How to Identify and Replace Automotive Wire Connectors

Maintaining the functionality of your car's electrical components is crucial. Automotive wire connectors can become corroded and deteriorate over time, leading to electrical issues. Properly identifying and replacing these connectors ensures safety. Understanding the different automotive wire connectors types helps you select the appropriate ones, preventing further complications. Regular inspections and timely replacements keep your vehicle operating smoothly.

Understanding Automotive Wire Connectors

Knowing different automotive wire connectors is key for your car's electrical health. Each type has a job to keep connections strong and working well.

Types of Automotive Wire Connectors

Blade Connectors

Blade connectors are very common in cars. They are easy to use and dependable. They have a flat metal piece that fits into a slot, making a solid link. These are great when you need to disconnect quickly.

Butt Connectors

Butt connectors are also popular in cars. They connect two wires end-to-end smoothly. Use them for fixing or extending wires in your car. Their design keeps the connection safe from outside harm.

Ring Connectors

Ring connectors help attach securely to terminal posts. You see them with batteries or grounding tasks. The ring shape lets bolts or screws hold them tight, making them very reliable.

Uses and Jobs

Knowing what these connectors do helps pick the right one for your needs.

Electrical Connectivity

Types like T-tap wire connectors and block connectors keep connections strong in tough conditions inside cars, keeping systems running well.

Signal Transmission

Signal transmission is vital too. Connectors like Scotch Locks join wires fast without stripping or soldering, perfect for quick fixes, ensuring signals move well through your car.

Power Distribution

Power distribution needs the right connector types like butt, spade, and ring terminals for extra safety and smooth power flow everywhere in your car, stopping problems and keeping it running well.

By knowing these connector types and uses, you can choose wisely when checking or changing them in your vehicle, keeping its electrical system steady and effective.

Finding Bad Wire Connectors

Finding bad wire connectors is important. It keeps your car's electricity working well. Knowing what damage looks like helps you fix problems early.

Damage Signs

Rust

Rust looks like green or white powder on connectors. It stops electricity from flowing right. Check for rust often, especially where it's wet.

Broken Wires

Broken wires show harm. They might cause sparks or fires. Look at your wire connectors for broken parts. Change bad wires fast to stay safe.

Loose Parts

Loose parts can make lights flicker or systems fail. Tighten loose connectors to fix them.

Checking Tools

Multimeter

A multimeter checks electrical links. It shows voltage and resistance levels. Use it to test your wire connectors quickly.

Looking Tools

Tools like magnifying glasses help see hard spots. They find rust, broken wires, and loose parts easily. Regular checks keep your car's electric system good.

Expert Tip:

Car Wiring Expert: "Solder wire connectors are great for fixing car systems."

By knowing these signs and using tools, you keep your car's electric system healthy. Regular checks stop big fixes and keep your car running well.

Steps to Replace Wire Connectors

Changing automotive wire connectors is easy. It helps keep your car's electrical system working well. Follow these steps to do it right.

Safety First

Be safe before you start to avoid accidents.

Disconnect the Battery

First, take off the battery connection. This stops electric shocks and short circuits. Find the negative end and use a wrench to remove it. Keep the cable away from the battery so it doesn't reconnect by mistake.

Use Safe Tools

Use tools with insulation for safety. These tools stop electricity from passing through them, keeping you safe. Check your tools for any damage before using them.

Take Out Old Connectors

After safety steps, remove old connectors.

Cut and Strip Wires

Use a cutter to cut bad wire parts. Cut about an inch away from the connector so you have enough wire left. Then strip half an inch of cover off each wire end with a stripper tool to show metal for new connections.

Remove Bad Connectors

Gently pull off old connectors from wires. If stuck, use pliers carefully without breaking wires. Look at wires for damage or rust. If damaged, cut more until you see clean wire.

Put in New Connectors

Now put in new connectors after removing old ones.

Pick Right Connector

Choose the right connector type for your wires. Think about wire size and what you'll use it for. Use butt connectors to join wires or ring ones to attach wires securely on posts.

Crimping Method

Put stripped wire into a new connector. Use a crimping tool to press it tightly in place so it stays secure and connected well.

