How to Identify and Replace Automotive Electrical Connectors Types

Understanding automotive electrical connectors types is crucial for your vehicle. These connectors can encounter issues such as rust, broken components, and melted plastic, which may lead to electrical failures. Addressing faulty connectors ensures your car operates efficiently and safely. Resolving these problems mitigates risks and enhances your vehicle's performance. Regularly inspecting and replacing connectors can save money on repairs and guarantee a reliable driving experience.

Identifying Automotive Electrical Connectors Types

Knowing different automotive electrical connectors is important for your car. These connectors have various shapes and jobs.

Types of Automotive Electrical Connectors

Blade Connectors: Blade connectors are common in cars because they are easy to use. They have a flat piece that fits into a slot. This makes them quick to connect and disconnect, perfect for frequent maintenance.

Pin Connectors: Also called pigtail connectors, pin connectors work well with high power like headlights. They have pins that fit into sockets for a strong connection. They help move data and carry high voltage safely.

Butt Connectors: Butt connectors join two wires easily without soldering. They make connections reliable and strong, which is key for the car's electrical system.

Tools for Identification

To find the right connector type, you need special tools:

Multimeter: A multimeter checks electrical connections by measuring voltage, current, and resistance to spot problems.

Connector Identification Guide: A guide helps you identify connector types with pictures and descriptions.

Common Signs of Faulty Connectors

Spotting bad connectors can stop more damage:

Visual Inspection: Check connectors often for damage like rust or broken parts. These show a bad connector needing change.

Electrical Testing: Use a multimeter to check if connectors work right by testing voltage and current flow. Bad results mean the connector might need replacing.

By knowing these types of automotive electrical connectors and using proper tools, you can keep your car's electrical system in good shape. Regular checks and timely fixes will keep your vehicle safe and working well.

Steps to Replace Car Electrical Connectors

Changing car electrical connectors needs a few steps. Each step helps make sure the connection is safe and works well. Follow these steps to change connectors right.

Getting Ready

Collecting Needed Tools

Before starting, gather all needed tools. You will need a multimeter, wire cutters, crimping tools, and soldering gear. Having these tools ready makes the job easier and faster. A guide for connector types can help you pick the right one.

Safety First

Safety matters when working with electricity. Unplug the car battery to stop shocks or short circuits. Wear safety glasses and gloves to stay safe from accidents. Make sure your work area is bright and tidy to avoid mistakes.

Taking Out Old Connectors

Unhooking the Battery

Start by unhooking the battery. This step keeps you safe from electric dangers. Find the battery ends and use a wrench to loosen them. Take off the negative end first, then the positive one.

Removing the Connector

Find the bad connector next. Carefully take it off by pressing its tab or unscrewing it, based on type. Notice keyways and tabs on it as they help align during setup. Remember pin count, shape, and size for later.

Putting in New Connectors

Picking the Right Connector

Pick a good replacement connector. Match keyways, tabs, and pins with old ones. Think about your car's make, model, and year for fitment. This step is key for smooth connection and function.

Crimping and Soldering Steps

After getting the right connector, start crimping and soldering wires into it securely using tools provided earlier; this adds strength ensuring durability of connections made here today!

By doing these steps carefully every time needed ensures long-lasting performance without issues arising unexpectedly down road ahead!

Checking the New Connection

Once you put in the new connector, make sure it works well. Testing helps find problems early and stops future trouble.

Hooking Up the Battery

Connect Battery Ends: First, hook up the battery ends. Attach the positive end first, then the negative. Use a wrench to tighten them well. This step gives power back to your car's system.

Ensure Tight Connections: Check that all parts are tight and secure. Loose parts can cause electric problems or shorts. A tight fit keeps electricity flowing smoothly.

Doing a Function Test

Start the Car: Turn on the car to see if everything works right. Watch for warning lights on the dashboard. These lights show if there’s a problem with the new part.

Try Electrical Parts: Use things like headlights, blinkers, and radio. Make sure they work without flickering or stopping. This shows that power is moving well through the new connector.

