Identifying Types of Wire Connectors Automotive for Easy Replacement

Finding the right automotive electrical connectors types is important. They keep your car safe and working well. Wrong connectors can cause electrical problems. These problems make up 45% of high-voltage connector issues in cars. Such issues are dangerous. You need help to know different automotive electrical connectors types for good replacements. This helps you avoid mistakes and keeps your car running smoothly. By learning about these connectors, you can choose wisely and keep your car reliable.

Knowing Car Electrical Connectors

In car repair, knowing electrical connectors is important. They help your car's systems work right. Let's look at some common types and what they do.

Common Connector Types

Blade Connectors

Blade connectors are used a lot in cars. They have a flat metal piece that fits into a slot. You see them in fuse boxes and other parts. They connect and disconnect easily, which is good for places needing frequent checks.

Bullet Connectors

Bullet connectors are round and join wires in cars. They fit tightly into sockets for a secure hold. These are often found in lights and low-power areas. Their simple design makes them easy to use for beginners.

Pin Connectors

Pin connectors can handle high power needs. You might find them in headlights or starters. They have pins that fit into holes, making strong connections needed for important car parts.

Jobs of Different Connectors

Power Sharing

Car connectors help share power around the car. They send power to things like the engine system or music system. For example, pin connectors are used where lots of power is needed.

Signal Sending

Connectors also send signals between car parts, like sensors to control units. This job is key for things like GPS or driver help systems, where good data sending is needed.

Knowing these connector types helps you pick the right ones when fixing your car. Choosing well keeps your car safe and working fine.

Steps for Finding Connectors

Finding the right automotive electrical connectors is key for fixing cars. Follow these steps to pick the right ones.

Looking at Connectors

First, look closely at the connector. This helps you learn what type it is.

Checking Shape and Size

Check how the connector looks. Different connectors have different shapes and sizes. Blade connectors are flat, while bullet ones are round. By comparing shapes and sizes, you can find out which one it is.

Noticing Colors

Next, see what color the connector is. Many connectors use colors to show what they do or if they fit. Some colors mean power, others mean signals. Knowing these colors helps you figure out the type.

Counting Pins and Using Manuals

After looking, count how many pins there are. This helps match it with the right kind.

Using Car Books

Look in your car's book (manual). It tells about the automotive electrical connectors in your car. Match pin numbers and shapes with what's in the book to find the right one.

Online Help

If books don't help, check online sites. Many websites let you search by pin number, shape, and color. These sites help find the right automotive electrical connectors for your car.

"Ask a pro if unsure about which connector to use." - Connector Experts

If confused, ask experts like Connector Experts for help. They can tell you which connector fits by checking pictures of yours. This keeps your car safe and working well.

By doing these steps, you'll know which automotive electrical connectors your car needs. This helps make smart choices when fixing cars so they stay safe and work fine.

Tools and Ways to Identify Connectors

Finding the right automotive electrical connectors is important for your car. Using the right tools makes this job easier. Let's look at some helpful ways.

Testing with Multimeters

A multimeter is a must-have tool for car connectors. It checks if connectors work by measuring voltage and continuity. Here's how to use it:

Check Voltage and Continuity:

Set the multimeter to voltage or continuity.

Put the probes on connector ends.

Look at the numbers. Good voltage means it works, while continuity shows a complete path.

"Testing wires with a multimeter is useful for any car fan." - Patent Abstract

A multimeter helps find and fix electrical problems fast. This tool makes sure your automotive electrical connectors work well, stopping issues before they start.

Connector Kits

Connector kits help find the right automotive electrical connectors. These kits have tools that help match and identify connectors easily.

Why Use Kits?

Different Terminal Types: Kits have many terminal types to compare with your car's connectors.

Labeled Sections: Kits have labeled spots, making it easy to sort different connector types.

Simple Use: Kits make finding connectors quick and easy.

"Test Kits come with many terminals, helping you match them." - Patent Abstract

Using these kits helps pick the right automotive electrical connectors for your car. This keeps your car's electric system safe and reliable.

By using these tools, you can better find and change car connectors. Knowing this helps keep your vehicle in great shape.

Deciding to Fix or Replace Connectors

Checking Connector Condition

Before fixing or changing car connectors, check their condition. Look for damage signs.

Damage Signs

Corrosion: See if metal parts are rusty or discolored. Rust can cause bad connections.

Cracks or Breaks: Check plastic parts for cracks or breaks. These let water and dirt in.

Loose Connections: Move the connector gently. If it wiggles, it may not connect well.

Burn Marks: Look for burn marks or melted spots. These show overheating, which is risky.

If you see these signs, think about replacing the connector to keep your car's electrical system working right.

Thinking About Costs

After checking conditions, think about repair versus replacement costs.

Repair vs. Replacement Costs

Repairing Connectors: Fixing can be cheaper if damage is small. You can change pins or wires without a new connector, saving money and materials.

Replacing Connectors: Sometimes you need a new connector due to wear from use or accidents. New ones keep your car safe and running well.

"Instead of changing all wires, fix damaged connectors by re-pinning or wire repair for less cost."

When picking between OEM and aftermarket connectors, think about long-term costs. OEM connectors have warranties and good quality but cost more at first but save money later on. Aftermarket connectors cost less now but might lack quality and warranty, leading to more fixes later.

By checking condition and costs, you decide smartly on fixing or replacing car connectors. This keeps your vehicle safe and reliable.

Safety Tips and How to Replace Connectors

When changing car electrical connectors, safety comes first. Use the right tools and follow steps for a good job.

Tools You Need

To change connectors well, have these tools:

Wire Strippers: They take off wire covers without harm. Clean ends are needed for good links.

