How to Identify Types of Wire Connectors Automotive for Replacement

Identifying the correct types of wire connectors automotive for your vehicle is crucial. Using an incorrect type can lead to loose connections or electrical issues, which may escalate into more significant problems over time. This guide assists you in understanding the various types of wire connectors automotive, simplifying the replacement process. Being aware of what to look for makes it easier to maintain your car's electrical systems effectively. Let's explore and ensure you have the right knowledge for a successful replacement.

Knowing Wire Connectors for Cars

When changing car wire connectors, it's important to know the types of wire connectors. Each type has a job and keeps wires connected well. Let's look at some common wire connectors you might find.

Different Wire Connectors

Butt Connectors

Butt connectors link two wires. You put each wire in and squeeze it tight. They are great for joining wires in small spaces.

Ring Terminals

Ring terminals have a round end that fits on a bolt or screw. Use them to attach wires to a post. They give strong connections and are often used for grounding.

Spade Terminals

Spade terminals, or fork terminals, have split ends. This shape lets you easily attach and remove wires from blocks. They're handy when you need to disconnect often.

Bullet Connectors

Bullet connectors have male and female parts that snap together. They allow quick disconnections, perfect for frequent connect-disconnect tasks.

Connector Materials Matter

The material affects how well a connector works and lasts. Here are some materials used in car wire connectors.

Copper Connectors

Copper ones conduct electricity well and don't rust easily. They're popular in cars because they connect electricity efficiently.

Aluminum Connectors

Aluminum is light and cheap but less conductive than copper. It's good when weight matters more than conductivity.

Plastic Insulation

Plastic covers metal parts of connectors, stopping short circuits and keeping out moisture.

Where They're Used in Cars

Wire connectors are key in many car systems. Here’s where they’re commonly used in cars:

Electrical Systems

Connectors help power move smoothly through the car's electrical system, linking battery, alternator, and other parts.

Lighting Systems

In lighting systems, they join wires to lights like headlights and taillights so they work safely.

Audio Systems

For sound systems, connectors link speakers, amps, and head units to keep sound clear without losing quality.

Knowing these car wire connector types helps you pick the right one when replacing them. The right choice keeps your car's electrical systems safe and reliable.

Steps to Find the Right Connector for Replacement

When changing car wire connectors, you must find the right type. This part will show you how to choose well.

Checking the Old Connector

Look at your old connector before replacing it. This helps know what you need.

Looking Closely

First, check the connector by looking at it. See if there are cracks, rust, or burnt plastic. Notice its shape and color. These clues help find the exact type of connector you need.

Testing with a Meter

Next, use a multimeter to test if electricity flows through it. If it shows a break, the connector might be bad. This step makes sure you only change broken ones.

Finding What Type You Need

After checking your old one, decide what new type is needed.

Comparing Types

Find out what type by comparing with known types of connectors. Look at shapes and pins. These details help match them correctly.

Thinking About Wire Size

Think about wire size when picking a connector. The size affects fit and work quality. Make sure they match to avoid loose wires or problems.

Picking Good Connectors

Choosing good connectors is important for safe replacement.

