A Guide to Identifying Faulty Vehicle Connectors and Replacing Them

Car connectors, including various auto wire connector types, are crucial for your car's electrical system. These tiny parts help different systems, like lights and safety features, function effectively. Ignoring bad connectors can lead to significant issues; for instance, 45% of high-voltage connector problems result in electrical failures, which can impact essential safety systems. Environmental factors such as water exposure or extreme temperatures can damage connectors over time. By identifying and repairing faulty connectors, you can prevent costly repairs and ensure your car remains safe and operates smoothly.

Key Takeaways

Regularly inspect vehicle connectors for signs of damage, such as rust or loose connections, to prevent costly repairs.

Use essential tools like a multimeter and wire strippers to accurately diagnose and fix faulty connectors.

Always prioritize safety by disconnecting the battery and wearing protective gear before starting any repairs.

Choose the right type of connector for your vehicle, such as crimp or soldered connectors, to ensure a secure and lasting connection.

Apply dielectric grease to connectors to protect against moisture and rust, extending their lifespan.

Test all connections thoroughly after repairs to ensure everything is secure and functioning properly.

Routine maintenance of vehicle connectors can save time and money, keeping your car's electrical system reliable.

How to Spot Faulty Vehicle Connectors

Finding faulty vehicle connectors is important for your car's health. Let’s go over the signs, tools, and connector types to help you fix them.

Signs of Bad Connectors

Bad connectors often show easy-to-spot problems. Knowing these can save time and trouble. Look out for:

Random electrical problems or system failures: If lights flicker or systems stop working suddenly, a bad connector might be causing it. This happens due to loose contact or broken wires.

Visible wear: Look for rust, burns, or torn wires. Rust forms from water exposure, while burns happen from overheating. Torn wires mean they’ve worn out with use.

Loose or melted connectors: A loose connector interrupts electricity flow. Melted ones mean overheating and need fixing fast.

Catching these early stops bigger issues later.

Tools to Check Connectors

The right tools make finding bad connectors easier. You’ll need:

Multimeter: Use this tool to check if electricity flows properly. It helps find broken wires quickly.

Inspection tools: Use a flashlight or magnifying glass to see hidden damage like rust or cracks.

Circuit testers: These test power flow easily and give quick results.

For advanced checks, try an Automotive Diagnostic Testing Components Kit with different parts for many uses. For durability, use Automotive Connector Breakout Leads, which last longer and save time.

Types of Auto Wire Connectors

Picking the right connector is key for repairs. Here are common choices:

Crimp connectors: These are strong and easy to use for most car fixes.

