How to Identify and Replace Automotive Wiring Connector Types

Understanding different automotive electrical connectors types is crucial for maintaining your car's electrical components. These connectors play a vital role in ensuring secure connections, preventing issues such as shorts or fires. Opt for high-quality connectors to enhance the longevity and performance of your vehicle. Prioritize safety when dealing with car wiring by always powering off before handling any connectors. Wear appropriate safety equipment to protect yourself from potential harm. Regularly inspect connector parts for signs of wear or damage to address any issues promptly, ensuring the safety and proper functioning of your car.

Finding Car Electrical Connectors Types

Knowing car electrical connectors is important for fixing wires. These connectors help your car's electric parts work well and safely. Let's learn about some common types and how to spot them.

Common Car Electrical Connectors Types

Blade Connectors

Blade connectors are flat and slide into a slot. They are easy to use and reliable in cars. You see them in different sizes, often with fuses and relays.

Bullet Connectors

Bullet connectors are round and fit into a socket. They connect securely, used in car lights. Their design allows quick disconnection, good for frequent checks.

Pin Connectors

Pin connectors have many pins that fit into holes. They are used in many car parts, like engine systems. Count the pins to identify them.

Tools for Finding Them

Using a Multimeter

A multimeter helps find out if connectors work right by checking voltage, current, and resistance. Test each pin with it to ensure they connect well.

Connector Guides

Connector guides show details about different types with pictures and info. Keep one nearby for quick help during fixes or changes.

Tips for Correct Finding

Looking Closely

Check the connector’s shape, color, and pin setup carefully. Look for special features like tabs or keys. Small differences can tell similar ones apart.

Checking Manufacturer Info

Look at the maker's info for correct finding. These papers show important details on design and use. If unsure, ask experts or makers for help.

Steps to Change Car Wiring Connectors

Changing car wiring connectors needs careful steps for safe fixing. Follow these rules to change connectors in your car well.

Getting Ready to Change

Get ready before starting to make changing easy.

Collecting Needed Tools

First, gather all tools you need. Important tools are:

Wire strippers: To take off wire covers.

Crimping tool: For attaching new connector to wire.

Screwdrivers: To loosen or tighten screws on connectors.

Multimeter: To check electricity flow and ensure good connections.

Having these tools helps do the job faster.

Keeping Safe

Safety is very important with car wiring connectors. Always unplug the battery to stop shocks or shorts. Wear safety gloves and goggles to avoid getting hurt. Make sure your work area is bright and has no fire risks.

Taking Off Old Connectors

After getting ready, carefully take off old connectors.

Cutting Power Source

First, cut the power source. This stops electrical dangers. Find the battery and remove the negative end to stop power.

Using Right Tools for Taking Off

Use right tools to remove old connectors. A screwdriver can help loosen screws holding it. Gently pull apart connector without breaking wires. If stuck, use a little oil to help remove it.

Putting On New Connectors

With old ones gone, put on new connectors now.

Picking Right Connector Type

Pick correct connector type for your use. Check maker's guide or ask an expert if unsure. Right automotive electrical connectors types fit well and work great.

Making Sure Connections Are Tight

Once you pick a connector, attach it firmly with a crimping tool. Check wires are aligned right and connector is tight. Use multimeter to make sure electricity flows fine.

"Finding correct connector part number and brand for your car wire setup is key in any fix or upgrade." - Complete Guide on Electrical Connectors

By doing these steps, you can safely change car wiring connectors types so your car works well and safely.

Things to Think About and Expert Tips

When using car electrical connectors, know the common mistakes. Follow these expert tips for good performance.

Mistakes People Make

Picking Wrong Connectors

Choosing wrong connectors can cause problems. Always match them to your car's needs. Experts say connector quality depends on materials and design. Right connectors work safely. Avoid extra costs by checking guides or asking experts.

Bad Connection Methods

Bad connection methods can cause weak contact. Use right tools for crimping and securing. Loose connections can overheat. Experts warn that small movements cause wear called fretting corrosion. Secure connectors well to stop this.

Maintenance Advice

Check Connectors Often

Look at your connectors often for damage or rust. Broken pins mean you need new ones. Experts say vibrations cause fretting corrosion too. Regular checks catch problems early, keeping your car safe.

Keep Connectors Clean and Dry

Clean, dry connectors stop rust and signal loss. Use grease to protect them from weather harm. This keeps them working well, says experts. Clean connectors make sure electricity flows right, lowering failure risk.

