Identifying Electrical Connectors with Custom Wire Harnesses

Finding the right types of connectors electrical is very important. It ensures your projects work well. Each connector has a special job. Knowing these jobs helps you pick the right one. Custom wire harnesses are important too. They enhance connections by fitting wires to specific uses. This improves system performance and lowers the chance of connector problems. These problems can be worse than regular wiring issues.

Key Takeaways

Understanding different types of electrical connectors, such as JST, DuPont, Molex, and FAKRA, is crucial for selecting the right one for your project.

Custom wire harnesses enhance system performance by ensuring connectors fit specific applications, reducing the risk of connection issues.

Identifying connectors can be simplified by examining their shape, size, and pin setup, making it easier to choose the correct type.

Utilizing resources like connector books and online searches can provide valuable information for accurately identifying connectors.

Collaboration with manufacturers is essential for designing effective custom wire harnesses that meet project requirements and industry standards.

Staying informed about new technologies and trends in connectors and wire harnesses can significantly improve project outcomes.

Types of Connectors Electrical

Knowing different connectors electrical is key for smooth projects. Each connector has its own job. Understanding them helps you choose wisely.

JST Connectors

JST connectors are loved by electronics fans and experts. You see them in gadgets with rechargeable batteries. They are also in 3D printers and remote-control toys. These connectors are trusted for good connections. They are popular in DIY projects. Their small size fits well in tiny devices. They help send power and signals efficiently.

DuPont Connectors

DuPont connectors are flexible and used a lot in testing. They connect easily to boards and parts. This makes them great for trying out circuits. They have different pin setups. You can change connections to fit your needs. They are easy to use, perfect for schools and hobby projects.

Molex Connectors

Molex connectors have many wire-to-board choices. They are good for strong and lasting connections. You find them in places needing reliability, like factories and cars. Molex connectors work in tiny and sealed spaces. They solve tricky wiring problems. Their tough design lasts long, even in hard conditions.

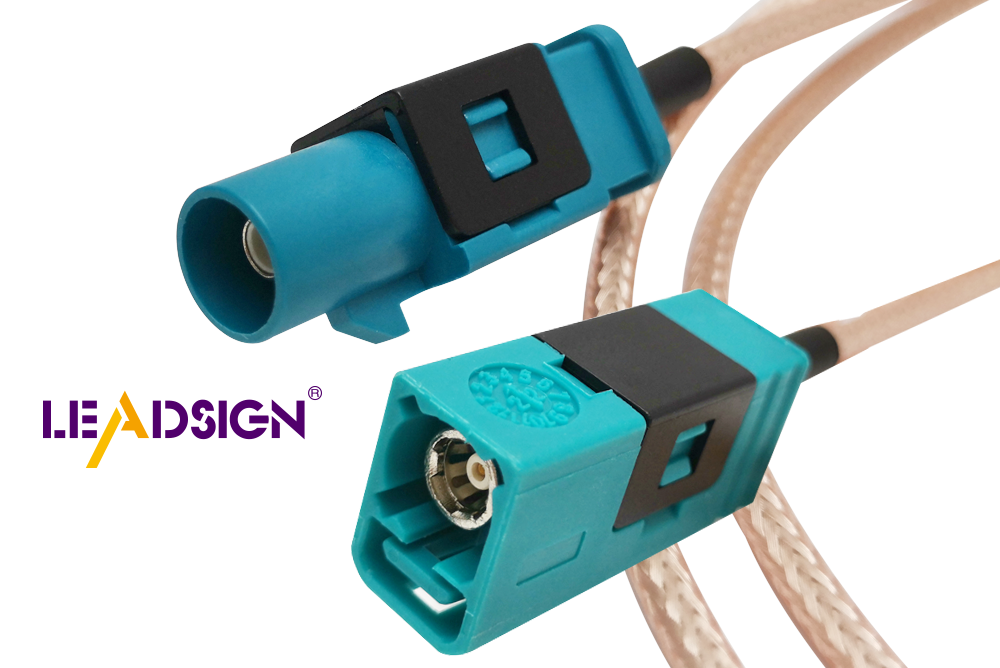

FAKRA Connectors

FAKRA connectors are important in car electronics. They are used in radios, GPS, and car tech. These connectors make sure connections are strong and safe. They meet the tough needs of car makers.

"FAKRA connectors are made to meet car industry needs. They give strong and lasting connections."

Some main features of FAKRA connectors are:

Secure Coding System: Stops wrong connections by matching only right parts.

High Assembling Security: Extra locks make connections more reliable.

Versatile Housing Options: Different designs save space and allow quick use.

Durability: They handle tough conditions, good for many car uses.

Uses of FAKRA connectors include:

Radio antennas

GPS systems

Car entertainment systems

Mobile devices

RF Bluetooth and WLAN uses

When using custom wire harnesses, knowing about connectors electrical like FAKRA is key. These connectors help signals work well and keep car systems safe and strong.

Ways to Identify Electrical Connectors

Finding the right electrical connectors is very important. It helps your projects succeed. Using good methods makes it easy to tell connectors apart and pick the right one.

Looking at Connectors

Looking at connectors is a simple way to know them. You can use their looks to tell them apart.

Shape and Size

The first thing you see is the shape and size. Connectors have different shapes that help you know them fast. Some are round, others are square. Bigger connectors might carry more power or data.

Pin Setup

Pin setup is also important. Count the pins and see how they are placed. This tells you the connector type. Some have one row of pins, others have many. This helps you know what the connector does and if it fits with other parts.