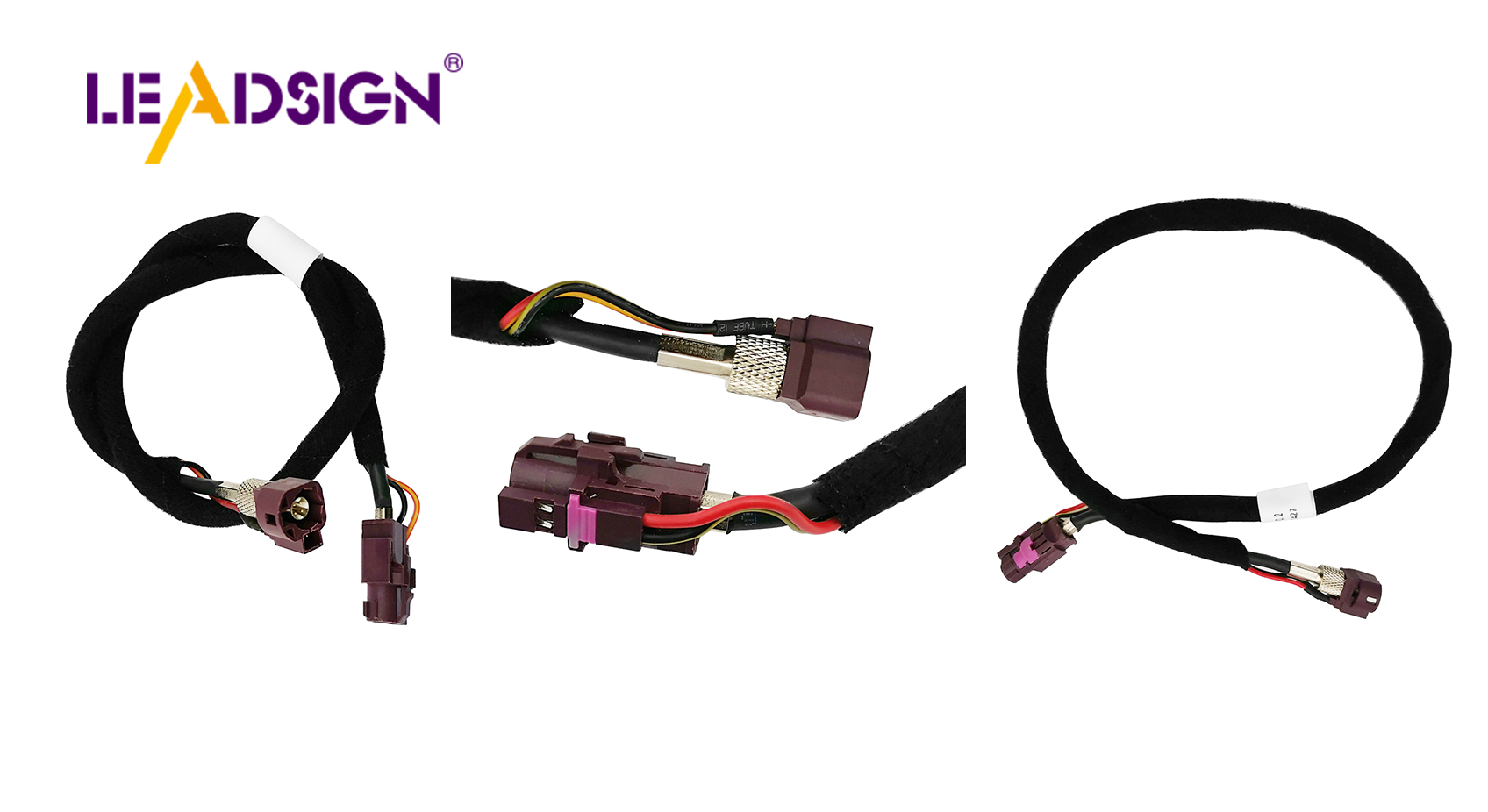

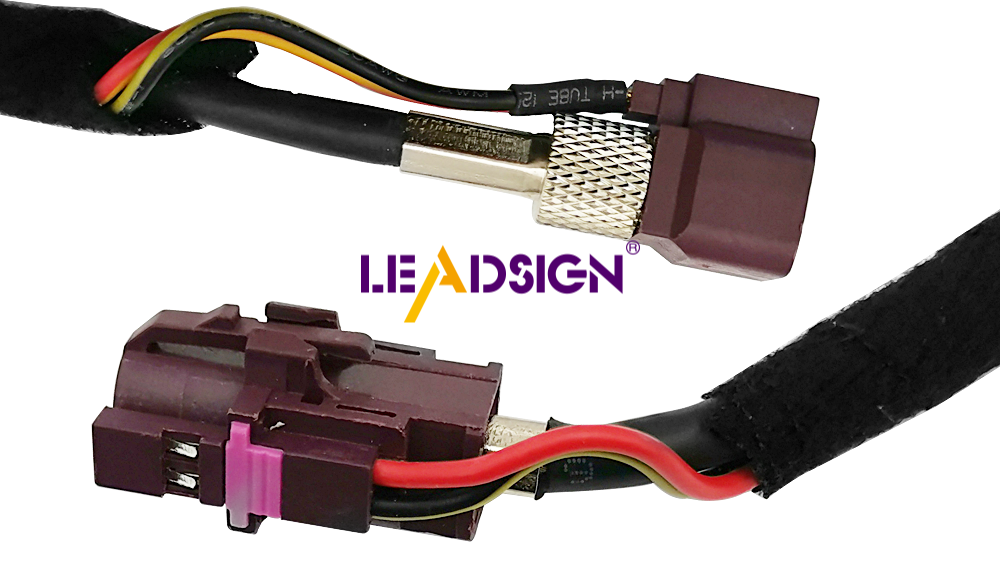

HSD connectors: High-Speed Data (HSD) connectors work in modern cars for cameras or USBs. They have locks that keep connections secure.

Soldered connectors: For permanent fixes, soldered ones are best as they handle vibrations well.

Knowing these auto wire connector types helps you pick the right one for your repair job!

Getting Ready to Replace Faulty Connectors

Fixing faulty connectors needs planning. Focus on safety and gather tools. Follow these steps carefully.

Important Safety Steps

Safety is the most important thing when fixing car wires. These tips will help you stay safe:

Unplug the battery to avoid shocks.

Disconnect the battery before starting work. This stops electricity from flowing while you fix things. It keeps you safe from shocks and short circuits. Always remove the negative terminal first for safety.

Wear gloves and goggles for protection.

Gloves keep your hands safe from sharp wires or hot parts. Goggles protect your eyes from sparks or flying debris. These simple steps prevent painful injuries.

"Staying safe while working on car connectors is very important. It reduces risks and makes repairs easier." – Automotive Experts

Tools and Supplies You’ll Need

Using the right tools makes fixing connectors faster and better. Here’s what to have:

Wire strippers and crimpers for neat work.

