Understanding the Importance of OEM Car Wire Connector Types

OEM car wire connectors are one of the essential automotive electrical connectors types that play a crucial role in enhancing vehicle performance and safety. These connectors ensure secure connections, which significantly increases the reliability of cars. Although they may have a higher initial cost, they are designed for longevity and require fewer replacements over time. OEM connectors adhere to strict standards, allowing them to integrate seamlessly with various car systems, thereby enhancing safety and preserving the vehicle's warranty. This is why both manufacturers and consumers highly value them.

Benefits of Using OEM Car Connectors

Strong and Trustworthy

OEM car connectors are known for being strong and trustworthy. Makers test them a lot to make sure they can handle tough car conditions. They use materials that don't break easily, so they last a long time. This focus on good quality helps stop electrical problems, which can cause unexpected stops and safety issues. By picking OEM connectors, car owners save on repairs and get better reliability over time.

Keeping Safe

Safety is very important in cars, and OEM connectors help with this. These connectors follow strict safety rules to make sure connections are secure and reliable. This is important for things like electric steering and cool safety features to work right. By using these special connectors, both makers and users keep cars safe and working well, making driving better overall.

Types of OEM Automotive Electrical Connectors

OEM car connectors come in different types of OEM car connectors. Each type is made for certain jobs and places in a car. Knowing these helps pick the right one for best performance and safety.

Sealed Connectors

Sealed connectors are important where there's water, dust, or dirt. They use special seals like grommets and O-rings to keep water and dust out. This makes sure connections stay safe even when it's tough outside.