Test Connection

Test after putting in new connector by reconnecting battery and checking with multimeter for good flow of electricity without loose parts.

Expert Insight:

"Fixing car electrical connectors is simple and saves money instead of changing all wiring."

By following these steps, change automotive wire connectors easily and maintain your car's electrical health regularly.

Tips for Taking Care of Wire Connectors

Keeping your car's wire connectors in good shape is important. It helps the car's electrical system work well. Regular checks and protection can stop problems and make connectors last longer.

Regular Checks

Checking often helps keep wire connectors healthy. By looking at them a lot, you find problems early and save money on repairs.

Maintenance Schedule

Make a plan to check wire connectors. Set reminders every few months. During checks, look for damage or wear signs. This way, you find issues before they get bad.

Spotting Wear Early

Look for wear signs like color changes or rust spots. These mean a connector might break soon. Find these signs early to change connectors before causing trouble.

Protection Steps

Protection makes wire connectors last longer. Using right ways and stuff keeps connections strong and lasting.

Heat Shrink Tubing Use

Heat shrink tubing protects wire connectors well. It seals them from water and dirt. This stops rust and makes them last longer. Always use heat shrink when adding new connectors.

Dielectric Grease Use

Dielectric grease is also good protection. Put it on connectors to stop water and rust. It keeps connections tight and safe, making disconnecting easy too.

Pro Tip: "Using heat shrink makes connections tight and safe for long use."

By following these tips, take care of your car's wire connector types well. Regular checks and protection keep the electrical system working great.

To keep your car's electrical system working well, follow these steps: find bad connectors, replace them with the right ones, and make sure they are secure. Regular checks are important. They help you find problems early and save money on repairs. Be safe by using tools with insulation and disconnecting the battery before starting work. Always do repairs carefully. By picking good connectors and taking care of them, you make sure your car's electrical system is reliable and works efficiently.