Use a Multimeter: Check voltage and current at connection points with a multimeter. Compare these numbers to what your car should have. If numbers don’t match, there might be an install issue.

Look for Odd Signs: Watch for sparks, smoke, or burning smells which mean danger needs fixing fast to stay safe.

By doing these checks, you keep your connector working great! Regular tests help your car run safely and smoothly.

Tips and Things to Think About

Picking the right automotive electrical connectors and taking care of them keeps your car's electric parts working well. Here are some easy tips.

Picking Good Connectors

Choosing strong connectors helps your car last longer.

What They're Made Of

Look for connectors made from tough stuff. Copper and brass are good because they carry electricity well and don't rust easily. These help keep a solid connection, stopping electric problems. Stay away from weak materials that break down fast and might make your car unsafe.

Best Brands to Buy

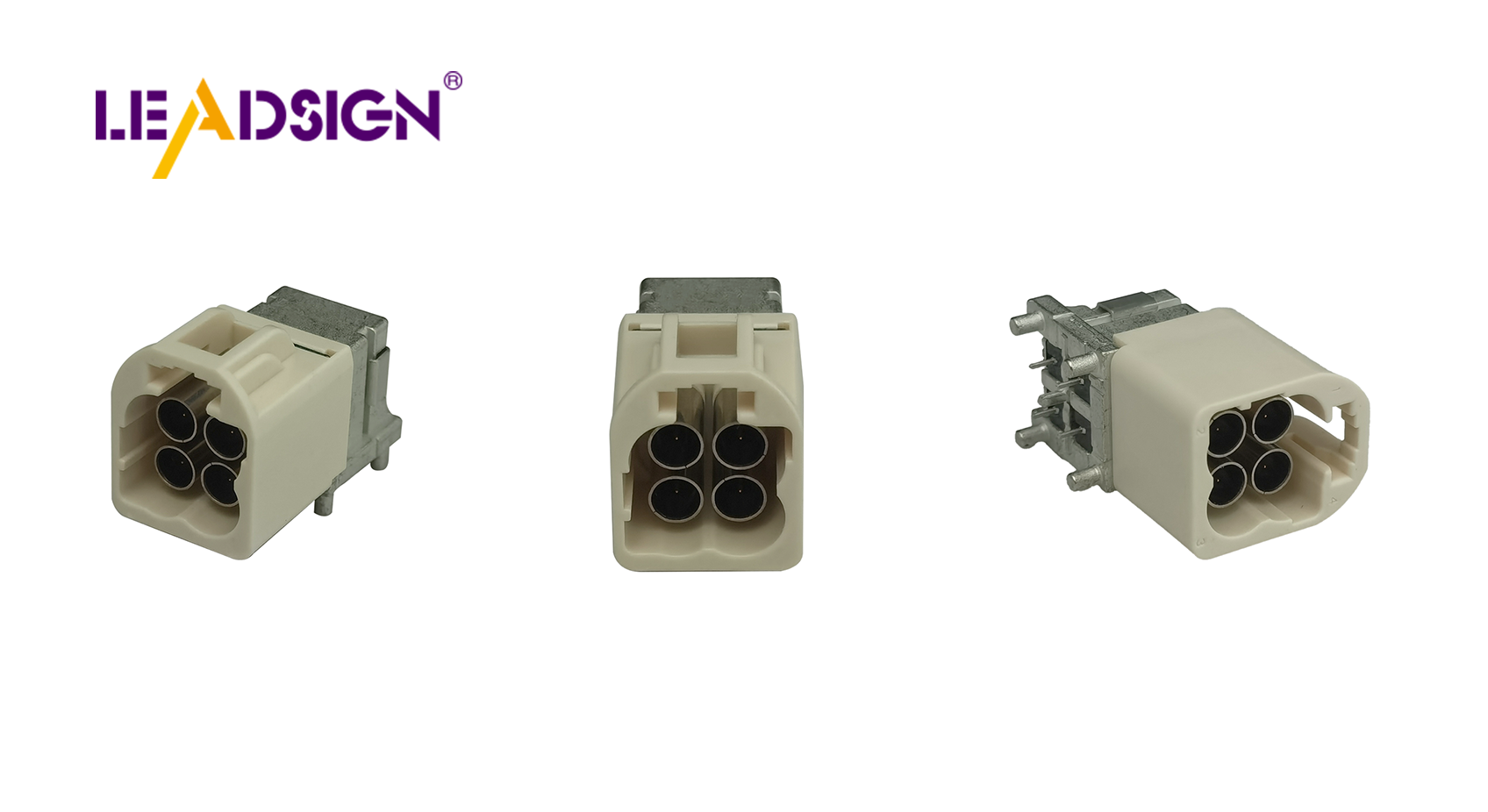

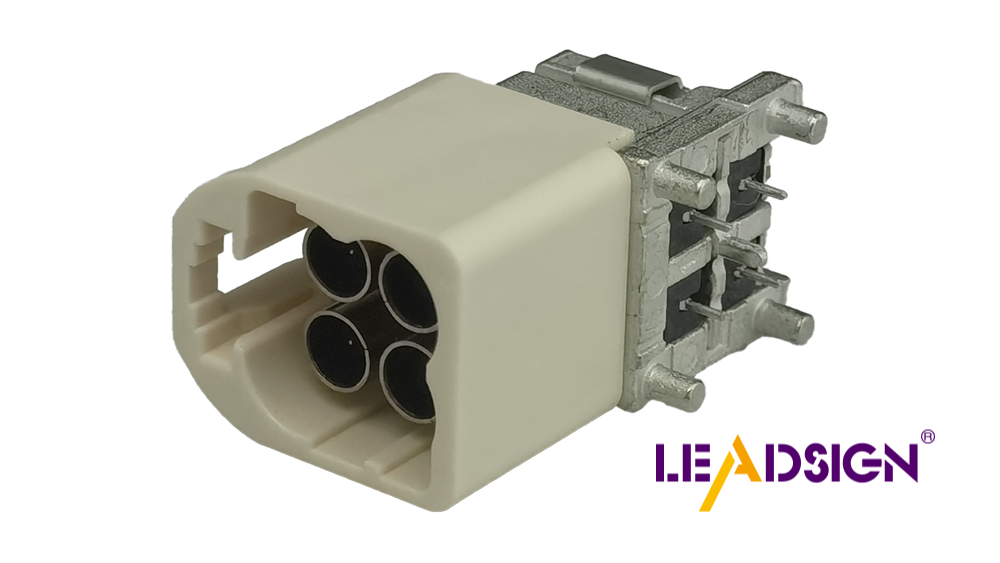

Go for brands known for being reliable. Brands like LEADSIGN have good quality connectors. Their Mini FAKRA ones send data fast and fit in small spaces while staying strong. Trusted brands give you connectors that work well in different situations.

Taking Care of Electrical Connectors

Looking after your car's connectors stops problems and makes them last longer.

Check Them Often

Look at your connectors regularly to spot wear or damage. Watch out for rust, broken parts, or melted bits. If you find these early, you can fix them before bigger issues happen.

How to Clean Them

Keep connectors clean so they work best. Use a soft brush or air spray to get rid of dirt. For tough spots, use a gentle cleaner but dry them well after cleaning to avoid water problems. Cleaning often stops dirt from messing up connections.

Expert Tip: "Testing connectors can be tricky because it's hard to tell if the problem is with the wire or the connector itself."

By using these simple tips, you keep your car's electrical system safe and running smoothly with good-quality connectors and regular care.

Check your car's connectors often for damage. Use strong materials like copper or brass so they last longer. Clean them regularly to keep them working well. If you find tough problems or feel unsure, ask an expert for help. This keeps your car's electrical system safe and reliable. By doing these things, you make your car work better and stay safe, giving you peace of mind while driving.

See Also

Exploring HSD Connectors in Automotive Sector

Navigating Ford Fakra Connectors

The Significance of FAKRA Connectors in Auto Uses