By avoiding mistakes and doing these maintenance tasks, your car's electrical parts will work safely and last longer.

To find and change car wiring connectors, do these steps: know connector types, use correct tools, and make sure connections are tight. Regular checks stop electric problems and keep cars safe. Look for worn parts and clean them to work well. If you face trouble or feel unsure, ask experts for help. Good connectors and expert advice can make your car work better, giving you a safe drive.

See Also

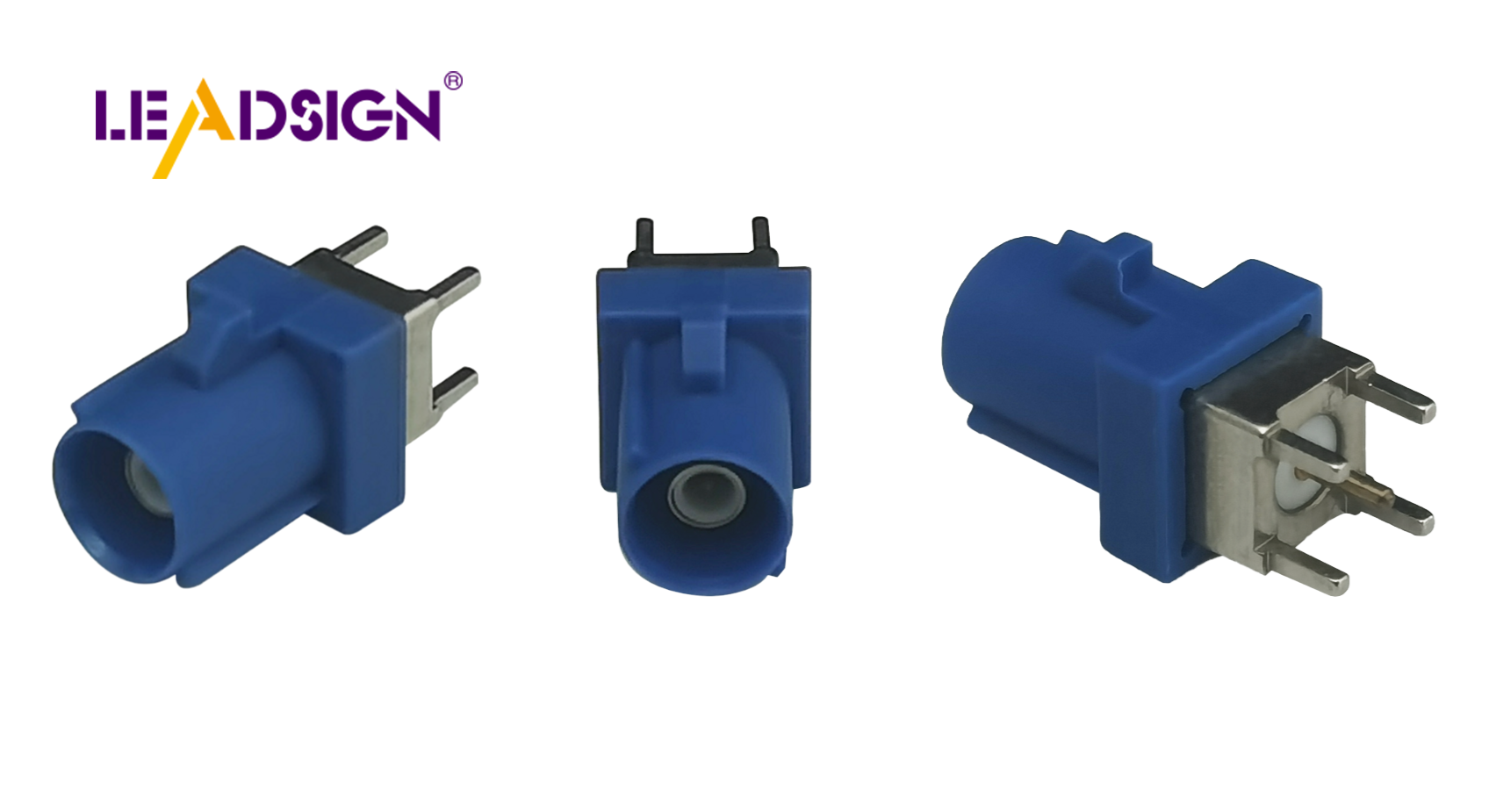

Exploring HSD Connectors in Automotive Sector

Navigating Ford Fakra Connectors

Significance of Fakra Connectors in Contemporary Cars