See Also

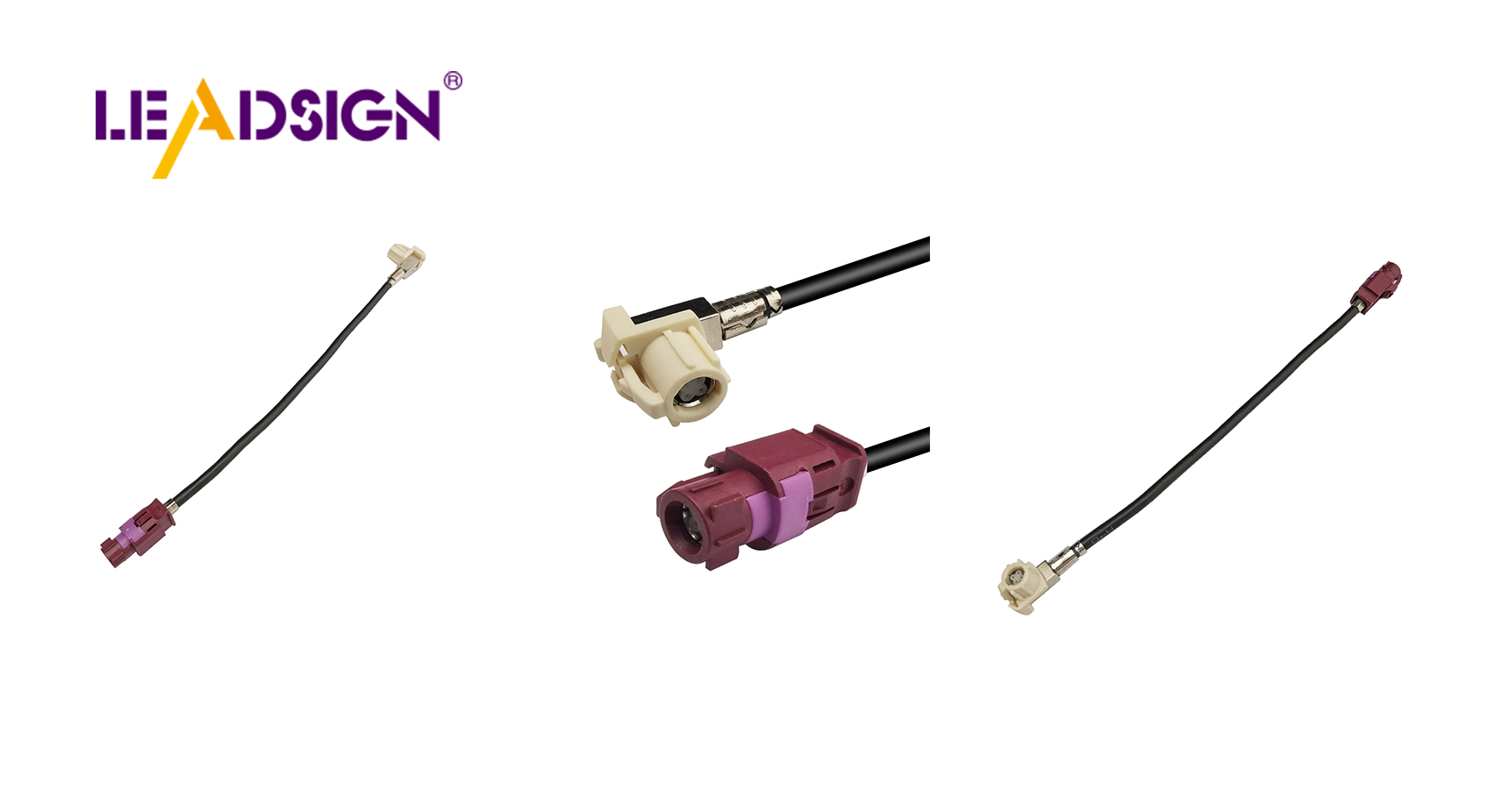

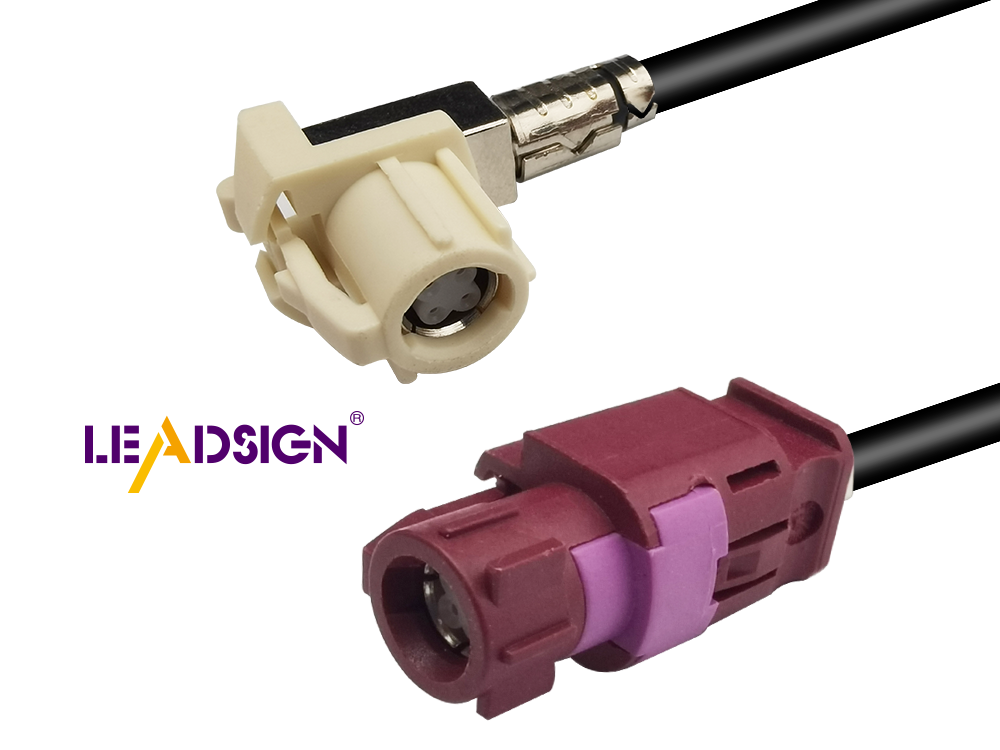

Navigating Ford Fakra Connections

Fundamentals of HSD Connections in Auto Sector

Significance of FAKRA Connections in Auto Uses