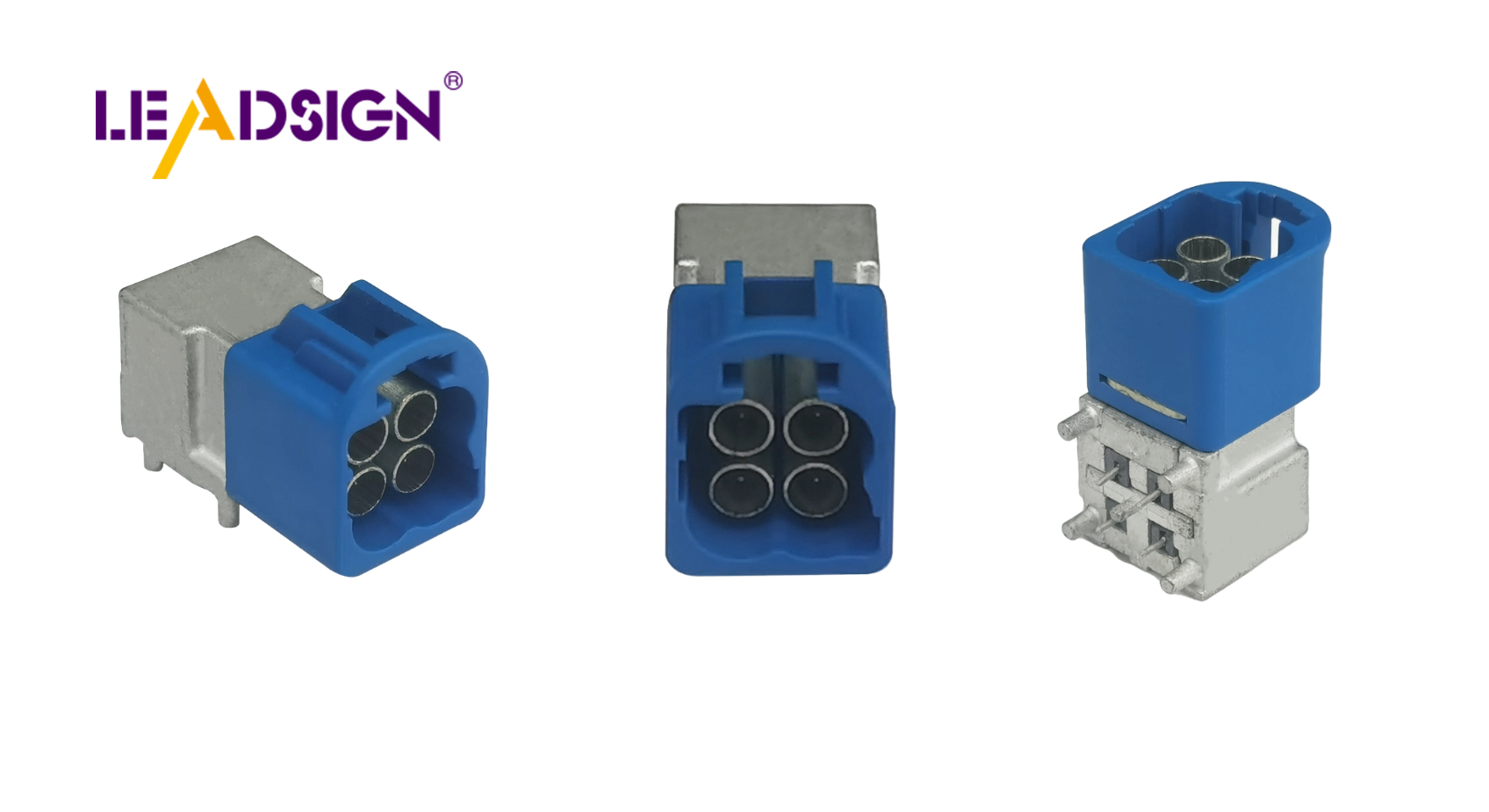

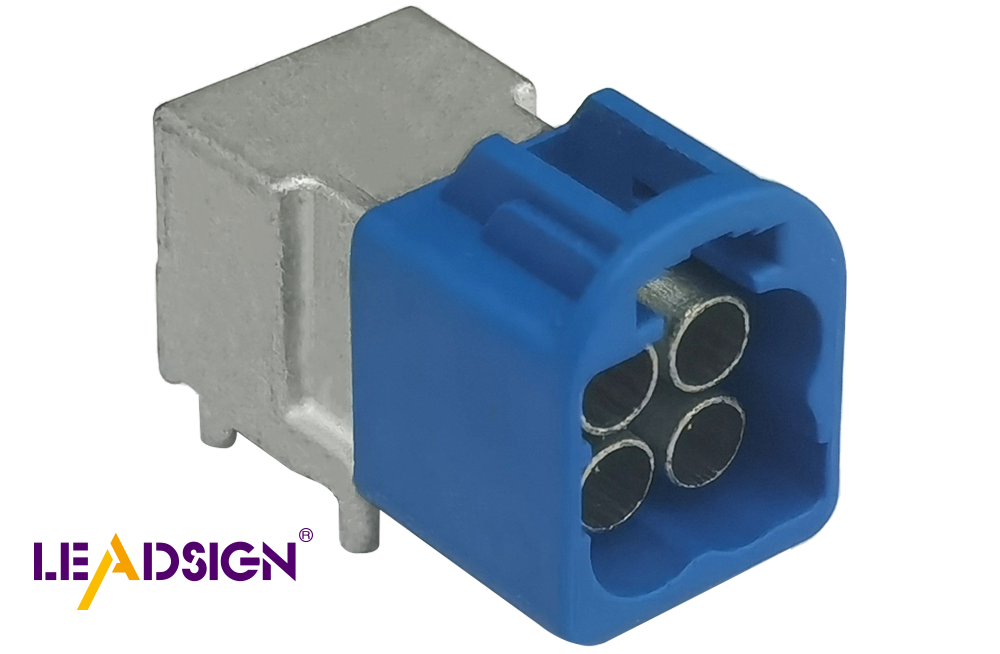

Product Information:

OEM Automotive Electrical Wiring Connectors: These are made to be very strong and last long. They cut down on repairs because they don't need changing often.

