How to Identify Vehicle Connectors for Accurate Replacement

Knowing the right vehicle connectors is very important. If you mix them up, it can cost a lot to fix. Look at the shape, size, and pin count of connectors. These help make sure they fit and work well. Many people have problems because of bad connectors. This shows why it's important to know them well. By learning these basics, you can stop problems and keep your car working well.

Key Takeaways

Understanding vehicle connectors is crucial for ensuring proper fit and function, preventing costly repairs.

Count the pins on connectors to identify their type and function; more pins often mean better performance in complex systems.

Use a multimeter to test connectors for voltage, current, and resistance, ensuring they are functioning correctly.

Refer to connector guides and manuals for visual comparisons and specifications to select the right connectors for your vehicle.

Differentiate between male and female connectors to avoid mismatches and ensure safe electrical connections.

Follow a step-by-step process for changing connectors, prioritizing safety by disconnecting the battery and using the right tools.

Regularly inspect and maintain connectors to extend their lifespan and prevent electrical issues in your vehicle.

Basics of Identifying Automotive Electrical Connectors

Knowing how to spot car electrical connectors is key. It helps make sure they fit and work right. Connectors have different shapes, sizes, and pin setups. Each one has a job to do. By learning about them, you can choose the right ones when changing or upgrading.

Counting Pins

Counting pins is a first step in spotting car connectors. Each pin is a contact point for electricity or data. The number of pins changes based on what the connector does. For example, a pigtail connector used in headlights may have many pins. This ensures a strong and good connection.

When counting pins, think about pin density too. More pins mean better signal and more uses. This is helpful in complex car systems where many functions work together.

Deciphering Shapes and Colors

The shape and color of connectors give more clues. Connectors can be round, triangle, rectangle, or square. Each shape fits certain sockets for a safe connection. For example, socket connectors are often round or rectangle.

Colors help tell connectors apart. Makers use colors to show what they do or what they fit with. By looking at these clues, you can find the right connector fast.

Tools and Ways to Find Car Electrical Connectors

Finding car electrical connectors needs the right tools and ways. These tools help you pick the right connector for your car. Using these ways, you can avoid big mistakes and keep your car running well.

Using a Multimeter

A multimeter is a key tool for checking connectors. It checks voltage, current, and resistance. With a multimeter, you can see if a connector works right. This tool helps find problems with your car's electrical parts. For example, with a pigtail connector, use a multimeter to check each pin's signal. This step is important to keep your car's electrical system safe.

To use a multimeter, do these steps:

Set the Multimeter: Pick the right setting—voltage, current, or resistance.

Connect the Probes: Put the probes on the connector's pins.

Read the Measurements: Look at the numbers on the multimeter. Compare these to what your connector should show.

By doing these steps, you can test car electrical connectors and make sure they work right.

Connector Guides and Manuals

Connector guides and manuals are helpful for finding car connectors. These guides have pictures and details to help you know different connectors. They give info about the shape, size, and pin setup of each connector. This info is key when picking the right connector for your car.

When using a connector guide, think about these:

Visual Comparison: Match your car's connector with the guide's pictures.

Read Descriptions: Look at the descriptions to know the connector's job and fit.

Check Specifications: Make sure the connector's details match your car's needs.

By using connector guides and manuals, you can find and pick the right car electrical connectors. These tools make it easy and lower the chance of mistakes.

Telling Apart Male and Female Car Connectors

Knowing the difference between male and female connectors is important. These connectors help your car's electrical parts work right. By seeing how they are built and what they do, you can pick the right ones when changing them.

How They Look

Male and female connectors look different. Male connectors have sticking-out pins or blades. These fit into female connectors, which have holes or slots. This makes sure they connect well. When you look at a pigtail connector, the male side shows metal parts. The female side has slots to hold these parts.

This design stops wrong connections. This keeps car connectors working well. Connector Experts say good quality is key:

"Good connectors are very important. Bad ones can break and make cars unsafe."

Picking connectors from good brands keeps them strong and less likely to fail.

What They Do

What male and female connectors do is also important. Male connectors give power or signals. Female connectors take them. This is important for cars to work well.

In cars, male and female connectors send signals and power. For example, a pigtail connector uses both to link things like lights or sensors. Knowing this helps you make sure each connector does its job right.

When picking car connectors, think about how they look and work. This helps you choose the best ones for your car to keep it running smoothly.

Step-by-Step Guide to Changing Car Connectors

Changing car connectors needs careful work. Follow these steps to do it right and keep your car's electrical parts safe.