Using Tools and Help

Besides looking, you can use tools and help to know connectors better.

Connector Books

Connector books are helpful. They give details about connectors. These books have pictures and info that help you match your connector. This way, you pick the right one for your job.

Online Searches

Online searches are easy for finding connector info. You can type in details like shape or pin setup. Then, you find matches. This is good for quick and easy connector finding.

By using looks and tools, you can know different types of connectors electrical. This helps you pick the right ones, making your projects work better and last longer.

Role of Custom Wire Harnesses in Connector Identification

Custom wire harnesses help find the right connectors. They make sure each connector fits well. This part shows how custom wire harnesses help with finding connectors and making systems work better.

Importance in Connector Identification

Customization for Specific Applications

Custom wire harnesses can be made for your project needs. This lets you pick the right connectors for each job. Doing this makes sure connectors work their best. Custom wire harnesses are flexible. They let you change for different projects. This makes sure connectors fit your system's needs.

Enhancing System Efficiency

Custom wire harnesses make systems work better by making strong connections. Using the right connectors helps systems run smoothly. This lowers the chance of problems and stops. Custom wire harnesses also keep wires tidy. This neatness reduces mess and helps air move, stopping overheating. So, your system works better and lasts longer.

Designing Custom Wire Harnesses

Factors to Consider

Think about many things when making custom wire harnesses. First, think about where the harness will be used. Will it face heat or wetness? Next, think about what power it needs. Make sure it can handle the right voltage and current. Also, think about the space for the harness. Make sure it fits without hurting connectors.

Collaboration with Manufacturers

Working with makers helps design good custom wire harnesses. Makers know how to pick the right materials and connectors. They can tell you about new tech and trends. By working with them, your wire harnesses meet standards and work well.

Picking the right connectors is very important. It makes sure your projects work well. Here are some easy tips to help you:

Know What You Need: Find out what your project needs. This helps you pick connectors that fit just right.

Ask Experts: Get help from people like the Expert Engineers at Meridian Cable Assemblies. They know a lot about making custom wire harnesses.

Keep Learning: Stay updated on new tech and trends. The Experts at OurPCB Tech Ltd say knowing a lot helps make good custom wiring harnesses.

By using these tips, your project will work better and last longer.

FAQ

What should you think about when picking electrical connectors?

When picking electrical connectors, focus on these things:

Termination Types: Make sure the connector fits how you'll connect it.

Environmental Conditions: Think about where it will be used, like hot or wet places.

Material and Size: Choose materials that won't rust and fit the right size.

These things help the connector work well and stay safe.

How do custom wire harnesses make systems better?

Custom wire harnesses make systems better by:

Giving Special Solutions: They fit exactly what you need, making connectors work best.

Stopping Connector Issues: Custom ones lower the chance of wrong connections.

Boosting System Efficiency: They keep wires tidy, helping air flow and stopping overheating.

These perks make systems more reliable and last longer.

Why is it important for connectors to be reliable in machines and cars?

Connector reliability is key because:

Keeps Things Safe: Good connectors stop electrical problems that could cause accidents.

Makes Things Comfortable: They keep systems like AC and music working well.

Helps Things Last: Reliable connectors wear out less, making machines and cars last longer.

Good connectors are needed for safety and performance.

How can you tell different connectors apart by looking?

You can tell connectors apart by:

Shape and Size: Each connector has a special shape and size for easy spotting.

Pin Setup: Count and look at pin layout to know the type.

Color-Coding: Some use colors to show what they do or fit with.

These clues help pick the right connector.

How do connector books and online sites help in finding connectors?

Connector books and online sites help because they:

Give Lots of Info: They have details and pictures to match connectors.

Make Searching Easy: Look by shape, size, or pins to find the right one.

Have New Info: They show the latest on new connectors and tech.

These tools make finding the right connectors simple.

How do weather and surroundings affect connector choice?

Weather and surroundings affect connector choice by:

Changing Material Needs: Connectors must handle heat, wetness, and rust.

Deciding Strength Needs: Tough places need strong connectors.

Impacting Performance: The right connector keeps working well even in tough spots.

Thinking about these helps pick the right connectors.

Why work with makers when designing custom wire harnesses?

Working with makers is good because they:

Know a Lot: Makers know the best materials and connectors for you.

Ensure Quality: They help make harnesses that meet rules and work well.

Share New Tech: Makers tell you about new connector tech.

Working with them makes sure your harnesses are good and reliable.

What are the good things about using FAKRA connectors in cars?

FAKRA connectors are good in cars because:

Strong Connections: They use codes to stop wrong connections.

Safe Assembly: Extra locks keep connections strong.

Flexible Designs: Different looks save space and are easy to use.

Toughness: They handle hard conditions, great for car use.

These make FAKRA connectors a top pick for cars.

How do you keep electrical setups safe and working well with connectors?

To keep setups safe and working well, you should:

Pick the Right Connector: Match it to your project's needs and surroundings.

Use Good Connectors: Pick ones known for being strong and working well.

Follow Install Rules: Stick to tips for putting in and keeping connectors.

These steps keep setups safe and working well.

What tips help in picking and using connectors with custom wire harnesses?

Here are some tips:

Know Your Needs: Find out what your project needs to pick the right connectors.

Ask Experts: Get advice from people who know custom wire harnesses.

Stay Updated: Keep learning about new connector tech and trends.

These tips help your projects work well and last.

See Also

Understanding HSD Connectors Essential for Automotive Applications

An In-Depth Overview of HSD Connectors Explained

Why HSD Connectors Are Crucial for Automotive Success