Sealed connectors are useful in parts of the car that face weather, like the engine area. By keeping dirt out, they stop short circuits and electric problems.

Unsealed Connectors

Unsealed connectors work where there isn't much water or dust. They're cheaper for places that don't need sealing. Even without extra protection, they still connect well if used right.

Product Information:

OEM Style Connectors: These make sure connections are safe and stop mistakes in wiring. They help keep systems working well.

Unsealed connectors are usually inside cars, like behind dashboards where it's dry. They're easy to use and save money, fitting many needs in cars.

Picking the right OEM connector helps cars run safely and well. Both sealed and unsealed types keep the car's electric system working properly.

Uses of OEM Connectors in Cars

OEM connectors are very important in cars. They make sure all the car's electrical parts work well together. These connectors are made just for certain car models. This means they fit perfectly and don't cause problems like other cheap parts might. Their design matches the car's special electric gadgets, so new parts or upgrades work smoothly with what's already there.

Engine and Power Systems

In engines, OEM connectors are super important. They keep sensors and control parts connected safely. This helps the engine get the right info it needs to run well and save fuel. By keeping good connections, these connectors stop problems like engine hiccups or wasting gas.

Sensors: OEM connectors join sensors to the engine's brain (ECU) for correct info sharing.

Control Parts: They link control parts that help engines work better and last longer.

Safety Systems

Safety systems in cars need OEM connectors a lot. These connectors make sure things like airbags, anti-lock brakes (ABS), and stability controls work right. By having strong links, they keep everyone safe inside the car.

Airbags: OEM connectors make sure airbags pop out right during crashes.

Anti-lock Brakes (ABS): They keep ABS working to stop wheels from locking when braking.

Stability Control (ESC): OEM connectors help ESC systems so drivers stay in control during quick moves.

OEM connectors are key in cars, making sure everything works safely and well together. Picking the right ones helps cars last longer without trouble.

Best Ways to Install OEM Connectors

Installing OEM connectors the right way helps them work well and last long. Following good steps during installation stops problems and makes these connectors more reliable.

How to Handle and Install Properly

Get Ready: Before starting, gather all tools and materials needed. Make sure connectors are clean with no dirt that can mess them up.

Line Up Right: Put connectors in the right spot to avoid breaking them. If they don't line up, it can cause bad connections and electrical problems. They should fit snugly without forcing.

Tighten Well: After lining up, fasten connectors tightly. Loose ones can cause electrical issues now and then. Use the right tools to make sure they're tight and steady.

Don't Over-tighten: Tightening is important, but too much can break them. Use the right force to keep connectors safe.

Wear Safety Gear: Gloves and insulated tools stop static electricity that might harm delicate parts.

Expert Advice: Eigen, a top name in car connectors, says keeping high standards when installing is key for safety and efficiency.

Regular Check-ups

Check Often: Look at connectors regularly for wear or damage early on. Check for rust or any harm that could hurt connections.

Keep Clean: It's important to keep dust off connectors as it affects how they work. Use cleaners made for this job.

Swap Bad Ones: If a connector looks damaged, change it right away to prevent bigger problems later.

Write It Down: Keep notes on checks and fixes to see how connectors hold up over time, helping plan future care or swaps.

Learn More: Train technicians often on new ways of installing and fixing so they know current industry rules.

By following these tips, car experts make sure OEM connectors work well, boosting vehicle safety and performance overall.

OEM connectors are very important for keeping cars safe. They fit well with the car's electric parts, making them work smoothly. Their strong build stops them from breaking easily, which keeps cars safe and working well. By following rules, these connectors fit perfectly and work without problems. To get the most out of them, it's important to install and take care of them properly. Doing this helps the car run well for a long time and stay safe.

See Also

Why Fakra Connectors Matter in Automotive Applications

Significance of HSD Connectors in Automotive Systems

Fakra Connectors: Essential for Today's Automotive Technology