Crimpers: These attach connectors to wires tightly. A strong hold makes sure electricity flows well.

"Picking the right automotive electrical connectors is key for your car's electric parts." - LEADSIGN-AUTO

Having tools ready makes changing connectors easier and safer.

Steps to Change Connectors

Follow these steps to change car connectors right:

Taking Off Old Connector

Turn Off Power: Before starting, turn off the car's power. This stops shocks or harm.

Find the Connector: Locate the connector you need to change. Check your car book if unsure.

Remove It Carefully: Gently take off the old connector. Don't pull wires directly to avoid damage.

Check Wires: Look for wear or damage signs. If needed, strip wire ends with strippers.

Putting On New Connector

Get New Connector Ready: Pick the right connector type for your car. Make sure it fits like the old one.

Attach It Well: Use crimpers to fix new connector on wire ends tightly and firmly.

Test It Out: Turn power back on and test new connector works fine with no loose parts.

"Talking with experts can help when finding hard-to-identify connectors." - Experts and manufacturers

By doing these steps, you make sure of a safe replacement process. Right tools and ways stop electric problems and keep your car safe.

Finding and changing car wire connectors needs some steps. First, look at the connector to know its type. Count the pins too. Use tools like multimeters and kits for checking. Always be safe by turning off power first. If unsure, ask an expert for help. Using right connectors makes cars safer and work better. Follow these tips to keep your car reliable and avoid problems. The right choice keeps your car running well and safely.

See Also

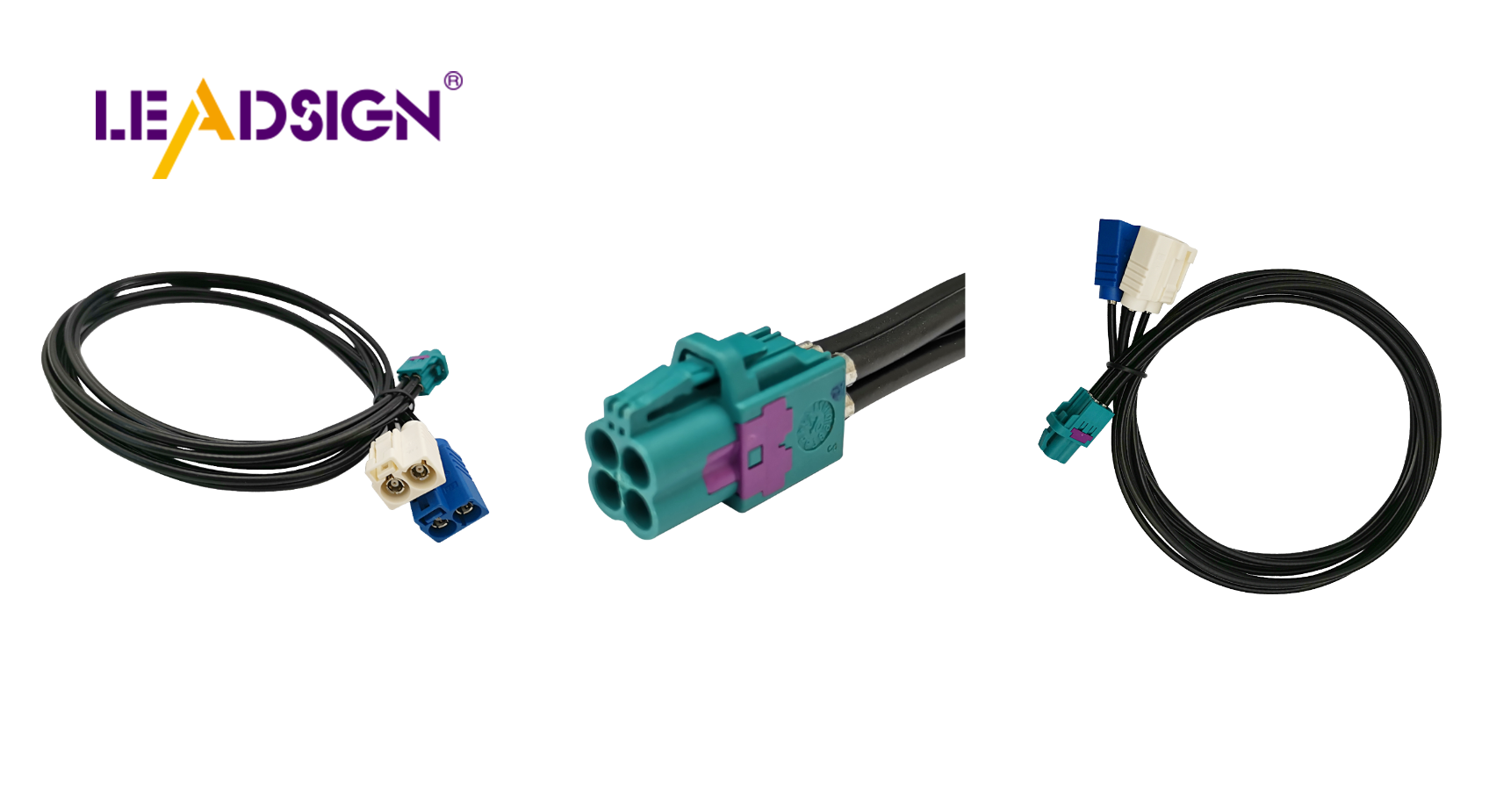

Understanding HSD Connectors Essential for Automotive Applications

Significance of FAKRA Connectors in Vehicle Technology

Benefits of HFM Connectors for Automotive Systems