Brand Advice

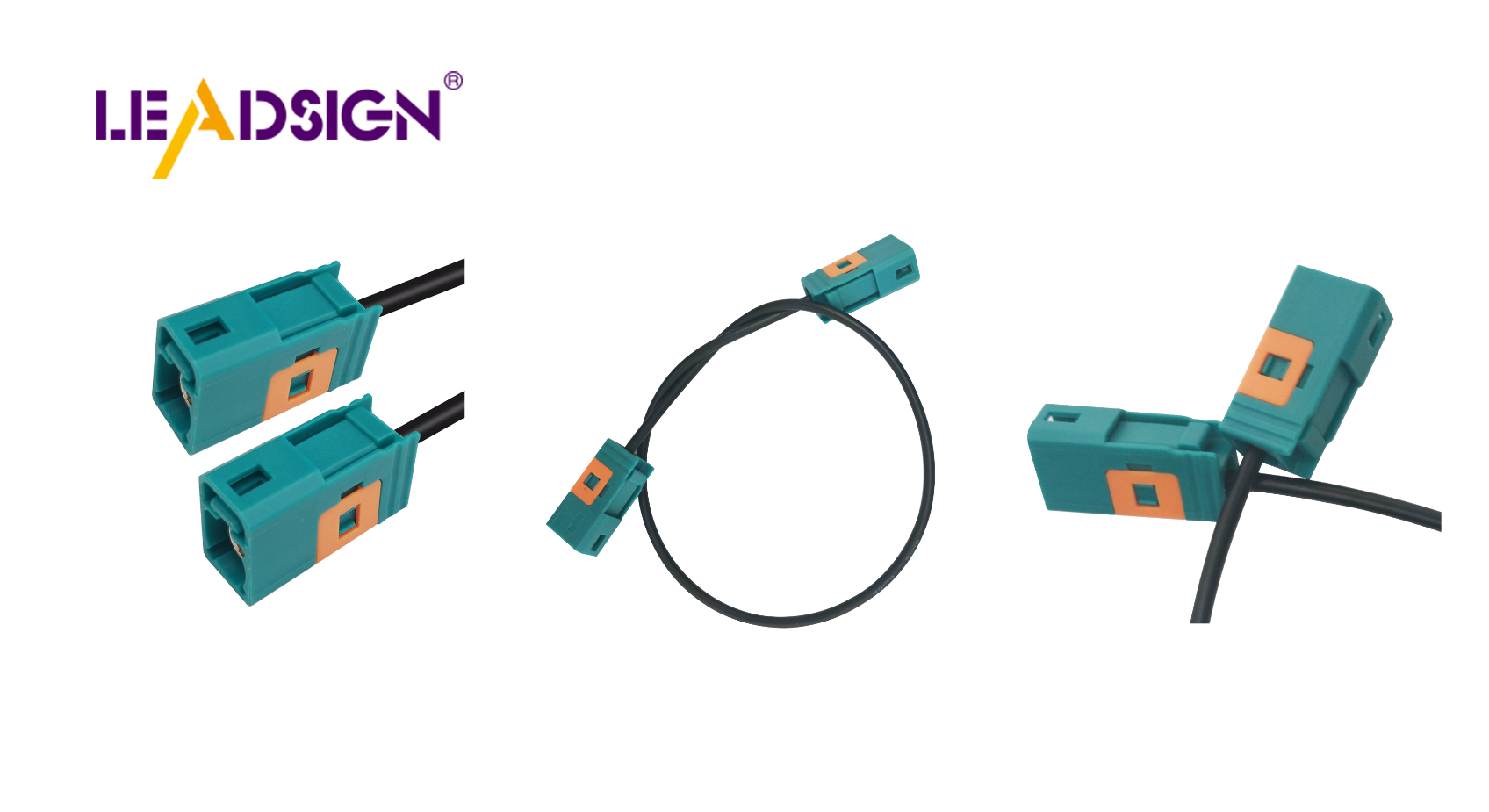

Choose brands known for strong connectors like LEADSIGN. Good brands meet standards and last longer.

Looking for Safety Marks

Check for safety marks on connectors like RoHS or ELV. These show they are safe and eco-friendly. Certified ones ensure safe use in your car.

By following these steps, you can pick and replace the right car wire connectors easily. This keeps your car's electrical parts working well and safely.

Safe Replacement Tips

When changing car wire connectors, safety is most important. Here are some tips to keep you safe.

Safety Steps

Before starting, take steps to stay safe and protect your car.

Power Off

Always turn off power before touching wires. This stops shocks or sparks. Find the battery and take off the negative cable. This makes sure no electricity flows while you work.

Right Tools

Using good tools makes work easy and safe. Get wire strippers, crimpers, and a multimeter. These help handle wires without harm. Don't use wrong tools; they can cause bad connections or hurt you.

Strong Connections

Good connections make your car's electrical parts work well.

Crimping Right

Crimping means squeezing a connector onto a wire tightly. Use the right tool for your connector type. Put the wire in place and press hard with the tool. A good crimp feels firm and won't come apart easily.

Soldering Help

Soldering adds extra strength to connections. Heat the iron and touch it where wire meets connector. Add solder so it covers well, then let it cool fully before moving it to avoid weak spots.

By using these safety tips, you can change connectors safely in your car. This keeps you safe and ensures your car works well.

Picking the right wire connectors for your car is important. It keeps your car's electrical parts working well and safely. Here are some last tips to help you:

Check Compatibility Twice: Always match the connector type and wire size.

Use Good Tools: Buy quality tools for crimping and soldering.

Be Safe: Turn off power before starting any work.

If you're not sure, ask a professional for help. It's better to be safe than sorry. With these tips, you're ready for a successful replacement!

See Also

Exploring HSD Connectors in the Auto Sector

Navigating Ford Fakra Connections

The Significance of FAKRA in Auto Tech