Safety First

Safety is most important when working with car connectors. Before starting, disconnect the battery to stop shocks or short circuits. Wear gloves and goggles to stay safe from dangers. A Maintenance Technician once said:

"Following safety rules is very important, especially in risky situations."

By being safe, you protect yourself and your car from harm.

Tools Needed

Having the right tools makes changing connectors easier. Get these tools ready:

Screwdrivers: To loosen and tighten screws.

Wire Strippers: To take off wire covers.

Crimping Tool: To secure wire ends.

Multimeter: To check if connectors work.

Replacement Connectors: Make sure you have the right male and female ones for your car.

These tools help you work with connectors well.

How to Change Connectors

Follow these steps to change your car connector:

Find the Connector: Locate the broken connector in your car. Check its shape, size, and pins to get the right new one.

Take Out the Old Connector: Carefully remove the old connector. Release any locks. Use a screwdriver if needed to gently pull it apart.

Get Wires Ready: Strip the wire ends using wire strippers. Make sure the wires are clean and not damaged.

Put on the New Connector: Insert the wires into the new connector. Use a crimping tool to hold the wires tight.

Check the Connection: Use a multimeter to see if the new connector works. Make sure it sends signals right.

Put Back and Secure: Once happy with the connection, put back any parts you took off. Secure the new connector so it fits well.

By doing these steps, you can change your car connectors confidently. This keeps your car's electrical system working well.

Tips for Picking and Caring for Car Connectors

Picking the right car connectors helps your car's electric parts work well. By choosing good ones and taking care of them, you can stop problems and make them last longer.

Picking Good Connectors

When picking car connectors, choose good ones. Good connectors keep your car safe and working well. They lower the chance of breaking, which can cost a lot to fix. OEM wiring connectors are often a good pick. They follow rules and are tested a lot. Other connectors might not be as good.

