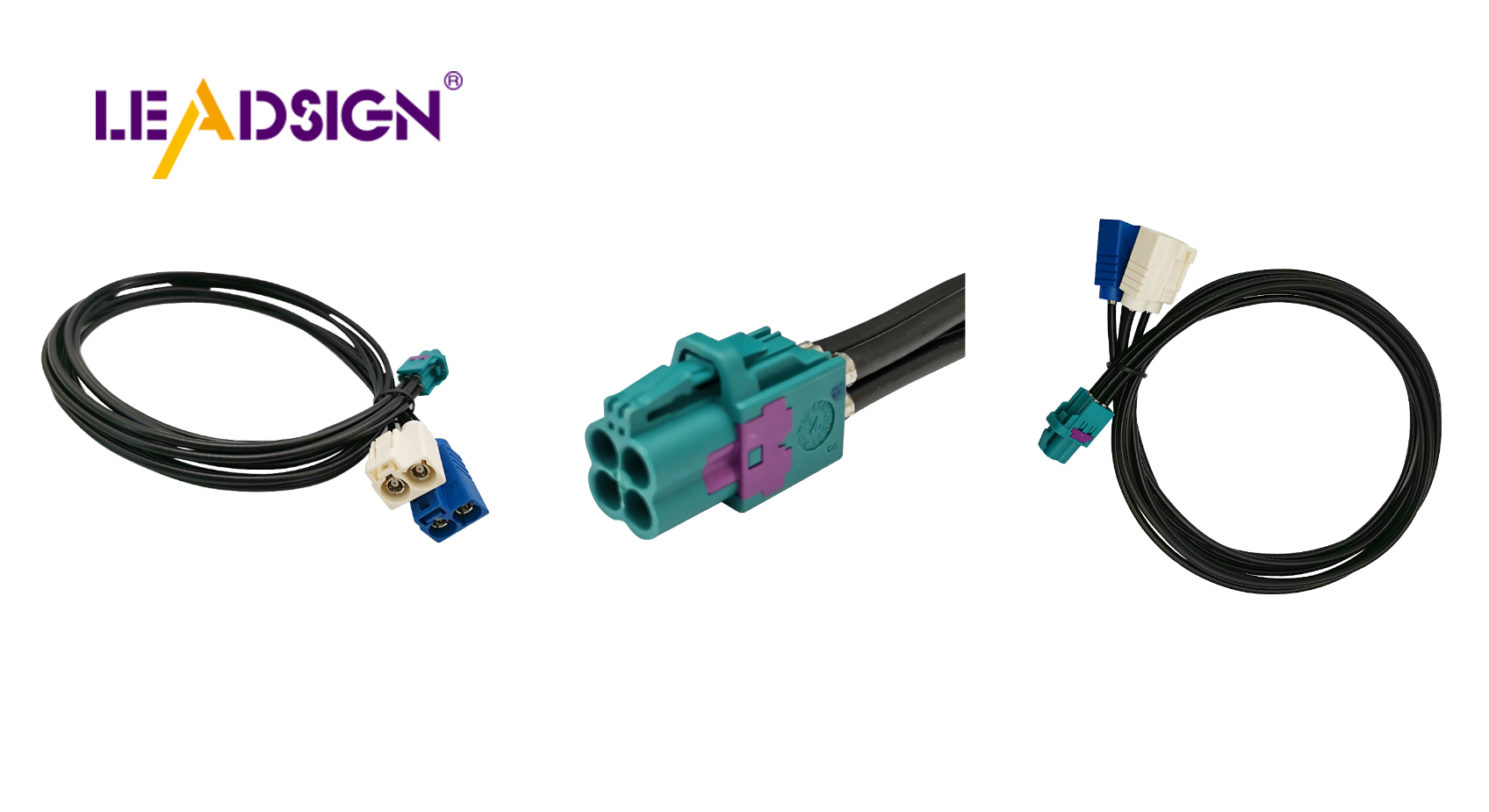

Types of Car Electrical Connectors

Car electrical connectors are very important. They help car parts work well together. These connectors make sure power and signals move smoothly in the car. Knowing about different connector types helps pick the right ones.

Power Connectors

Power connectors are key for car electricity systems. They send power from the battery to other parts. These connectors handle big power loads, helping the car run well.

Use in Battery and Power Sharing

Power connectors link batteries to important parts like starters and alternators. They keep connections safe and stop power loss. Their strong build handles bumps and temperature changes in cars.

Signal Connectors

Signal connectors help parts talk to each other in cars. They move data between electronic parts so everything works together.

For Talking and Data Moving

Signal connectors are used in radios, maps, and driver helpers. They send data fast between sensors, controls, and screens. Good shielding stops signal problems from outside noise.

Hybrid Connectors

Hybrid connectors mix power and signal jobs into one piece. This makes them useful for new car tech by reducing wire mess.

Mixing Power with Signal Jobs

Hybrid connectors are great when both power and data need moving at once. They're perfect for things like electric steering where good communication is needed. By mixing jobs, they make car systems simpler and better.

Best Ways to Install

Making Sure They Fit Right

Putting in OEM connectors right makes them last longer. Car fixers say using the right tools is key. Various Automotive Technicians say special tools help fit parts perfectly. If they don't fit well, things might not work.

Use the Right Tools: Use tools made for car connectors. These tools make sure parts fit snugly.

Follow Maker's Rules: Do what the maker says to do. This keeps things working and stops breaks.

Don't Tighten Too Much or Too Little: Tighten just enough as told. Too tight can break it, too loose can make it fall off.

Check and Fix Often

Checking and fixing OEM connectors often is important to find problems early. Various Automotive Technicians say regular checks keep the electric parts safe.

Check Connectors Often: Look for wear or rust often. Finding problems early saves money on fixes.

Strip Wires Right: Take off wire covers carefully before connecting them. This stops bad connections and shorts.

Check After Putting In: Look closely after installing them to ensure all fits well and works right.

By doing these steps, car experts can make sure OEM connectors work well, keeping the car's electric systems safe and good.

OEM connectors are key for car safety and performance. They make sure connections work well, lowering electrical problems. As cars get better, makers create new connectors with cool features. These have better seals, hold more power, and fit new tech. Future changes show a move to smart, fast, electric, and tiny parts. This change will make cars run better and last longer. By using these new ideas, car makers can keep improving safety and performance to meet what modern cars need.

See Also

Why Fakra Connectors Matter in Today's Automotive Sector

Benefits of HFM Connectors for Modern Vehicles

Significance of Fakra Connectors in Contemporary Cars