Wire strippers remove wire coverings without damage. Crimpers attach connectors securely to wires, making a clean connection.

Replacement connectors that fit your car’s system.

Pick connectors that match your car’s needs exactly. Wrong ones can cause bad connections or failures. For new cars, use auto wire connector types like crimp or HSD connectors for good results.

Heat shrink tubes or tape for insulation.

After connecting, cover wires with heat shrink tubing or tape. This protects against water and stops short circuits. Heat shrink tubing looks neat and lasts longer.

"Good tools make repairs last longer and keep car systems working well." – Automotive Experts

By preparing well, you can replace faulty connectors safely and easily. Take time to check everything before starting the repair job!

Step-by-Step Guide to Replacing Faulty Connectors

Fixing a bad connector can seem hard. Breaking it into steps makes it easier. Follow this guide to fix it properly.

Taking Out the Old Connector

Finding the faulty connector and its wires.

First, find the damaged connector. Look for signs like burns, rust, or loose wires. If you can't see the problem, use a multimeter to check electricity flow. A bad connector stops electricity from flowing correctly. Once found, follow its wires carefully so you don’t cut or disconnect the wrong one.

Cutting or removing the broken connector safely.

Use wire cutters or pliers to take out the bad connector. Cut close to it without harming the wire covering. If clips or screws hold it in place, loosen them gently. Don’t pull on wires directly; this could damage them more. Work slowly for a clean removal.

"Removing connectors carefully avoids extra damage and saves repair time." – Automotive Experts

Adding the New Connector

Preparing wire ends for connection by stripping insulation.

After removing the old part, strip about half an inch of insulation off each wire end using a wire stripper. Make sure exposed wires are clean and not rusty. Twist wire strands together tightly for a strong connection before attaching them to your new connector.

Securing the new connector by crimping or soldering.

Pick a suitable connector for your car’s system needs. Crimp connectors work well for most fixes, while soldered ones are better for permanent repairs. Insert stripped wires into your chosen connector and secure with a crimping tool or soldering iron as needed. Let everything cool before moving forward with testing.

"Strong connections prevent future electrical problems from happening." – Automotive Experts

Testing Your Work

Hooking up the battery and checking if everything works.

Reconnect your car battery after installing the new part—positive terminal first, then negative terminal next. Turn on your car and test if repaired systems work properly now.

Making sure everything stays connected firmly.

Gently wiggle wires to confirm they’re attached securely without movement issues causing trouble later on! If all works fine during tests—you’ve fixed it! If not—recheck steps taken earlier until resolved fully!

"Testing ensures repairs last longer without causing future troubles!" – Automotive Experts

Follow these simple steps carefully when replacing faulty connectors yourself confidently!

Tips for Maintaining Vehicle Connectors

Taking care of vehicle connectors keeps your car running well. A little maintenance now can prevent expensive repairs later. Here are some easy tips to help maintain them.

Preventing Future Problems

Check connectors often for damage or wear.

Make it a routine to inspect your connectors regularly. Look for rust, melted parts, or cracks. These signs mean there could be trouble soon. Spotting problems early helps you fix them before they get worse. Use a flashlight to see hidden issues clearly. Regular checks save both time and money.

"Checking connectors often stops big electrical problems from starting." – Automotive Experts

Apply dielectric grease to stop rust.

Rust is bad for vehicle connectors and weakens their performance. Water and dirt can cause rust over time. Dielectric grease creates a shield that blocks moisture and dirt. This simple step keeps your connectors clean and working longer.

Pro Tip: Put a small amount of dielectric grease on connector pins before plugging them in to protect against water.

Avoiding Common Errors

Match the connector with the correct wire size.

Using the wrong connector can cause loose connections or failures. Always check if the connector fits the wire size properly. A mismatch might lead to overheating or poor signals. Take time to ensure compatibility before connecting wires.

"Choosing the right connector ensures your system works reliably." – Automotive Experts

Test connections before putting everything back together.

Before finishing, gently pull on wires to check they’re secure. Loose wires can create problems later or stop systems from working entirely. Double-checking saves you from fixing things again later on.

"Spending seconds checking now avoids hours of fixing later." – Automotive Experts

Follow these steps to keep your vehicle connectors in great shape! Regular care prevents problems and keeps your car’s electrical system dependable.

Finding and fixing bad connectors is important for your car. Look for problems early by checking them visually or testing electricity flow. This can save money and keep your car working well. Follow simple steps and safety tips to make repairs easier. Checking connectors often and using the correct ones stops future issues. Take care of your car now—small actions today mean safer, reliable driving later.

See Also

Understanding Ford Fakra Connectors: A Complete Overview

Exploring Fakra Connectors Used in Honda Cars

An In-Depth Look at HSD Connectors