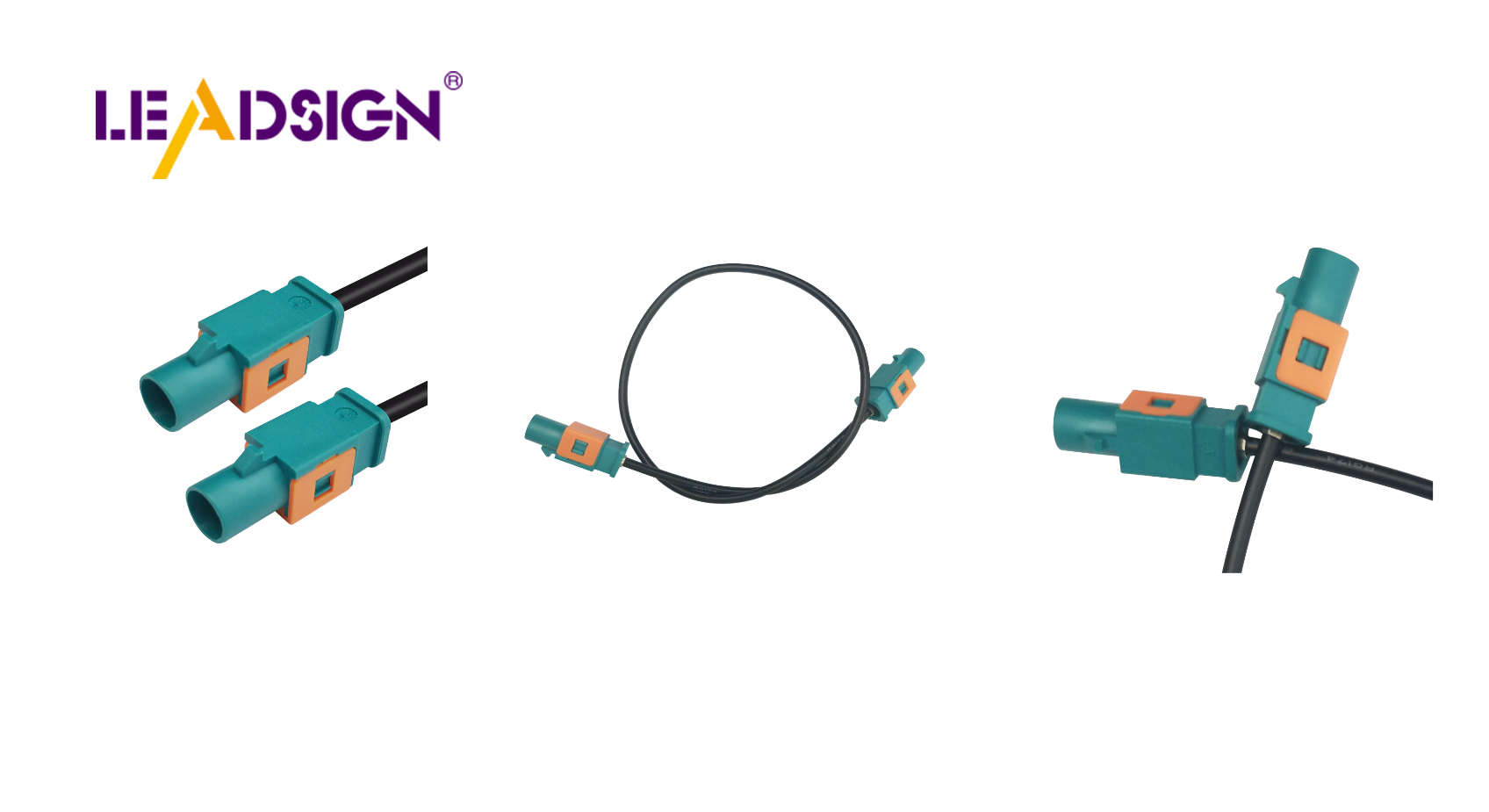

Think about what the connectors are made of. Ones with low contact resistance and good materials, like gold or silver, keep signals strong. This is important for your car's systems to work right. Brands like LEADSIGN are known for being good and strong, so they work in many cases.

"Good connectors are very important. Bad ones can break and make cars unsafe."

This shows why buying good connectors is smart. By picking from good brands, you make sure they last and don't break easily.

Taking Care of Connectors

Taking care of your car connectors is as important as picking them. Regular care keeps them working well and stops problems. Here are some tips:

Check Often: Look at your connectors for wear or damage. Check for rust, loose parts, or broken wires. Finding problems early stops bigger ones.

Clean Gently: Dirt can make connectors work badly. Use a soft brush or air to clean them. Don't use strong cleaners that might hurt them.

Keep Connections Tight: Make sure all parts fit well. Loose parts can make things work badly or break. Pay close attention to male and female connectors, as they need to fit just right.

Keep Dry: Water can rust and hurt wires. Use covers or sealants to keep them dry, especially where water might get in.

By doing these care tips, you can make your car connectors last longer and keep your car's electric parts working well.

Knowing the right car connectors is very important. It helps your car work well. Make sure each connector fits and works right. Check them often for dirt or damage. Use good cleaning tools to keep them clean. Clean connectors help your car last longer. Follow these tips to stop electrical problems in your car.

FAQ

What are the three types of automotive connectors?

Car connectors come in different shapes. They each have a job. The three main types are:

Pin/Pigtail Connectors: These have many pins. They are used in things like headlights.

Blade Connectors: These are flat and look like blades. They are used in car wiring.

Bullet Connectors: These are round and fit into matching sockets. They make a strong connection.

Knowing these helps you pick the right one for your car.

How can I identify common signs of faulty connectors?

Bad connectors can cause big problems in cars. Look for these signs:

Intermittent Electrical Problems: Lights flicker or signals act weird. This means a connector might be loose or rusty.

Visible Corrosion or Rust: Look for color changes or stuff on the connector.

Physical Damage: Cracks or breaks can make connections bad.

Check often to find these problems early and stop more damage.

Why is it important to differentiate between male and female connectors?

Male and female connectors do different things in cars. Male connectors have pins that stick out. They fit into female connectors with slots. This makes sure they connect well. Knowing this helps you pick the right type. This stops wrong matches and electric problems.

What tools do I need to replace automotive connectors?

Changing connectors needs special tools. These tools help them fit and work right. You need:

Screwdrivers: To loosen and tighten screws.

Wire Strippers: To take off wire covers.

Crimping Tool: To hold wires in the connector.

Multimeter: To check if the connector works.

Having these tools makes changing connectors easier.

How do I maintain my vehicle connectors?

Taking care of connectors makes them last longer. Follow these tips:

Regular Inspections: Look for wear, rust, or damage.

Gentle Cleaning: Use a soft brush or air to clean dirt.

Secure Connections: Make sure all parts fit tight.

Moisture Protection: Use covers to keep them dry and rust-free.

Regular care stops common connector problems and keeps your car running well.

See Also

Understanding Ford Fakra Connectors: A Comprehensive Guide

Why Honda Vehicles Rely on Fakra Connectors

Fakra Connectors: Essential for Today's Automotive Technology

Key Role of FAKRA Connectors in Automotive Systems

Enhancing Data Transmission in Vehicles with Advanced Connectors